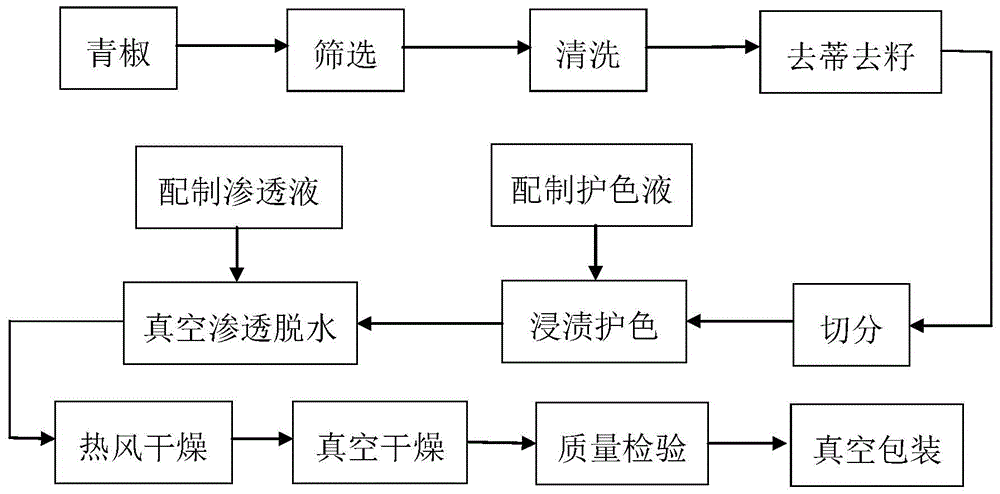

Method for combined drying of green peppers

A technology that combines drying and green peppers, applied in the fields of food preservation, fruit and vegetable preservation, food science, etc., can solve the problems of unguaranteed product quality, unattainable green pepper products, low moisture content, etc., and achieves high drying efficiency and excellent quality. , the effect of reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Step 1. Pre-treat the green peppers. Choose fresh green peppers with uniform color, thin skin, no disease spots, and no rot. Wash them with clean water, remove the stalks and internal seeds of the green peppers, drain them and cut them into 4mm strips evenly standby.

[0055] Step 2: Carry out color protection treatment to the green peppers, and perform color protection treatment on the pretreated green peppers. The color protection solution is composed of the following components: 0.20% citric acid, 0.30% ascorbic acid, 0.4% zinc gluconate, and the rest is water. The sum of the contents of the above components is 100%. Soak and protect the color according to the liquid-to-material ratio of 3:1, the solution temperature is 20°C, and the color-protecting treatment time is 20 minutes, then spray the green peppers after the color-protecting treatment with clean water and drain.

[0056] Step 3, vacuum osmosis dehydration, the green pepper after the color protection treatm...

Embodiment 2

[0062] Step 1. Pre-treat the green peppers. Choose fresh green peppers with uniform color, thin skin, no disease spots, and no rot. Wash them with clean water, remove the stalks and internal seeds of the green peppers, and cut them into 4-8mm evenly after draining. the filamentary spare;

[0063] Step 2: Carry out color protection treatment to the green peppers, and perform color protection treatment on the pretreated green peppers. The color protection solution is composed of the following components: 0.30% citric acid, 0.40% ascorbic acid, 0.50% zinc gluconate, and the rest is water. The sum of the contents of the above components is 100%. Soak and protect the color according to the ratio of liquid to material 5:1, the temperature of the solution is 30°C, the time for color protection treatment is 40min, and then the green peppers after the color protection treatment are sprayed with clear water and drained; after the color protection treatment, It can keep the chlorophyll ...

Embodiment 3

[0070] Step 1: Pre-treat the green peppers, choose fresh green peppers with uniform color, thin skin, no disease spots, and no rot, wash them with clean water, remove the stalks and internal seeds of the green peppers, drain and cut them into 6mm strips evenly standby;

[0071]Step 2: Carry out color protection treatment on green peppers, and carry out color protection treatment on pretreated green peppers. The color protection solution is composed of the following components: 0.25% citric acid, 0.35% ascorbic acid, 0.45% zinc gluconate, and the rest is water. The sum of the contents of the above components is 100%. Soak and protect the color according to the ratio of liquid to material 4:1, the temperature of the solution is 25°C, the time for color protection treatment is 30min, and then the green peppers after the color protection treatment are sprayed with clear water and drained; after the color protection treatment, It can keep the chlorophyll in the green pepper to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com