No-residual vertical type household noodle maker

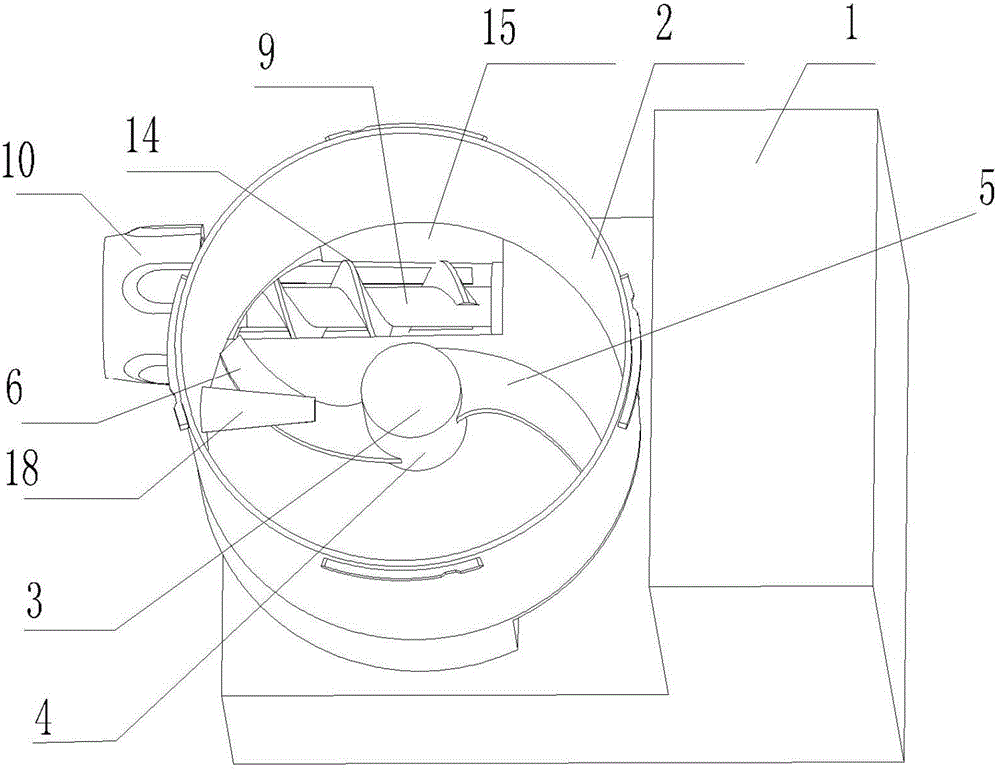

A domestic noodle machine, no residue technology, applied in dough extruder, mixing/kneading with vertical installation tools, application, etc., can solve the problem of noodle flocculation or dough residue, flocculation or dough residue, and reduce extrusion efficiency and other problems, to achieve the effect of not easy to stick to residue, easy to drive and connect, and smooth into the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

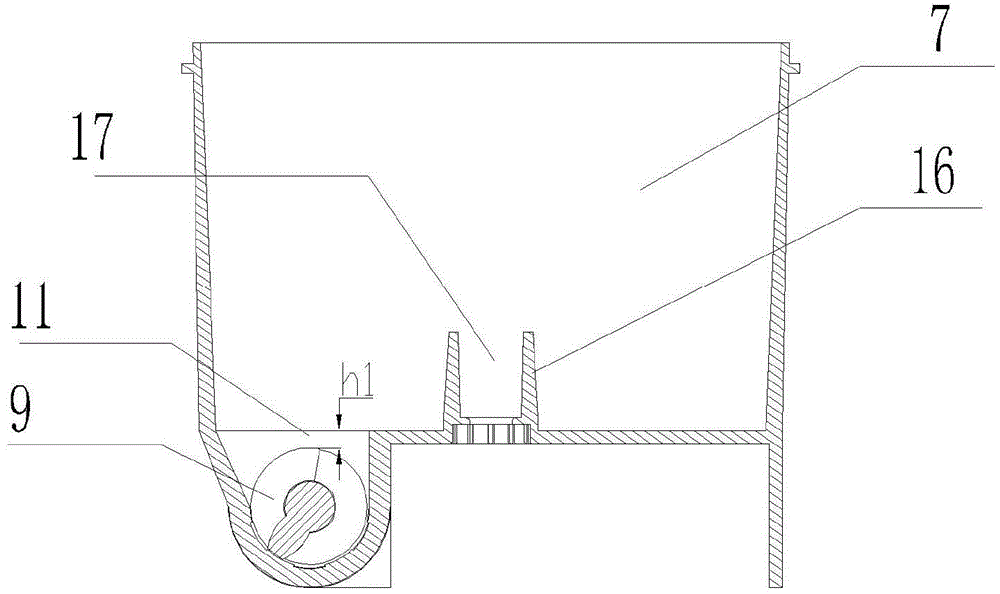

[0060] like Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the cross-section of the noodle inlet 11 is an arcuate structure, and the connection between the noodle inlet 11 and the side wall of the mixing cup 2 forms an arcuate arc edge. The side wall of the extruding barrel intersects with the bottom of the mixing cup to form a bow-shaped chord, and the two ends of the arc are respectively connected to the two ends of the chord, and the slope 15 extends downward along the arc to the material propulsion chamber 13 . The advantage of such setting is: the bow-shaped noodle inlet 11 can ensure that under the premise of the circular mixing chamber 7, the area of the noodle inlet 11 is maximized, and the proportion of the stirred dough entering the noodle inlet 11 per unit time is the largest. Thereby improving the efficiency of dough feeding. In addition, the bow-shaped arc edge is also conducive to the falling of the dough. There is no dead ...

Embodiment 3

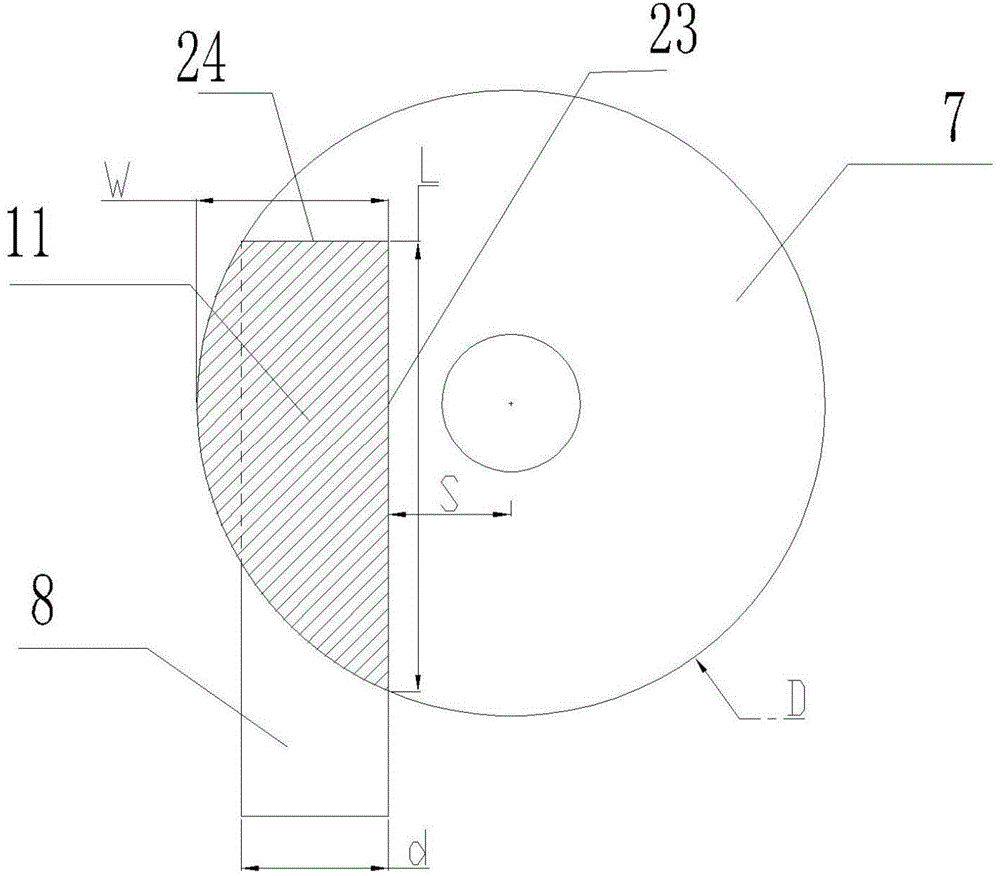

[0062] like Image 6 As shown, the difference between this embodiment and Embodiment 1 is that the mixing cup in this embodiment is square, the noodle inlet 11 is arranged along any side of the square, and the long straight side 23 is parallel to the side , and intersects the adjacent two sides. The advantage of this setting is that the noodle inlet 11 is arranged along the side of the square, so that the length of the noodle inlet 11 is maximized, thereby increasing the ratio of noodle inlet per unit time and improving the efficiency of noodle forming. The square mixing cup is disturbing. The effect of flow makes the stirring effect more fully.

Embodiment 4

[0064] like Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that the stirring cup in this embodiment is a regular hexagon, the noodle inlet 11 is arranged along any side of the regular hexagon, and the long straight sides 23 are parallel intersects the side, and intersects the adjacent two sides. The advantage of such setting is: the regular hexagonal stirring cup 2 makes the strength of the stirring cup 2 high, and it is not easy to deform or vibrate during the stirring process, which reduces the vibration caused by the stirring rod 3 during the stirring process, reduces the noise, and makes The noodle machine runs more smoothly. In addition, the distance between each side and the rotation circle of the stirring rod 3 changes. Therefore, when the stirring rod 3 rotates, the side of the regular hexagon of the stirring cup can play a role in retaining the ribs and improve the flour quality. , The mixing efficiency of water, the regular hexagonal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com