Novel conveying roller used for silicon wafer chained texturing

A chain and roller technology, which is applied in the field of silicon wafer texturing equipment, can solve problems such as uneven suede surface, achieve uniform suede surface, reduce uneven corrosion, and solve the effects of roller marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

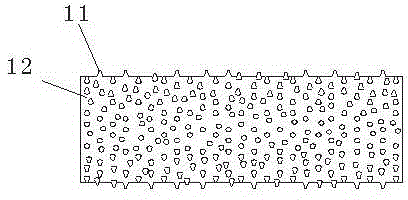

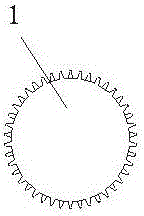

[0017] Example: figure 1 Be a kind of device structure of the present invention, transmission roller 1 is cylindrical structure 12, and the diameter of cylindrical structure 12 is 3 centimeters, and length is 150 centimeters, and cylindrical structure 12 is provided with needle-like protrusion 11, and needle-like protrusion The bottom of 11 is circular, and the needle-like protrusions 11 are randomly distributed on the surface of the cylindrical structure 12. The height of the needle-like protrusions 11 is 1 mm, and the average distance between the needle-like protrusions 11 is 1 mm. One end of the transmission roller 1 is set There are gears. When in use, the gears match the transmission chain on the Schmid texturing machine equipment. The transmission chain drives the roller 1 to rotate, and the silicon wafer is driven forward by the needle-shaped protrusion 11 above the roller 1. The linear speed of rotation at the top of the needle-shaped protrusion 11 of the roller 1 is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com