A finely adjustable four-head eight-station winding machine

A winding machine and eight-station technology, applied in coil manufacturing, electrical components, inductor/transformer/magnet manufacturing, etc., can solve the problems of fewer winding machines, lower production efficiency, scattered coil deformation, etc. The effect of winding accuracy, improving efficiency and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

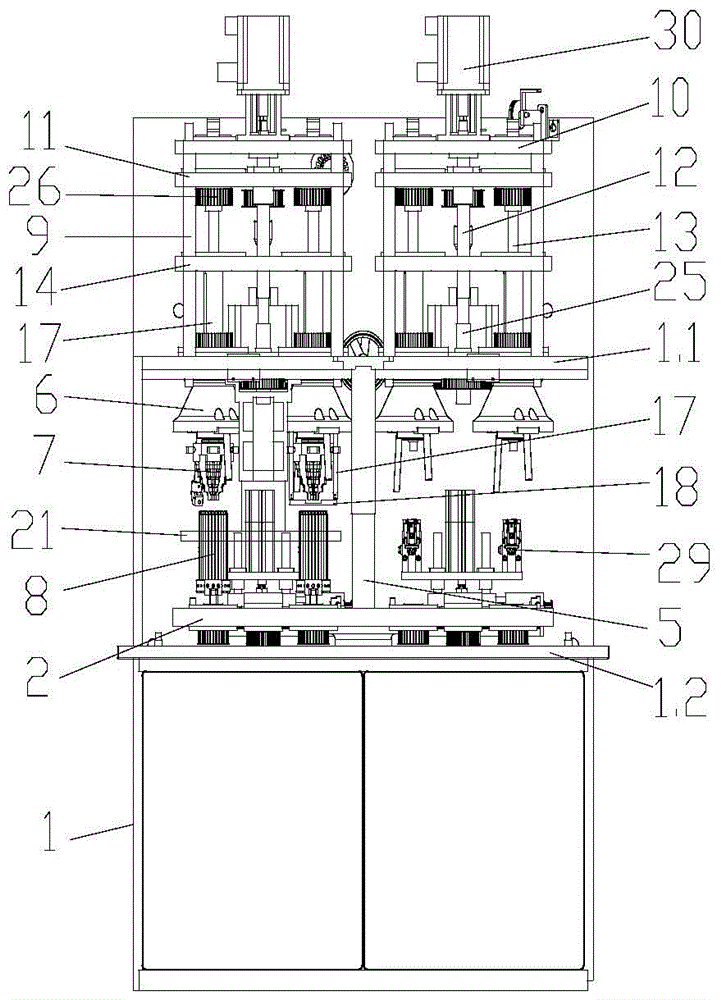

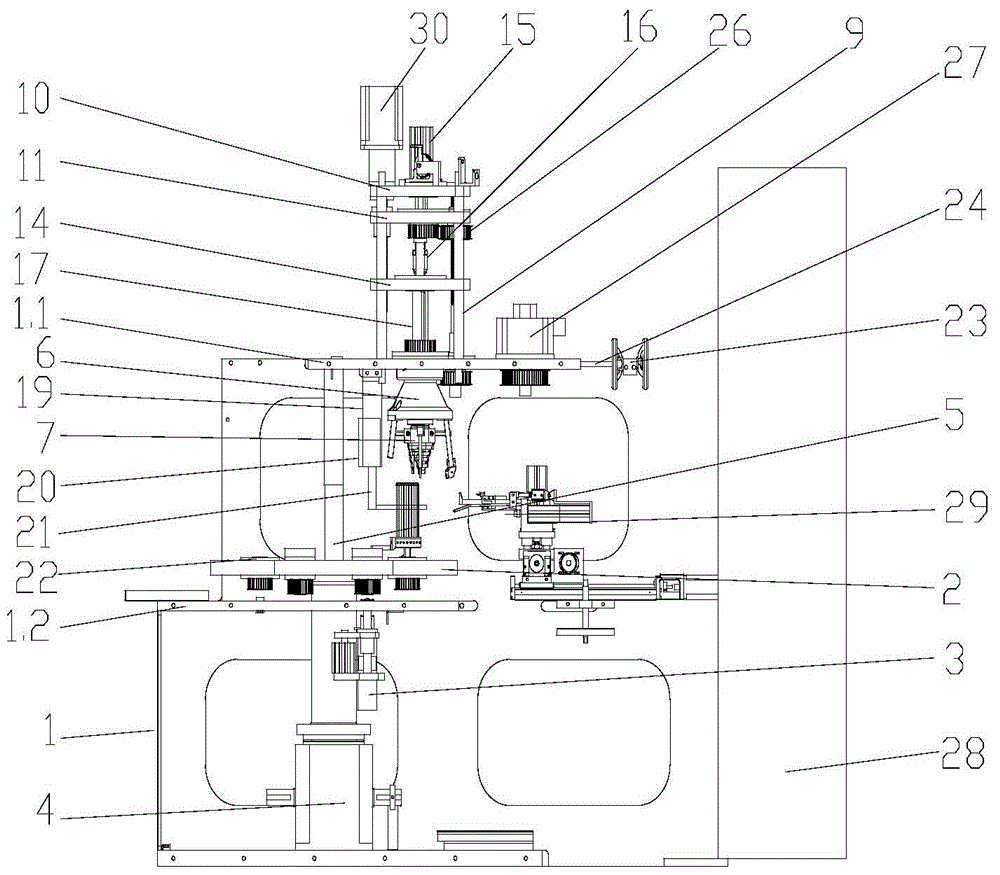

[0015] Such as figure 1 , figure 1 The finely adjustable four-head and eight-station winding machine shown includes a bracket 1, an indexing mechanism 4, a workbench 2, a workbench positioning mechanism 3, a winding mechanism, a wire trimming and pulling mechanism 29, and a bracket 1 Including the upper plate 1.1, the lower plate 1.2 and the side plates on the left and right sides of the upper plate 1.1 and the lower plate 1.2, the workbench 2 is set on the top of the lower plate 1.2, the workbench positioning mechanism 3 and the indexing mechanism 4 are set at the bottom of the lower plate 1.1, The index index mechanism 4 is provided with a transmission support shaft 5, and the transmission support pump 5 passes through the lower plate 1.2 and its upper end is movably connected with the upper plate 1.1. The upper plate 1.1 and the lower plate 1.2 divide the support 1 into three parts: upper, middle and lower. The wire mechanism is arranged on the middle part of the bracket 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com