Prediction apparatus for sound absorption and insulation performance of multilayer material and method

A multi-layer material and performance prediction technology, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, can solve the problems that impedance tubes cannot test the sound absorption and insulation performance of multi-layer composite materials, and achieve easy implementation, convenient operation, and test accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

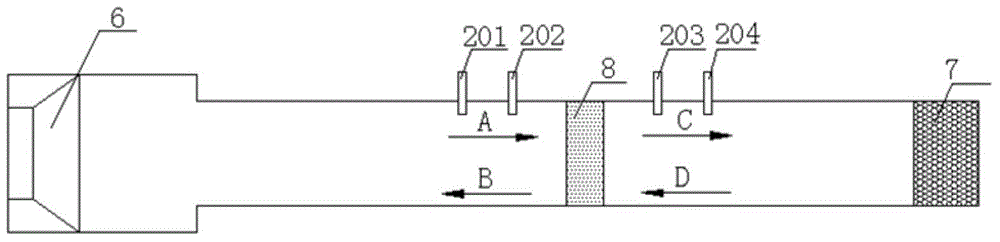

[0024] The device for predicting the sound absorption and insulation performance of multi-layer materials in this embodiment, such as figure 1 shown. It includes an impedance tube 1 with built-in single-layer material to be tested, a microphone group 2, a power amplifier 3, a data acquisition device 4, a computer 5 and a loudspeaker 6. One end of the microphone group 2 is inserted on the upper surface of the impedance tube 1, and the sensors in the microphone group 1 are evenly distributed on both sides of the single-layer material to be tested, and the output end of the microphone group 2 is connected to the input end of the power amplifier 3, the power amplifier The output end of 3 is connected to the input end of the data acquisition device 4, the output end of the data acquisition device 4 is connected to the input end of the computer 5, the output end of the computer 5 is connected to the input end of the loudspeaker 6, and the output end of the loudspeaker 6 outputs whit...

Embodiment 2

[0034] The difference between the multi-layer material sound absorption and insulation performance prediction device in this embodiment and embodiment 1 is that the inner end of the impedance tube 1 is also provided with a sound-absorbing material filler 7, which is used to reduce the influence of the secondary reflected wave D, such as figure 2 shown.

Embodiment 3

[0036] The difference between the device for predicting sound absorption and insulation performance of multi-layer materials in this embodiment and Embodiment 1 is that, in addition to performing amplitude calibration on each microphone, phase calibration should also be performed on each microphone, so that microphones 201 to 204 are at the same time The lag angle is equal to 0, so that they are synchronized in time, so that the sound pressure signal collected by the microphone is more accurate, so as to eliminate the measurement error to the greatest extent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com