Encapsulating method

A packaging method and substrate technology, which can be applied to measurement devices, microstructure devices, and manufacturing microstructure devices, etc., can solve the problems that the quality factor of micromechanical gyroscopes is not high enough and cannot meet technical needs, and can improve device stability and improve Device sensitivity, the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

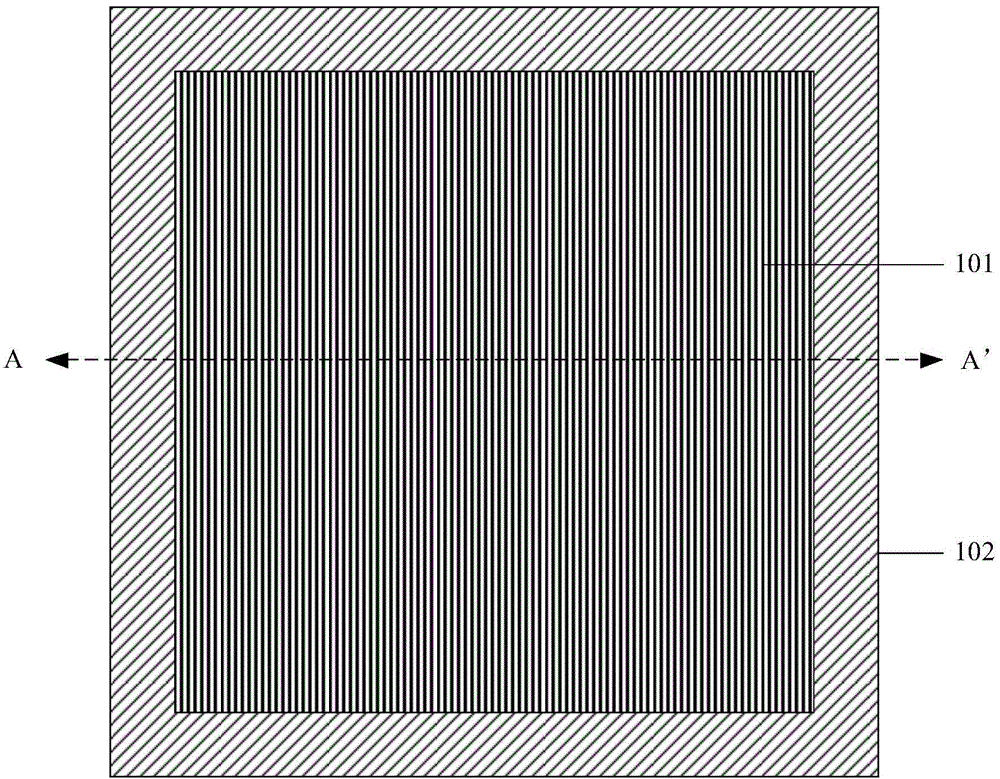

Image

Examples

Embodiment Construction

[0027] As mentioned in the background technology, the quality factor of the micromechanical system in the prior art is not high enough, and the reason for the low quality factor is analyzed now: the micromechanical system usually requires a high-vacuum working environment to reduce the influence of air resistance on the micromechanical device . In other words, the performance of micromechanical systems operating in a high vacuum environment is higher; the lower the air resistance, the higher the quality factor. Therefore, increasing the vacuum degree of the packaging cavity can effectively improve the quality factor of the micro-mechanical system, thereby improving the performance of the micro-mechanical system.

[0028] In order to solve the technical problem, the present invention provides a packaging method, including:

[0029] forming a substrate with micromechanical devices formed therein;

[0030] forming a first patterned metal layer on the surface of the substrate; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com