Camera angle adjustment bracket and camera

An angle adjustment and camera technology, which is applied to the camera body, camera, machine/support, etc., can solve the problems of manual adjustment of camera shooting angle and inability to calibrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

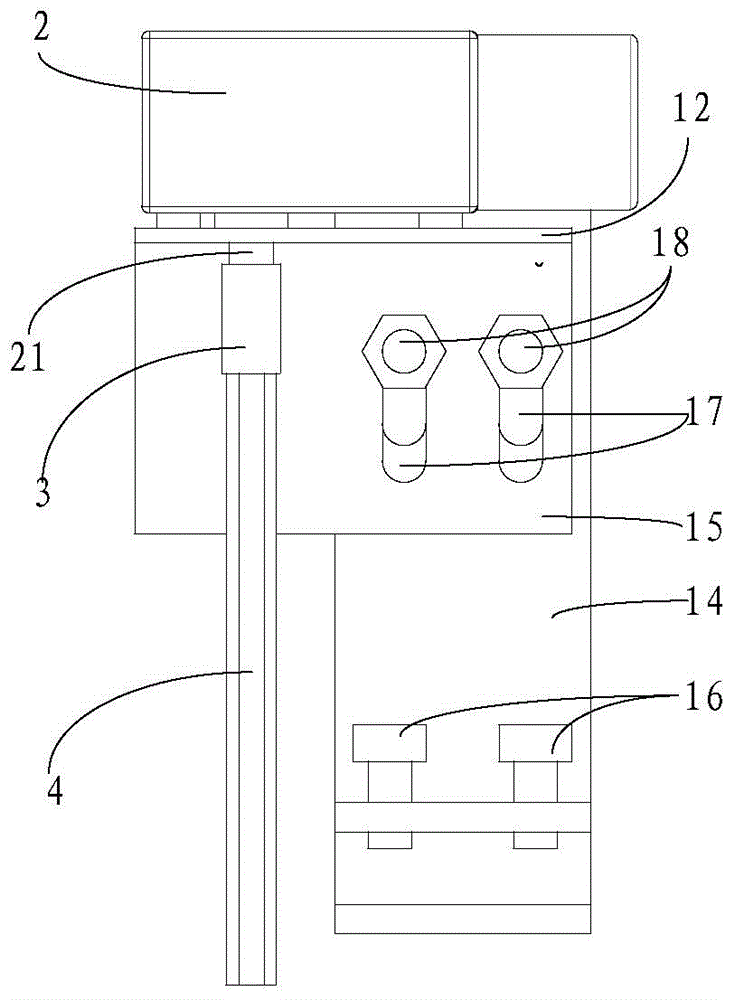

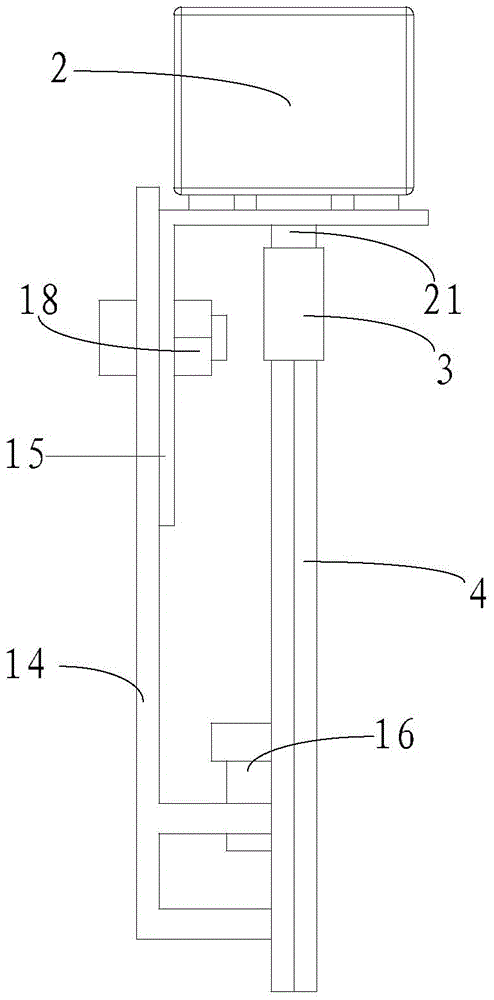

[0044]In this embodiment, a camera angle adjustment frame is provided, and the angle adjustment frame is used to rotate the adjustment bolt on the adjustment bottom plate of the camera to adjust the shooting angle of the camera. Please refer to Figure 1A , Figure 1B , Figure 1C , Figure 1D , Figure 1E , the camera angle adjustment frame includes:

[0045] A support frame 1, one end of the support frame 1 is provided with a fixed structure 11; the other end of the support frame 1 is provided with a support plate 12, and the support plate 1 is provided with a first through hole 13;

[0046] Motor 2, the motor 2 is fixed on the support plate 1; the rotating shaft 21 of the motor 2 passes through the first through hole 13 and is inserted into the connection through hole of the docking handle 3, and is connected with the docking handle 3 fixedly connected; wherein, when the support frame 1 is fixed to the adjustment base plate through the fixing structure 11, the centerline...

Embodiment 2

[0068] A camera is provided in this embodiment, please refer to Image 6 , Image 6 It is a structural schematic diagram of the camera in the embodiment of the present application. The camera includes a base 601, an adjustment bottom plate 603 fixed on the base 601 by N fixing bolts and M adjustment bolts 602, and fixedly placed on the adjustment bottom plate 603. The image acquisition unit 604, N, M are positive integers, and the camera also includes:

[0069] M camera angle adjustment frames 605 connected one by one to the M adjustment bolts, each camera angle adjustment frame in the M camera angle adjustment frames 605 includes:

[0070] A support frame, one end of the support frame is provided with a fixed structure; the other end of the support frame is provided with a support plate, and the support plate is provided with a first through hole;

[0071] A motor, the motor is fixed on the support plate; the rotation shaft of the motor passes through the first through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com