Intermittent drive device for ratchet wheel

A transmission device and ratchet technology, applied in transmission devices, belts/chains/gears, mechanical equipment, etc., can solve the problem of fast pawl wear and achieve the effect of small wear and long working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

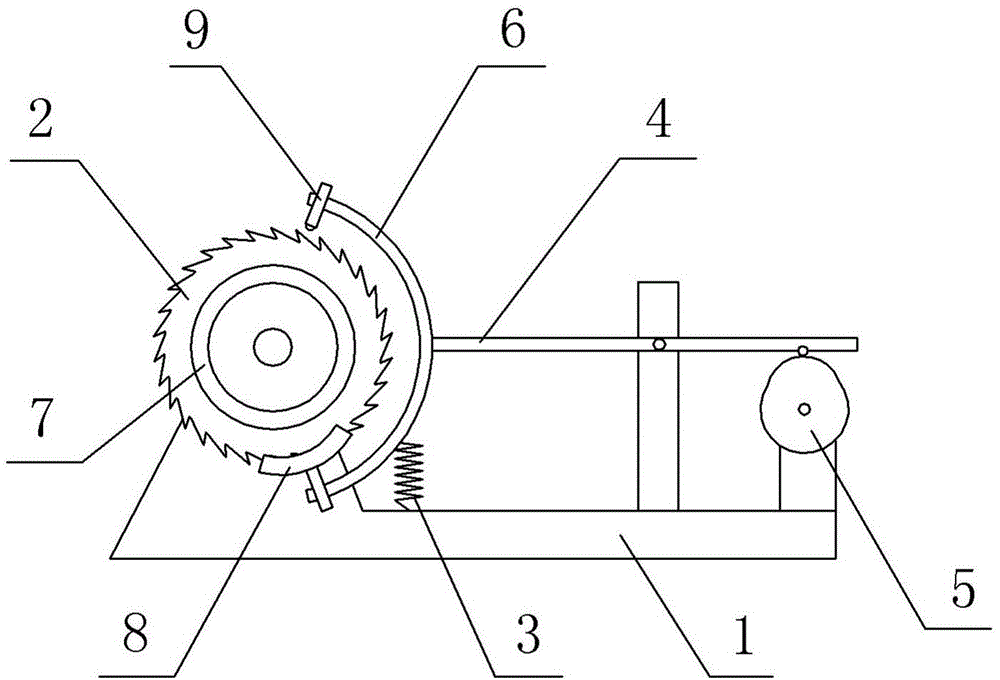

[0015] Such as figure 1 As shown, a ratchet intermittent transmission device in this embodiment includes a frame 1, a ratchet 2, a compression spring 3, a control rod 4 and a cam 5 hinged on the frame 1, and the ratchet 2 is rotatably connected to the frame 1 . One end surface of the cam 5 is provided with a drive ring 7 along the circumference, the drive ring 7 is located at one half of the diameter of the addendum circle of the ratchet 2, the middle part of the control rod 4 is hinged on the frame 1, and the right end of the control rod 4 is against the cam 5 , The right end of the control rod 4 is provided with a roller, and the left end of the control rod 4 is provided with two upper and lower struts 6 . The included angle between the two struts 6 is greater than the angle corresponding to a ratchet on the ratchet 2, wherein the lower strut 6 is provided with a friction plate 8 that can be in contact with the drive ring 7, and the upper strut 6 is provided with a brake pa...

Embodiment 2

[0019] The difference between this embodiment and Embodiment 1 is that the compression spring is replaced by a tension spring, and one end of the tension spring is still connected to the frame 1, but the other end is connected to the position near the right end of the control rod 4, and the purpose is also to make the control The rod 4 and the cam 5 are always in a tight state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com