Heavy dust-proof sliding rail

A slide rail, heavy-duty technology, used in bearings, linear motion bearings, shafts and bearings, etc., can solve problems such as jamming, slide rail deformation, weak carrying capacity of a single slide rail, etc. scrolling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

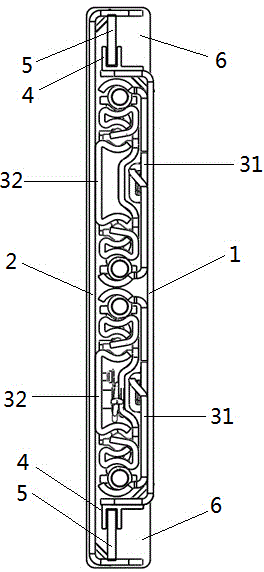

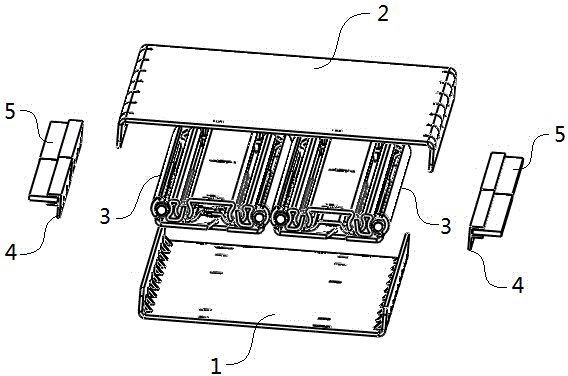

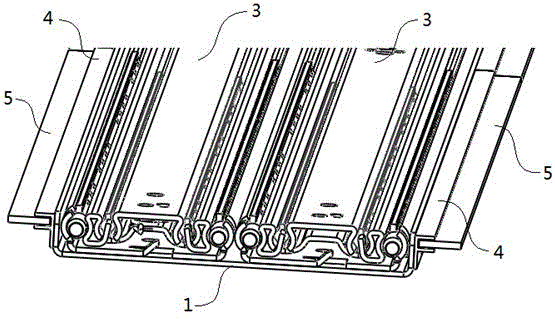

[0019] see Figure 1-3 As shown, a heavy-duty dust-proof slide rail includes an inner connecting plate 1 and an outer connecting plate 2, the outer connecting plate 2 is sleeved outside the inner connecting plate 1, and the inner connecting plate 1 is connected to the outer Two slide rails 3 are arranged side by side between the plates 2, the outer rail 31 of the slide rail 3 is fixed on the inner connecting plate 1, and the inner rail 32 of the sliding rail 3 is fixed on the outer connecting plate 2 , the outer surface of the inner connecting plate 1 is provided with a brush seat 4, the brush seat 4 is provided with a brush 5, and the brush 5 is in contact with the inner surface of the outer connecting plate 2, the The rear end of the external connection plate 2 is provided with a rear cover 6 . The brush 5 can well block larger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com