Compressor start control method

A compressor and timing control technology, applied in pump control, machine/engine, mechanical equipment, etc., can solve problems such as high labor costs and operational errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

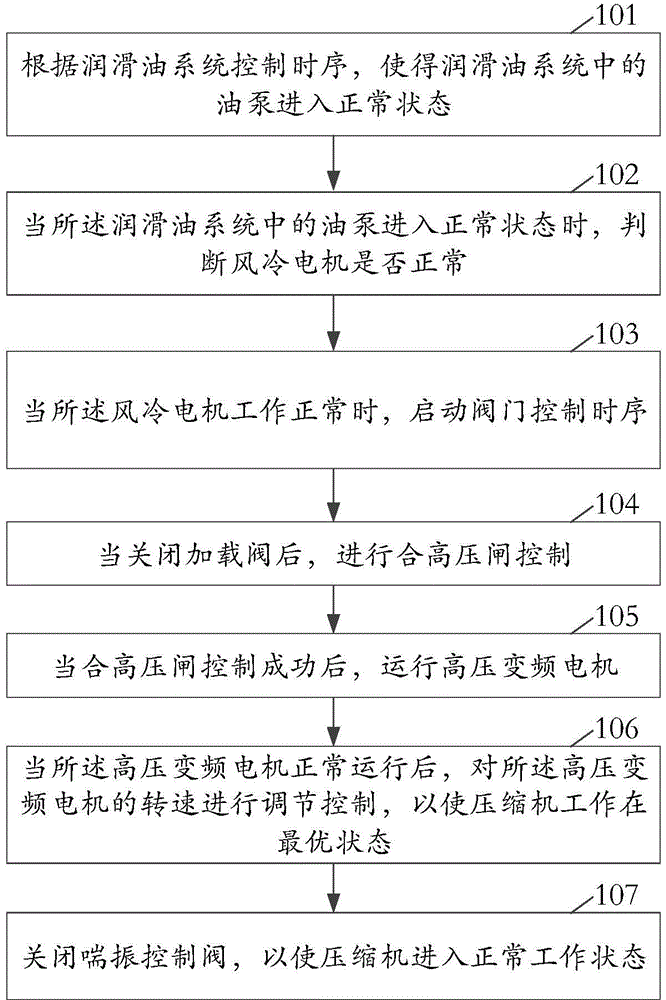

[0043] The embodiment of the present invention combines the control requirements and characteristics of each system unit of the compressor (compressor body, motor unit, dry gas sealing system and electrical system, etc.), sets the control logic of the system, and realizes the control function of one-button safe startup of the compressor , a flow chart of a compressor start-up control method provided by an embodiment of the present invention, as shown in figure 1 shown, including:

[0044] Step 101, making the oil pump in the lubricating oil system enter a normal state according to the control sequence of the lubricating oil system;

[0045] Wherein, the oil pump includes two mutually backup oil pumps and four jacking shaft oil pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com