Remote control system for swivel cementing head

A technology of remote control system and cement head, which is applied in the direction of wellbore/well components, earthwork drilling and production, sealing/isolation, etc. It can solve the problems of low safety and unreasonable structure, and achieve improved operation safety, simple lines, Effect of Reducing Processing Difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

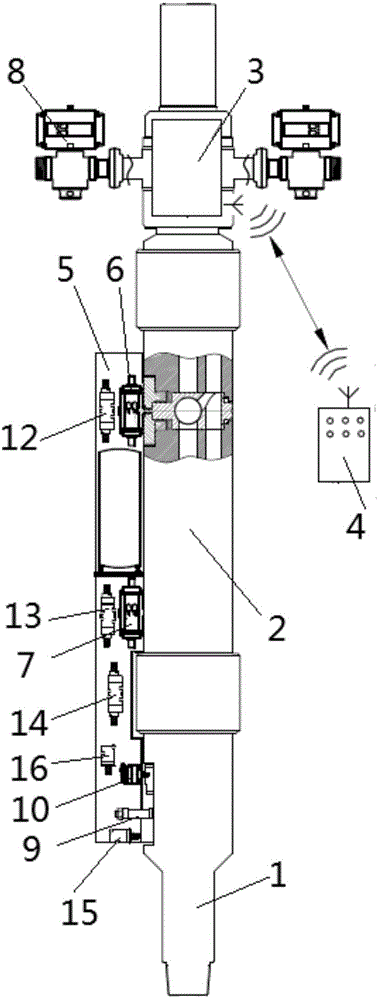

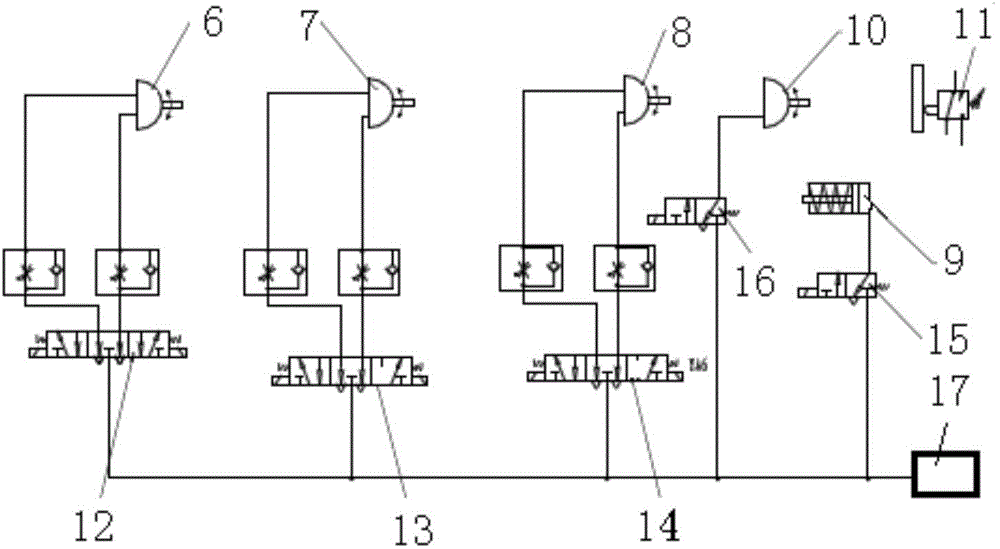

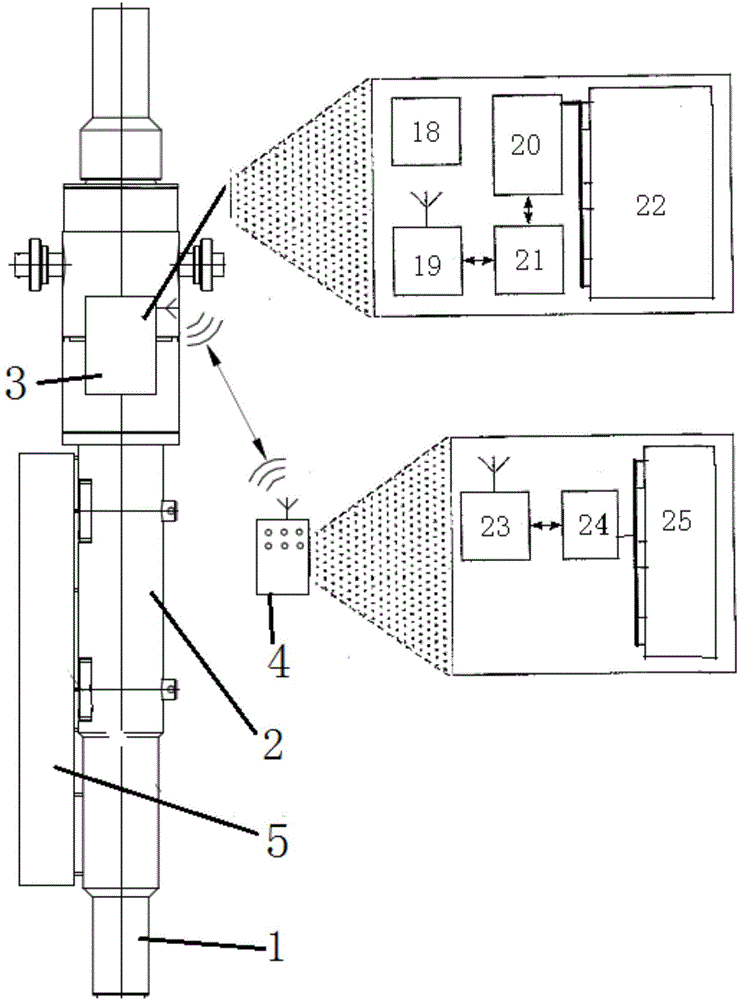

[0017] refer to figure 1 , the structure of the rotary cement head remote control system of the present invention is that it includes three parts: an electric control mechanism 3, a wireless remote controller 4, and an air control mechanism 5, wherein the electric control mechanism 3 and the air control mechanism 5 are arranged on the cement head body 2 of the cement head 1 On the outer surface, the wireless remote controller 4 is set at the operating position of the rear personnel, the wireless remote controller 4 communicates with the electric control mechanism 3 through radio waves, the electric control mechanism 3 communicates with the air control mechanism 5 through cables, and the air control mechanism 5 completes the cement head full function;

[0018] The structure of the electric control mechanism 3 is to include a separate power su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com