Laser leveling machine for terrace

A leveling machine and laser technology, applied in the direction of measuring devices, instruments, measuring instruments, etc., can solve the problem of secondary leveling, achieve the effect of less construction personnel, light weight, and improve the construction level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

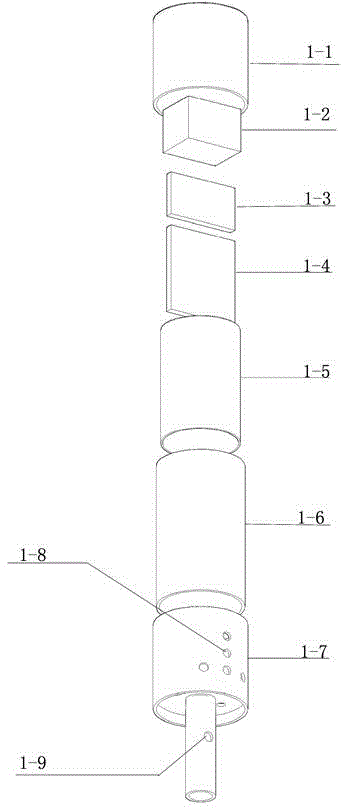

[0030] Depend on figure 1 , 2 Shown: The floor laser leveling machine includes a laser receiving device 1, an adjustable telescopic strut 2 connected between the receiving device 1 and the adjustable vibration scraper 5, and a vibration motor 3 located at the center of the vibration scraper 5. The horizontal sensing device 4 at the middle position of the sliding carriage 7, the adjustable vibrating scraper 5 connected to the sliding carriage 7 through the parallel mechanism 13, the servo motor 6 for adjusting the elevation of the vibrating scraper 5, and the sliding dragging that takes into account the troweling function Plate 7, a chassis 8 with a high-energy battery is arranged on the sliding carriage 7, a control box 9 is arranged at the top of an L-shaped bracket 15, the L-shaped bracket 15 is hinged on the sliding carriage 7, and the control box 9 There is a handle 10 on it, and an adjustable dust baffle 11 is symmetrically arranged on both sides of the adjustable vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com