On-site anti-corrosion treatment method for steel pipe piles for wharves

A technology for anti-corrosion treatment and steel pipe piles, which is used in sheet pile walls, protection devices, buildings, etc., and can solve the problems of unguaranteed scraping and coating quality, scraping and coating quality defects of steel pipe piles, and rapid corrosion of steel pipe piles. , to achieve the effect of reducing labor input, saving transportation costs, and saving materials for repairing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with embodiment.

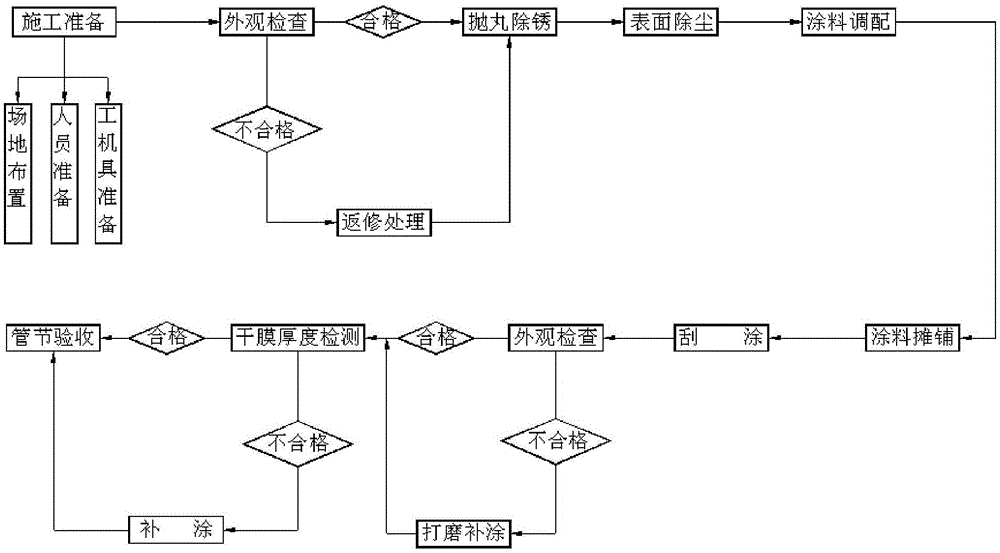

[0032] Such as figure 1 As shown, the on-site anti-corrosion treatment method for steel pipe piles for wharves is specifically carried out according to the following steps:

[0033] I. Construction preparation

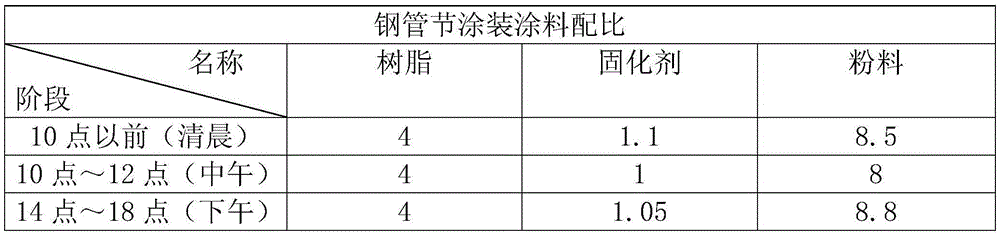

[0034] According to the on-site environmental and climate conditions and design requirements, the on-site coating site is arranged, including the division of various areas (shot blasting machine installation, coating area, semi-finished product, finished product area and paint mixing area), manpower, equipment and tools, dry film The configuration of thickness and adhesion testing instruments, as well as the configuration of temperature and humidity meters;

[0035] II. Visual inspection of steel pipe joints

[0036] Check the steel pipe joints, including the roundness of the steel pipe joint ports, the appearance and internal quality of the weld, and the qualified ones wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com