A three-in-one anchor cable construction device for hole forming, installation and grouting

A construction device and three-in-one technology, which are applied in basic structure engineering, drilling equipment and methods, sheet pile walls, etc., can solve the problem that the drill pipe cannot be attached to the anchor cable, etc., and achieve high construction reliability, strong adaptability, Material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in combination with two specific embodiments.

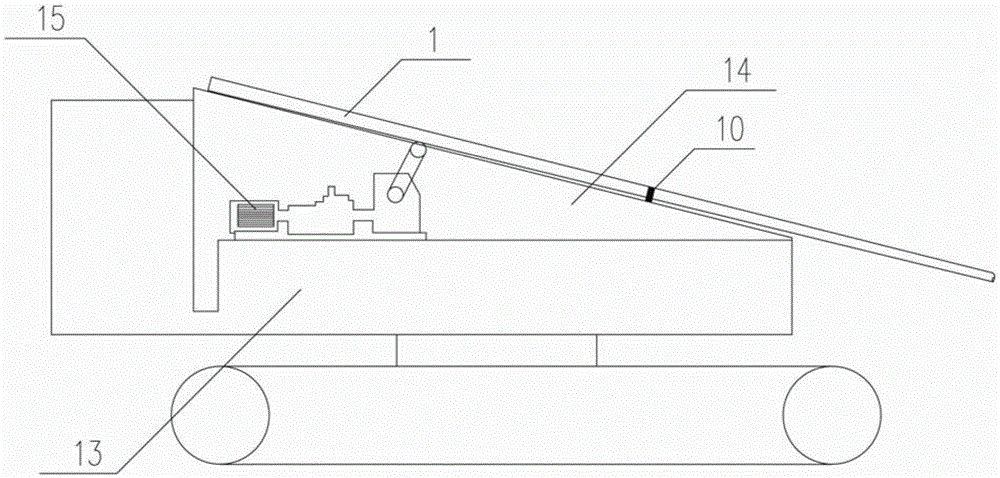

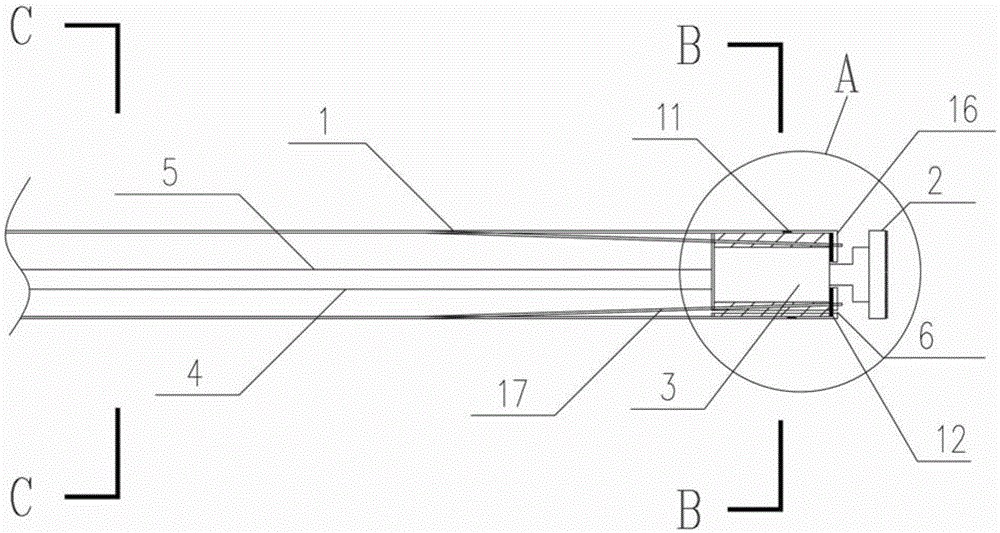

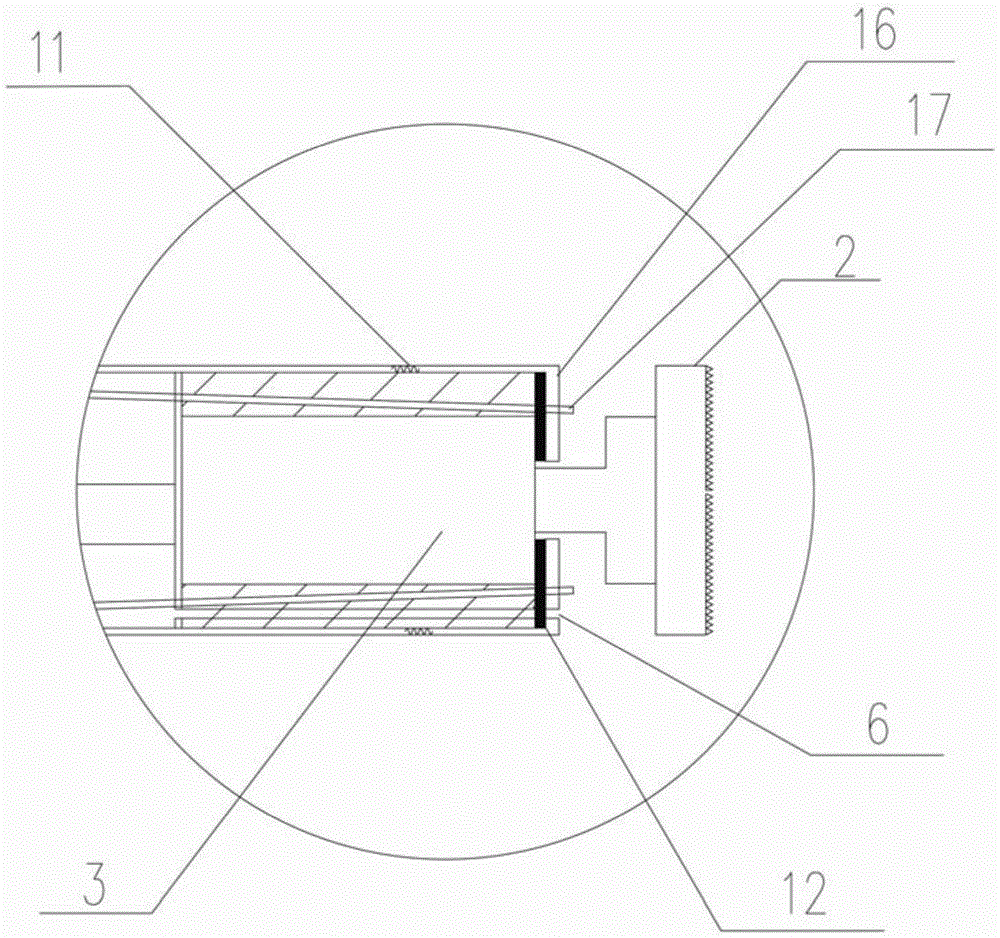

[0034] Such as figure 1 As shown, the three-in-one anchor cable construction device of hole forming, installation, and grouting described in this embodiment includes an anchor cable disconnector 10, a crawler loader 13, a drill pipe assembly and disassembly platform 14, a drill pipe assembly and A push-pull power system 15 that provides push and pull forces for the drill pipe assembly to realize its drilling advancement and withdrawal, wherein the drill pipe assembly and disassembly platform 14 and the push-pull power system 15 are respectively installed on the crawler loader 13 , the push-pull power system 15 is located below the drill pipe assembly and disassembly platform 14, and it is connected with the drill pipe 1 of the drill pipe assembly placed on the drill pipe assembly and disassembly platform 14 through a transmission mechanism, and the drill pipe assembly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com