Purification method of dodecanedioic acid

A technology for crude dodecanedioic acid and dodecanedioic acid, which is applied in the field of purification of dodecanedioic acid, and can solve the problems of reducing the yield of dodecanedioic acid, volatilization of acetic acid and methanol, and increasing the load of purification, etc. Problems, to achieve the effect of environmental protection, improve purity, reduce the generation of salt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

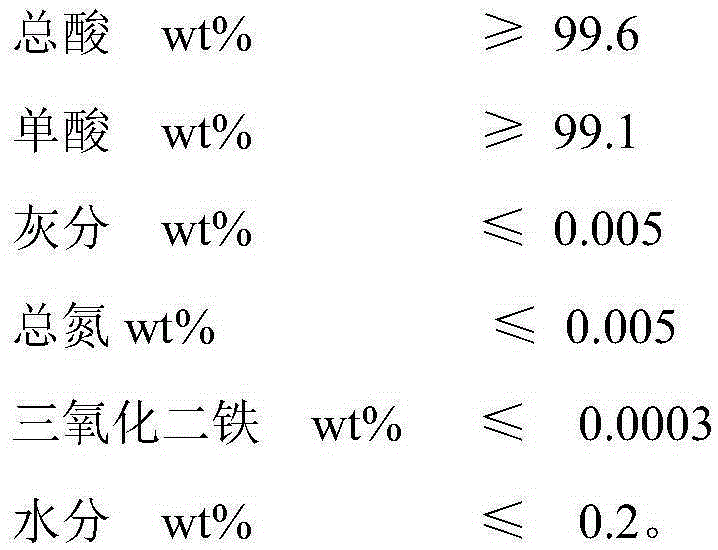

Embodiment 1

[0064] A kind of refining method of improving dodecanedioic acid purity and yield of the present invention comprises the following steps:

[0065] ①.. Adsorption decolorization

[0066] In the dissolution reactor, put 1000 parts by weight of deionized water, add 180 parts by weight of crude dodecanedioic acid in dry weight under stirring, add 110 parts by weight of sodium hydroxide aqueous solution with a mass concentration of 30.3%, and heat up to 100 °C , the pH value is controlled between 6.0, after the material is completely dissolved, add 3 parts by weight of coconut shell-type activated carbon, and keep warm for 20 minutes for decolorization;

[0067] ②..oxidative decolorization

[0068] Filter the material treated in step ① while it is hot, rinse the filter cake with hot water at 90°C, put the filtrate and flushing liquid into the oxidation decolorization reaction kettle, raise the temperature to 98°C, and control it at 5~ Within 10 minutes, add hydrogen peroxide with...

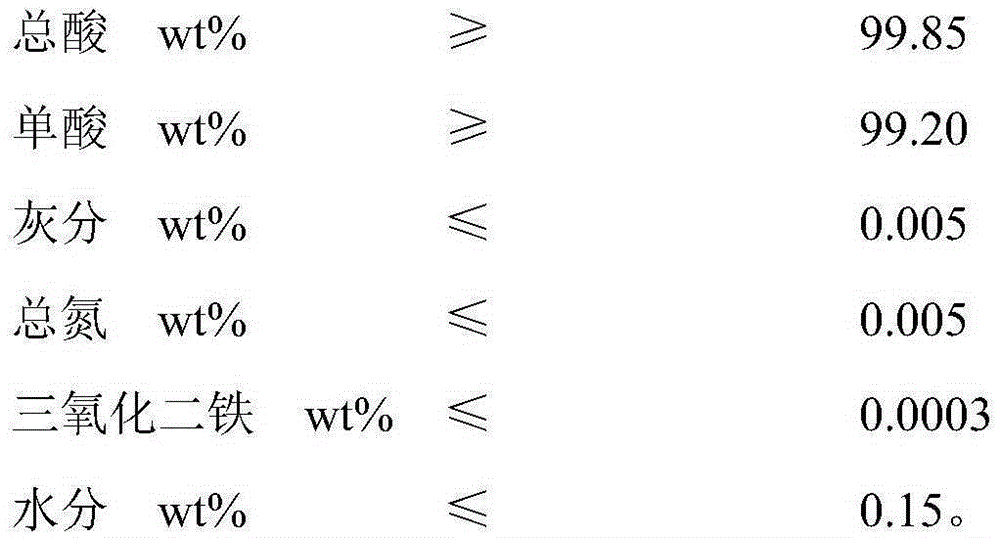

Embodiment 2

[0079] A kind of refining method of improving dodecanedioic acid purity and yield of the present invention comprises the following steps:

[0080] ①.. Adsorption decolorization

[0081] In the dissolution reactor, put 1000 parts by weight of deionized water, add 180 parts by weight of crude dodecanedioic acid in dry weight under stirring, add 110 parts by weight of sodium hydroxide aqueous solution with a mass concentration of 30.3%, and heat up to 101 ° C , the pH value is controlled between 6.1, after the material is completely dissolved, add 4 parts by weight of coconut shell-type activated carbon, and keep warm for 30 minutes for decolorization;

[0082] ②..oxidative decolorization

[0083] Filter the material treated in step ① while it is hot, rinse the filter cake with hot water at 85°C, put the filtrate and flushing liquid into the oxidation decolorization reaction kettle, raise the temperature to 99°C, and control it at 5~ Within 10 minutes, add hydrogen peroxide wit...

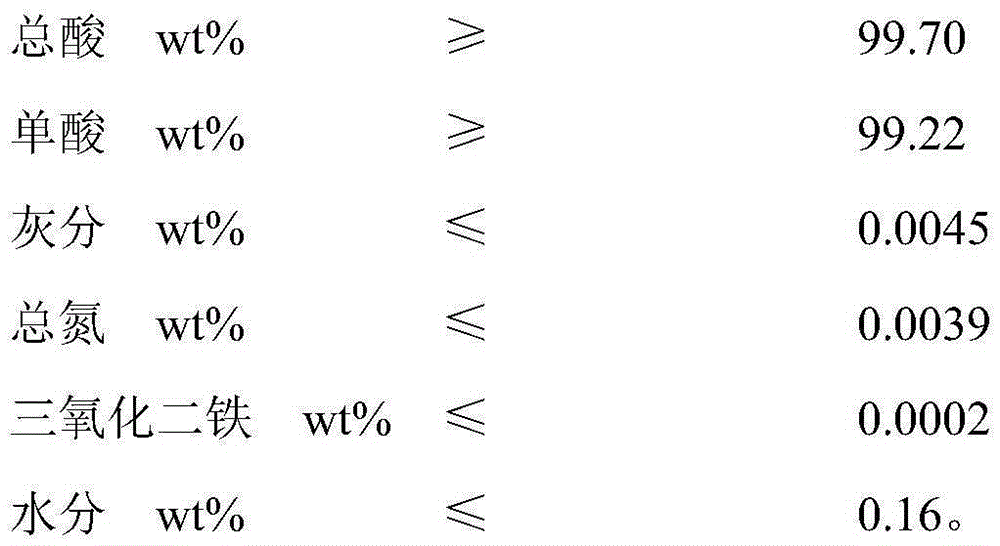

Embodiment 3

[0094] A kind of refining method of improving dodecanedioic acid purity and yield of the present invention comprises the following steps:

[0095] ①.. Adsorption decolorization

[0096] In the dissolution reactor, put 1000 parts by weight of deionized water, add 180 parts by weight of crude dodecanedioic acid in dry weight under stirring, add 110 parts by weight of sodium hydroxide aqueous solution with a mass concentration of 30.3%, and heat up to 102 ° C , the pH value is controlled between 6.2, after the material is completely dissolved, add 5 parts by weight of coconut shell-type activated carbon, and keep warm for 25 minutes for decolorization;

[0097] ②..oxidative decolorization

[0098] Filter the material treated in step ① while it is hot, rinse the filter cake with hot water at 88°C, put the filtrate and flushing liquid into the oxidation decolorization reaction kettle, raise the temperature to 100°C, and control the temperature at 5~ Within 10 minutes, add hydroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com