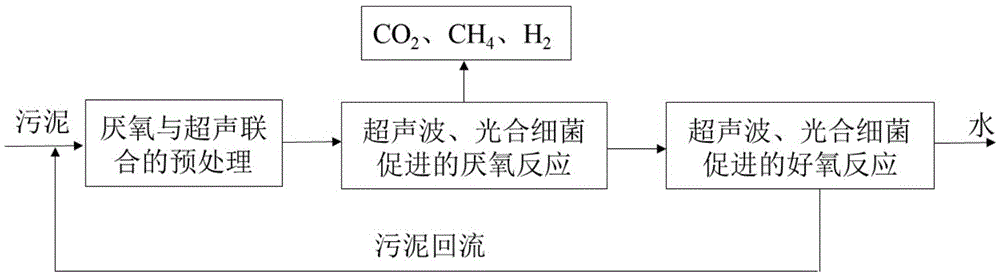

A method of combining ultrasonic waves and photosynthetic bacteria to promote the digestion of excess sludge

A technology of photosynthetic bacteria and excess sludge, applied in chemical instruments and methods, sludge treatment, biological sludge treatment, etc., can solve the problems of environmental secondary pollution, achieve high reduction efficiency, high degree of cracking, and degradation full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Combined pretreatment of anaerobic bacteria and ultrasound

[0038] Input 4L of excess sludge with a concentration of 8000mg / L into a 5L anaerobic reactor, a large number of aerobic microorganisms in the excess sludge will die and dissolve under anaerobic conditions, and use the anaerobic microorganisms and facultative The microorganisms perform anaerobic digestion on the remaining sludge at room temperature. After 48 hours of anaerobic digestion, the remaining sludge after anaerobic digestion is input into an ultrasonic processor for ultrasonic treatment for 30-60 minutes. The ultrasonic frequency of the ultrasonic processor is 20kHz. Density 15W / cm 2 ;

[0039]2) Anaerobic digestion promoted by ultrasound and photosynthetic bacteria

[0040] In step 1), the sludge after ultrasonic treatment is input into the 28L anaerobic reactor containing EM bacteria for water purification, and the concentration of photosynthetic bacteria in the bacterium liquid of EM bacteria ...

Embodiment 2

[0047] After the surplus sludge of embodiment 1 completes the entire digestion process, according to the same steps and parameters as in embodiment 1, new surplus sludge and the unfiltered liquid slurry processed in step 3) are input to step 1 of embodiment 1 ) the input speed of the anaerobic reactor is controlled at 2L / d, and the output speed is also 2L / d, so that the residence time in the anaerobic reactor of step 1) is 48h; the sludge input after step 1) treatment To step 2) the input speed of the anaerobic reactor is controlled at 2L / d, and the output speed of the anaerobic fermentation broth is 5L / d, so that its residence time in the anaerobic reactor of step 2) is 5d; The input speed of the reaction tank of input step 3) is controlled at 5L / d, and the output speed is about 12.5L / d, so that the residence time in the reaction tank described in step 3 is 36h.

[0048] The process has a digestibility rate of 52.8% for the remaining sludge.

Embodiment 3

[0050] 1) Combined pretreatment of anaerobic bacteria and ultrasound

[0051] Input 9L of excess sludge with a concentration of 10000mg / L into a 10L anaerobic reactor, and a large number of aerobic microorganisms in the excess sludge will die and dissolve under anaerobic conditions, and at a stirring speed of 500-800rpm, use The anaerobic microorganisms and facultative microorganisms in the sludge anaerobically digest the remaining sludge at room temperature for 72 hours. During the digestion period, the remaining sludge after anaerobic digestion is input into an ultrasonic processor for ultrasonic treatment for 30-60 minutes. Ultrasonic frequency 28kHz, ultrasonic density 20W / cm 2 ;

[0052] 2) Anaerobic digestion promoted by ultrasound and photosynthetic bacteria

[0053] The sludge after ultrasonic treatment was input into a 75L anaerobic reactor containing EM bacteria for water purification, and the concentration of photosynthetic bacteria in the bacterial solution of EM...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com