A kind of method for synthesizing manganese vanadate nanometer material

A technology for synthesizing nanometer and nanometer manganese vanadate, which is applied in the directions of nanotechnology, nanotechnology, chemical instruments and methods to achieve the effects of low temperature controllable preparation, controllable conditions and pure product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

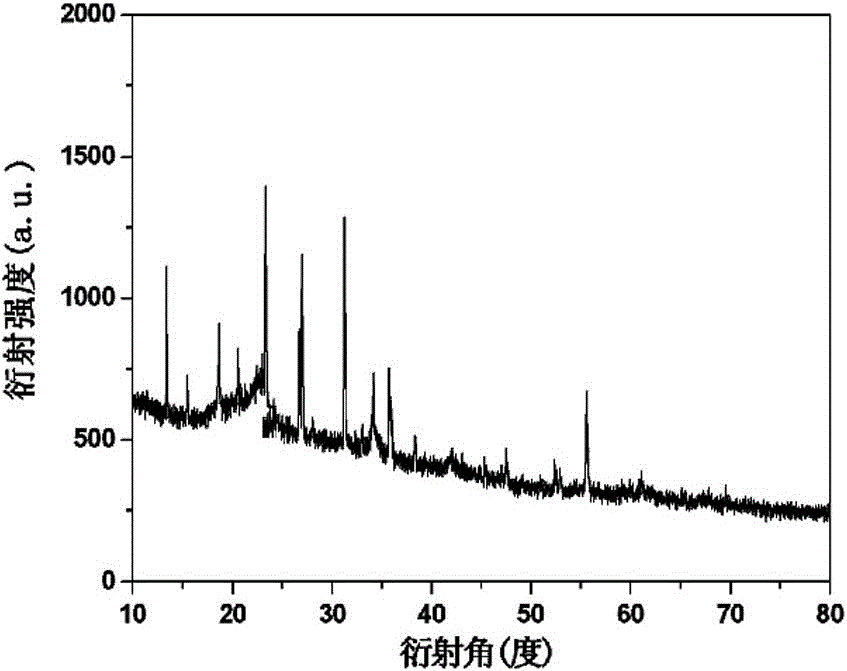

[0022] At room temperature, 2 mmol of sodium orthovanadate was dissolved in 6 mL of distilled water, and 1 mmol of MnSO 4 ·H 2 O was dissolved in 8 mL distilled water, and the sodium orthovanadate solution was added dropwise to the MnSO 4 solution, stirred for 10 min, with 1mol / L H 2 SO 4 The solution adjusted the pH value of the reaction system to 7, continued to stir for 10 min, then transferred it into a 20 mL hydrothermal reaction kettle, sealed it and placed it in a constant temperature box for 6 hours of hydrothermal reaction at 160 °C, and cooled to room temperature after the reaction , washed three times with deionized water and absolute ethanol respectively, centrifuged, and placed the resulting precipitate in an oven at 60 °C for 16 hours in vacuum to obtain manganese vanadate Mn 6.87 (OH) 3 (VO 4 ) 3.6 (V 2 o 7 ) 0.2 Material. The above product was analyzed by X-ray diffraction (XRD) and scanning electron microscope, and the results were as follows: figur...

Embodiment 2

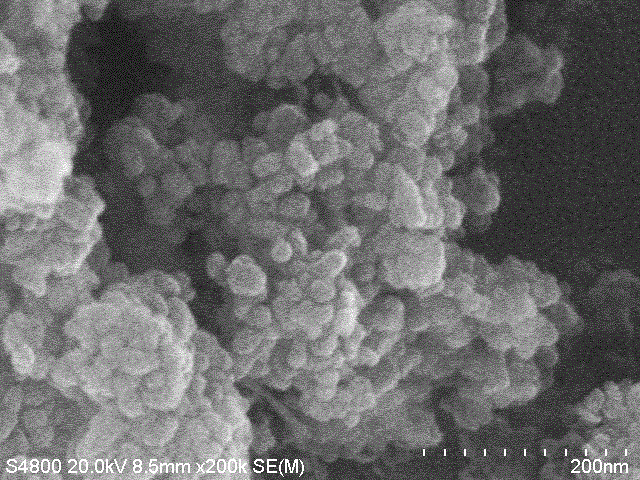

[0024] At room temperature, 0.2 mmol of sodium orthovanadate was dissolved in 6 mL of distilled water, and 0.1 mmol of MnCl 2 Dissolved in 8mL distilled water, under the action of magnetic stirring, the sodium orthovanadate solution was added dropwise to the MnCl 2 solution, stirred for 10 min, adjusted the pH value of the reaction system to 8 with 1mol / L HCl solution, continued to stir for 10 min, then transferred to a 20 mL hydrothermal reactor, sealed and placed in a constant temperature box Hydrothermal reaction at 180 °C for 4 hours, after the reaction was completed, cool to room temperature, wash with deionized water and absolute ethanol for 5 times, centrifuge, and place the resulting precipitate in an oven for 8 hours at 80 °C to obtain manganese vanadate Mn 6.87 (OH) 3 (VO 4 ) 3.6 (V 2 o 7 ) 0.2 The nanoparticle material is a spherical particle with a diameter of 30-60nm.

Embodiment 3

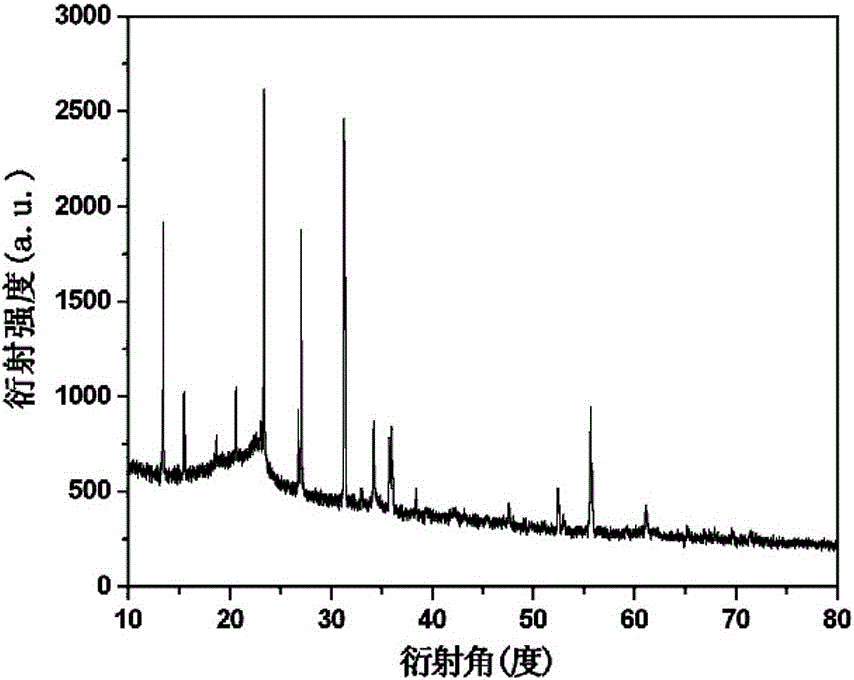

[0026] At room temperature, 2 mmol of sodium orthovanadate was dissolved in 6 mL of distilled water, and 2 mmol of MnCl 2 Dissolved in 8mL distilled water, under magnetic stirring, the sodium orthovanadate solution was added dropwise to the MnCl 2 solution, stirred for 10 min, with 1mol / L HNO 3 The solution adjusted the pH value of the reaction system to 8 and continued to stir for 10 min, then transferred it into a 20 mL hydrothermal reaction kettle, sealed it, and placed it in a thermostat for 22 h at 180 °C for hydrothermal reaction. After the reaction was completed, it was cooled to At room temperature, wash five times with deionized water and absolute ethanol respectively, centrifuge, and place the obtained precipitate in an oven at 80°C for 8 hours in vacuum to obtain manganese vanadate Mn 6.87 (OH) 3 (VO 4 ) 3.6 (V 2 o 7 ) 0.2 Material. The above product was analyzed by XRD analysis and scanning electron microscope, and the results were as follows: image 3 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com