Desalting and reusing method of high-salinity heavy ash mother liquor in combined-soda system

A technology of high-salt heavy ash mother liquor and heavy ash, which is applied to alkali metal carbonates, chemical instruments and methods, alkali metal compounds, etc., can solve the problems of mother liquor expansion in the system and affect product quality, so as to reduce the expansion of mother liquor and reduce the The effect of accumulating and reducing calcium content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

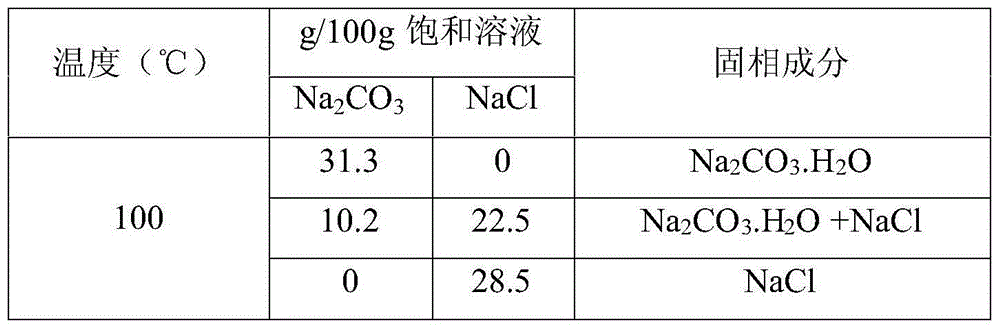

Embodiment 1

[0020] The content of sodium chloride in the heavy ash mother liquor is 60g / L, and the effluent heavy ash mother liquor (sodium carbonate content is 310g / L) enters the evaporation device to evaporate, and the evaporation of the solution reaches carbonic acid when it is about 79% of the total solution mass. The co-saturation point of sodium and sodium chloride causes sodium carbonate monohydrate crystals to separate out, and liquid-solid separation is carried out. The obtained crystals are dissolved in desalinated water to obtain a solution with a sodium chloride content of about 7.8g / L, and the solution is returned to heavy The ash system is reused; the remaining high-salt heavy ash mother liquor after evaporation is used for the salt washing process in the vacuum salt production.

[0021] After testing, the content of sodium carbonate in the low-salt heavy ash mother liquor recycled to the heavy ash system after treatment is about 307g / L, and the content of sodium chloride is ...

Embodiment 2

[0023] Sodium chloride content is 80g / L in the heavy ash mother liquor, the heavy ash mother liquor (sodium carbonate content is 310g / L) of effluent liquid is sent into evaporating device and evaporates, and the evaporation of solution reaches when about 72% of total solution mass. The co-saturation point of sodium carbonate and sodium chloride causes sodium carbonate monohydrate crystals to separate out, and liquid-solid separation is carried out, and the crystal obtained is dissolved in desalinated water to obtain a solution with a sodium chloride content of about 8.3g / L, and the solution is returned to The heavy ash system is reused, and the remaining high-salt heavy ash mother liquor after evaporation is used for the salt washing process in the vacuum salt making process.

[0024] After testing, the content of sodium carbonate in the low-salt heavy ash mother liquor recycled to the heavy ash system after treatment is about 312g / L, and the content of sodium chloride is about...

Embodiment 3

[0026] The content of sodium chloride in the heavy ash mother liquor is 100g / L, and the heavy ash mother liquor (sodium carbonate content is 310g / L) of the effluent liquid is sent to the evaporator for evaporation, and the evaporation of the solution is about 66% of the total mass of the solution. The co-saturation point of sodium carbonate and sodium chloride causes sodium carbonate monohydrate crystals to separate out, and liquid-solid separation is carried out, and the crystal obtained is dissolved in demineralized water to obtain a solution with a sodium chloride content of about 8.9g / L, and the solution is returned to The heavy ash system is reused, and the remaining high-salt heavy ash mother liquor after evaporation is used for the salt washing process in the vacuum salt making process.

[0027] After testing, the content of sodium carbonate in the low-salt heavy ash mother liquor recycled to the heavy ash system after treatment is about 314g / L, and the content of sodium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com