Micro-vacuum automatic balance filling machine and filling method

An automatic balancing and filling machine technology, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of unfavorable sauce industry transformation, high vacuum requirements, high investment costs, etc., to ensure quality and flavor, one time High utilization rate and wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

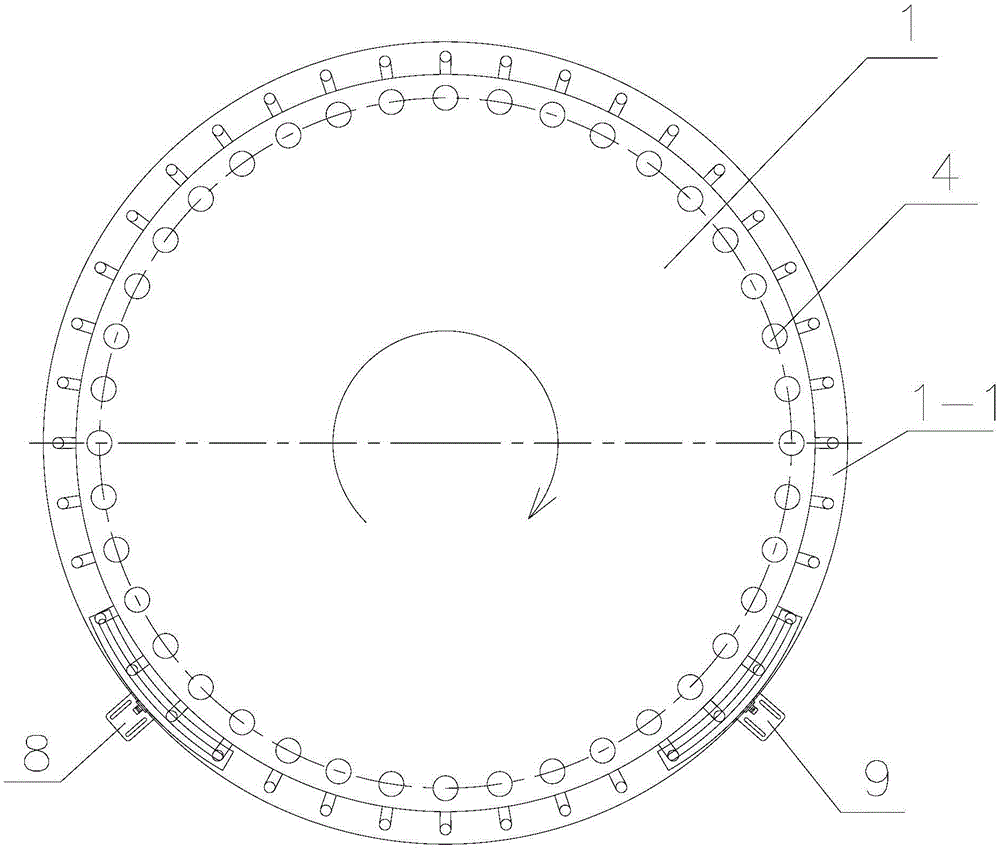

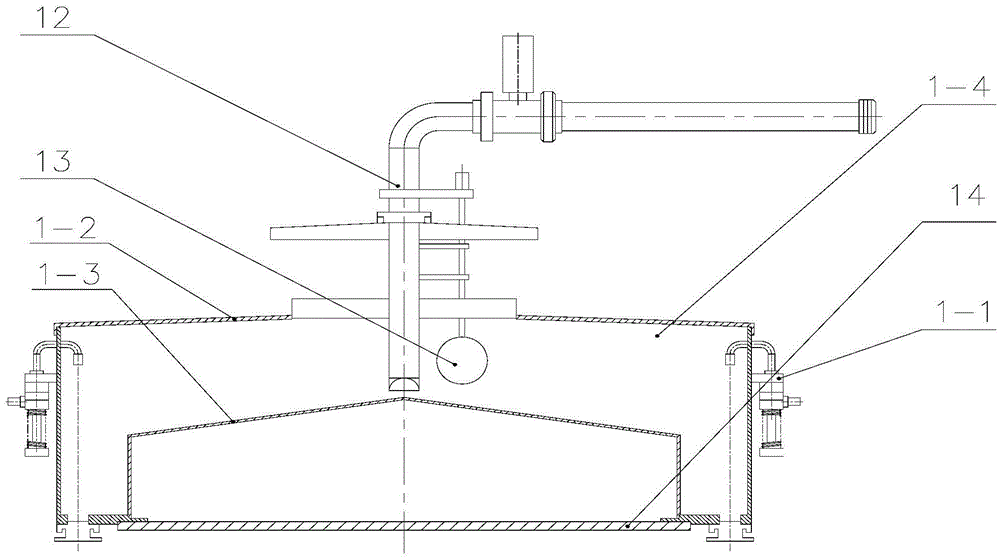

[0038] A kind of micro-vacuum automatic balance type filling machine of present embodiment, as figure 1 As shown, it includes material tank 1, frame 2, turntable assembly 3 and 40 filling valves 4 (the number of filling valves can be flexibly adjusted according to the actual needs of the filling process, generally 20 to 50), 40 The filling valve is distributed at the bottom of the material tank, the turntable assembly is located below the filling valve, and the turntable assembly is set on the frame. There are a number of bottle holding positions corresponding to the filling valves on the turntable assembly. The bottle holder cylinder 5 used to drive the packaging bottle to move up and down is also equipped with a vacuum system on the filling machine. The vacuum system includes a vacuum pump, a negative pressure buffer tank, a vacuum vacuum silicone tube 6 and a vacuum suction cup assembly 7. The side wall of the material cylinder is distributed with A plurality of vacuumed si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com