Tray type automatic packing production line for vegetable plastic wrap

A technology of automatic packaging and fresh-keeping packaging, applied in packaging, transportation packaging, packaged food, etc., can solve problems such as unfavorable equipment promotion, increase in equipment price, increase manufacturing cost, etc., and achieve labor cost saving, labor saving, and high work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the drawings.

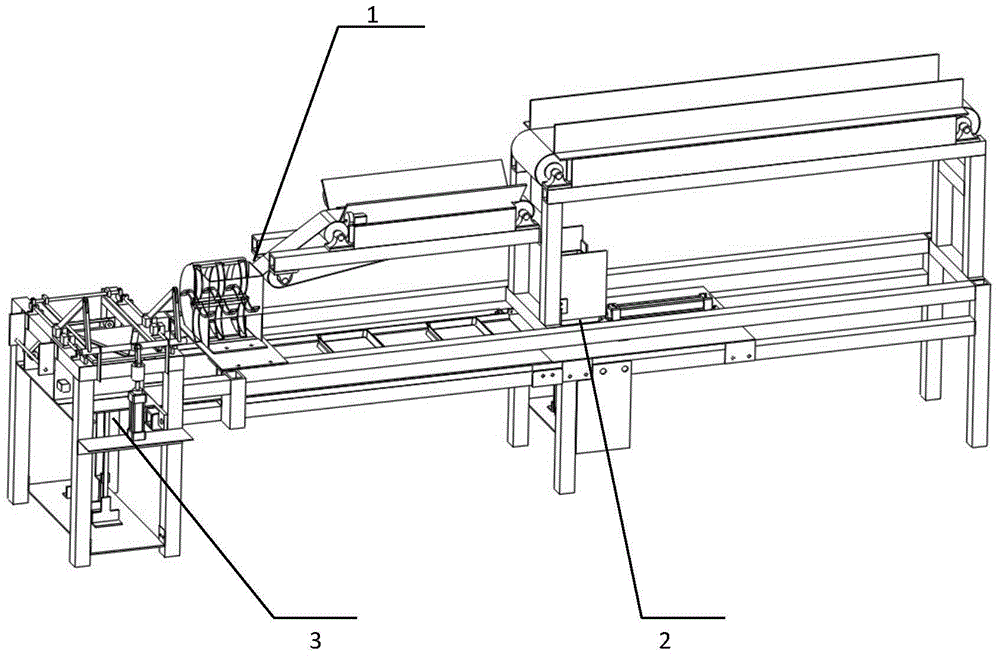

[0037] Such as figure 1 As shown, the production line includes a vegetable positioning device 1, a tray taking-out device 2, a fresh-keeping packaging device 3. When the vegetables are harvested, the vegetable aligning device 1 adjusts the vegetables to a state where the long edges of the vegetables are placed along the direction of movement of the vegetable aligning belt, and completes the positioning of the adjusted vegetables into the tray. The tray extracting device 2 extracts and transports the trays to the bottom of the vegetable aligning device to receive vegetables, and transports the trays containing the vegetables to the fresh-keeping packaging device 3. Finally, the fresh-keeping packaging device 3 completes the fresh-keeping film packaging of vegetables and trays.

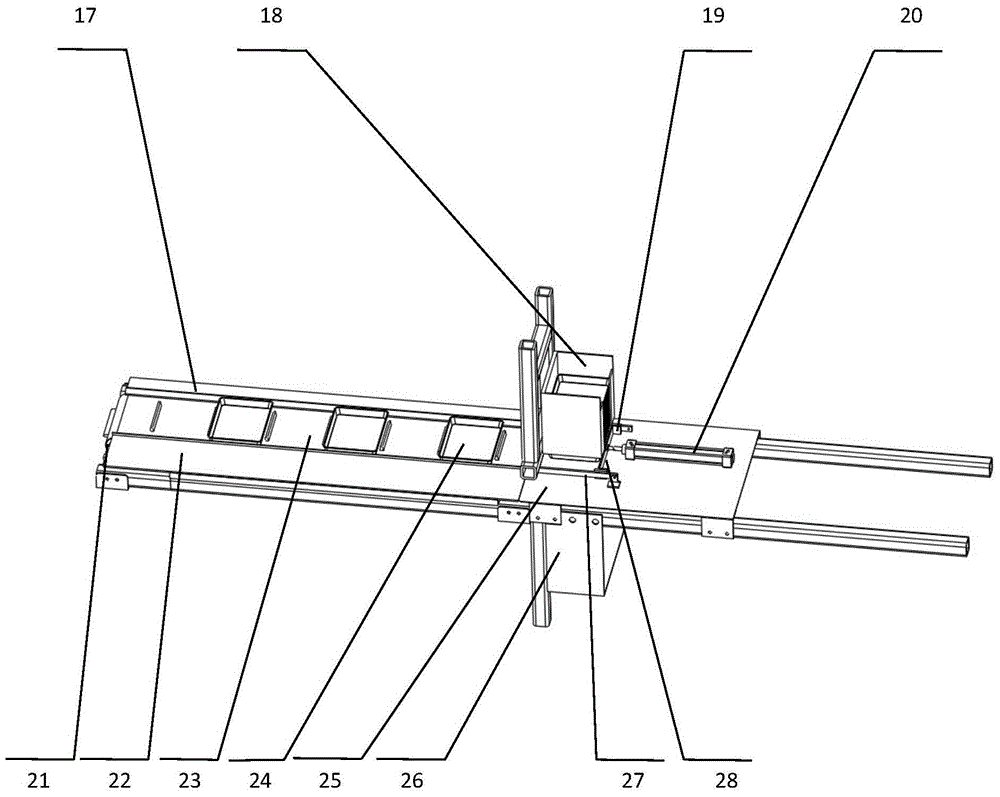

[0038] Such as figure 2 As shown, the harvest belt roller 8 is installed on the frame 16, the vegetable harv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com