Water ballast tank anti-sediment structure

A ballast water tank and anti-siltation technology, which is applied to some tanks in the hull, cleaning equipment for ship tanks, oil tankers, etc., can solve problems such as damage, increase the weight of the ship, corrosion, etc. Labor cost, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

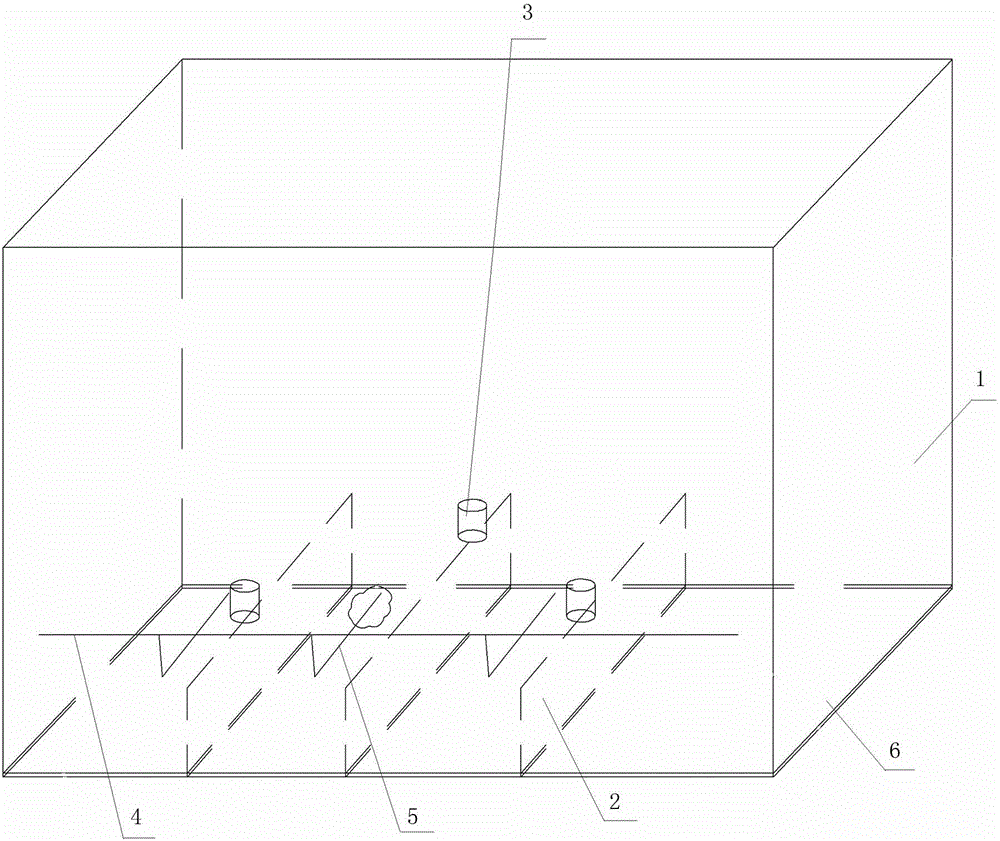

[0008] A ballast tank anti-sedimentation structure, such as figure 1 As shown, there are aggregates 2 arranged at intervals at the bottom of the ballast water tank 1, and a plurality of silt turbulence devices for repeatedly disturbing and crushing silted and precipitated impurities are installed at intervals above the aggregates 2 in the ballast water tank 1.

[0009] The mud turbulence device used for repeatedly disturbing and breaking up silted and precipitated impurities is a cavitation generator, and the cavitation generator is connected with the power control equipment outside the ballast water tank 1 . When it is necessary to clean the precipitated impurities on the bottom of the ballast tank, the side wall and the surface of the aggregate 2, the power control equipment intermittently controls the cavitation generator to emit cavitation, and the cavitation rapidly floats up in the water and produces supercavitation. When each supercavitation breaks, it will produce a ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com