Novel car trunk cover plate and preparation method thereof

A technology for trunk lids and automobiles, applied in chemical instruments and methods, vehicle parts, lamination, etc., can solve the problems of heavy product weight, unrecyclable materials, unsatisfactory odor, etc., and achieve lightweight improvement and complete environmental protection of materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1 Car trunk cover

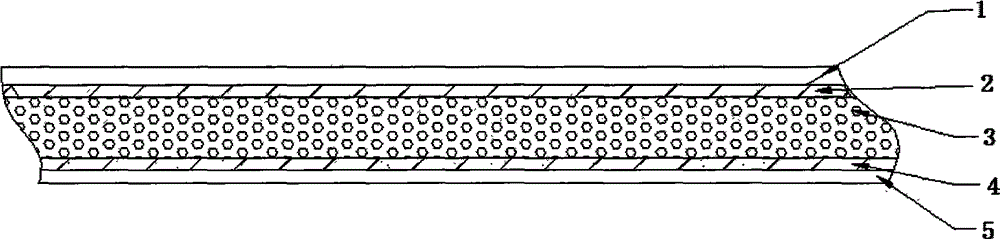

[0015] A new type of automobile trunk cover, comprising an EPP foam layer 3, the surface of the EPP foam layer 3 is compounded with the first hot-melt adhesive film layer 2, and the back is compounded with the second hot-melt adhesive film layer 4; the first hot-melt adhesive The film layer 2 covers the surface decoration layer 1 outside; the second hot melt adhesive film layer 4 covers the bottom surface decoration layer 5 outside. The surface decoration layer 1 is non-woven fabric, and the bottom surface decoration layer 5 is spunlace fabric. The first hot-melt adhesive film layer 2 and the second hot-melt adhesive film layer 4 are hot-melt adhesive film layers reinforced by long glass fibers. The thickness of the EPP foam layer is 15mm. The total thickness of the trunk lid is 20mm.

Embodiment 2

[0016] The preparation method of embodiment 2 automobile trunk lid

[0017] The formed EPP foam sheet is thrown away, and the two layers of hot melt adhesive film are heated to 180°C on the front and back sides respectively. After heating for 1 minute, one layer of hot melt adhesive film, EPP foam sheet and surface decoration layer Composite; Another layer of hot melt adhesive film is composited with EPP foam sheet and bottom decorative layer; the periphery is edge-wrapped.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com