A control method for a fully automatic flame brazing machine

A technology of flame brazing and control method, which is applied in manufacturing tools, welding equipment, electric heating devices, etc., can solve the problems of high scrap rate and difficult flame temperature control, and achieve the effect of reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

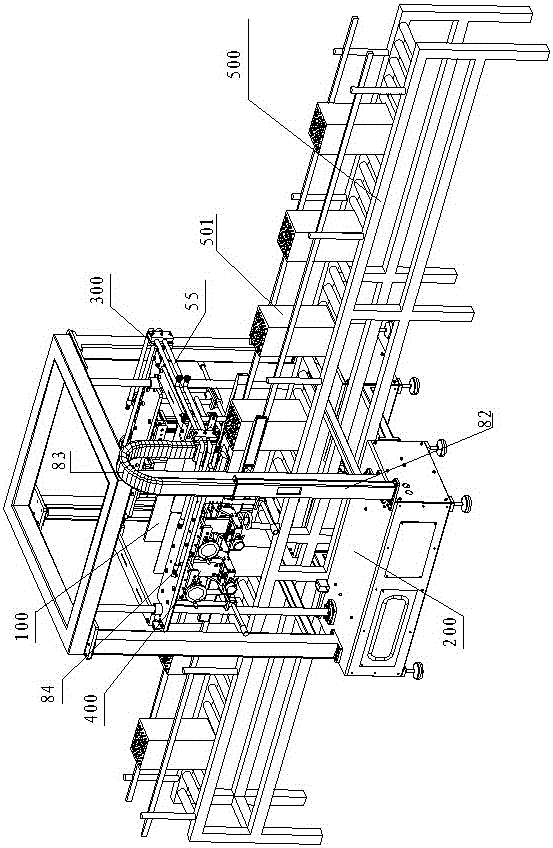

[0063] see figure 1 , the present embodiment includes a lifting device 200, a flame spraying workbench 300, a flame spraying device 400, a flame spraying device 100 and a delivery device 500, the fire spraying workbench 300 is installed on the lifting device 200, and the flame spraying device 400 is installed on the flame spraying On the workbench 300 , the flamethrower 100 is installed on the flamethrower adjusting device 400 , the conveying device 500 passes through the lifting device 200 , and the middle part of the conveying device 500 is located under the flamethrowing workbench 300 . The lifting device 200 controls the lifting of the flame-spraying workbench 300 , the flame-thrower adjusting device 400 controls the flame-spraying direction of the flamethrower 100 , and the flamethrower 100 welds the workpiece 501 on the conveying device 500 .

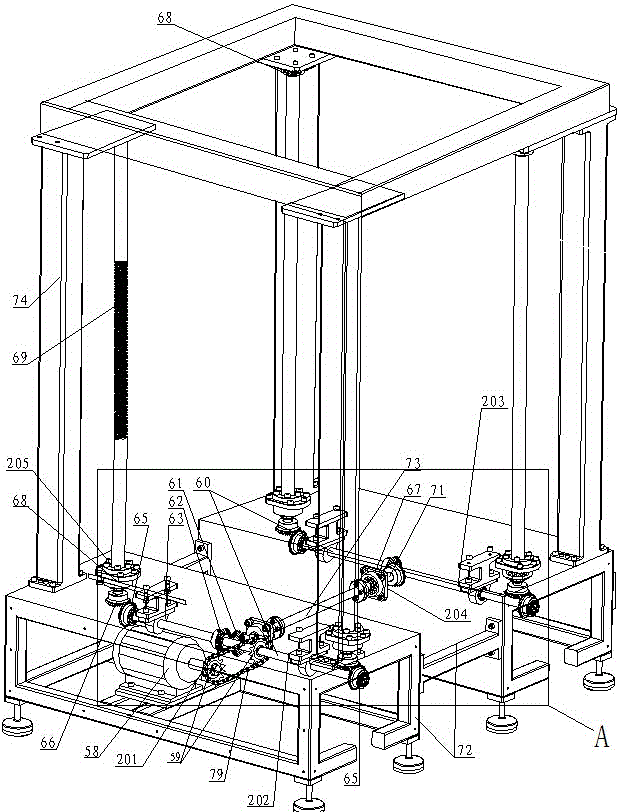

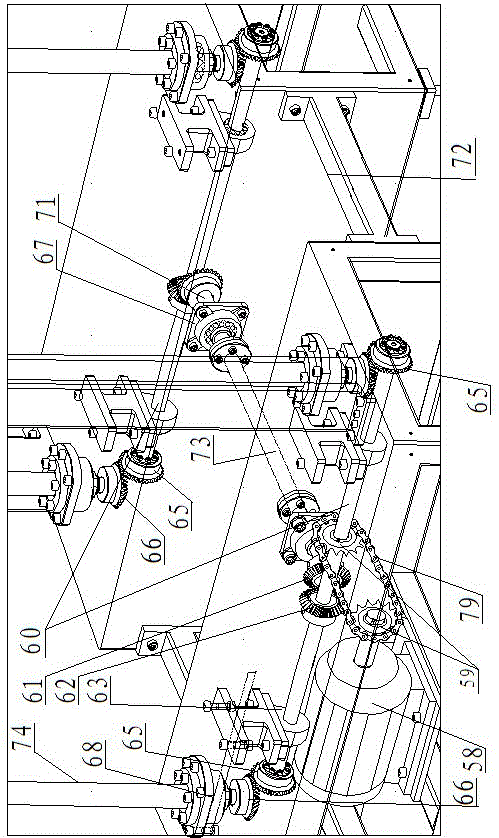

[0064] see Figure 2 to Figure 7 , in this embodiment, the lifting device 200 includes a frame 74, two cabinets 72, a power ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com