Ridging ploughshare connecting device of plate-type retest tillage implement

A technology for tillage implements and connecting devices, which is applied to agricultural machinery and implements, agricultural machinery, applications, etc. It can solve problems such as easy wear, loosening or deformation, easy change of performance of implements, change of shovel entry angle, etc., so that it is not easy to loosen or deform , Ensure that the angle of entry into the soil remains unchanged and the effect is not easy to change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

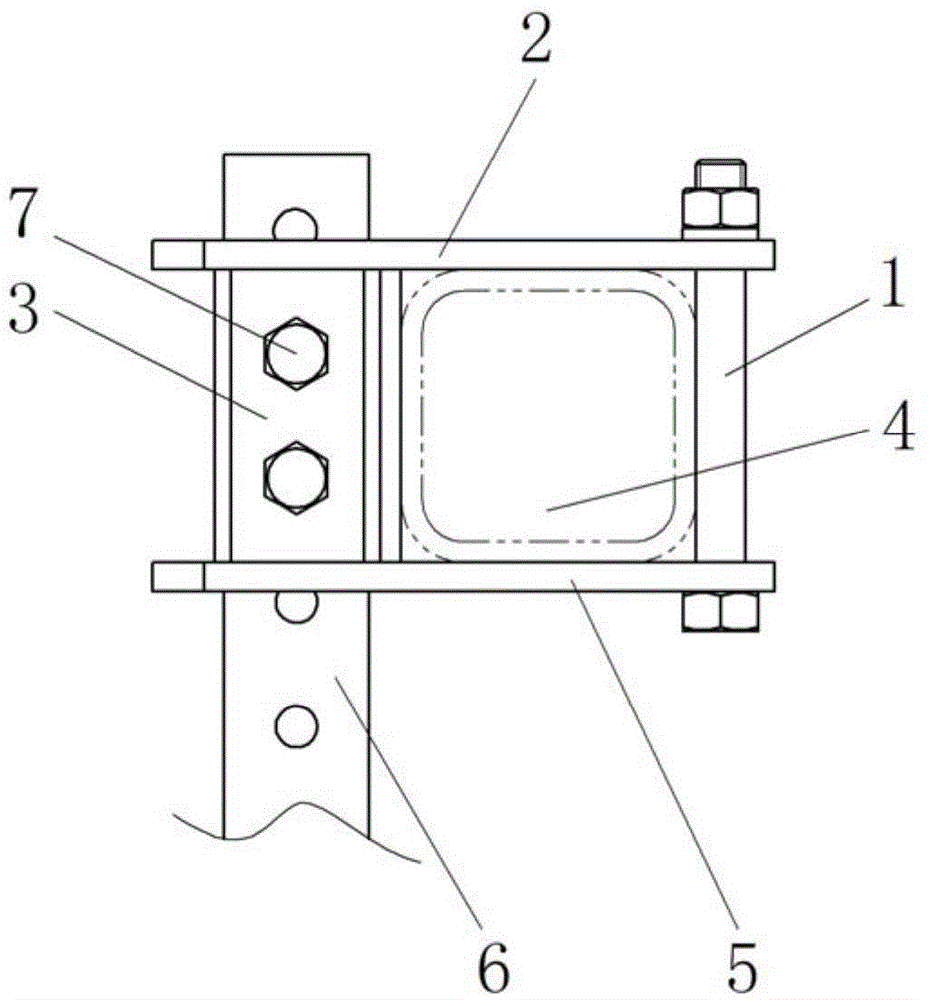

[0016] Embodiment 2, with reference to Figure 5 , Image 6 , the center of the rod ruler fixing sleeve 3 has a transparent giant opening 13, and there are two jacking screw holes 11, 12 on one side;

Embodiment 3

[0017] Embodiment 3, with reference to Figure 4 , the structure of the upper platen 2 and the lower platen 5 is the same, and the above platen 2 is an example, the giant mouth 8 that cooperates with the ridging shovel bar ruler 6 is arranged on the described upper platen 2, and the described and ridging The giant mouth 8 matched with the shovel ruler is set corresponding to the transparent giant mouth 13 in the center of the rod ruler fixing sleeve 3, and there are two light holes 19 matched with the fastening bolt 1 on one side of the upper clamping plate 2 , 10, the two optical holes on one side of the upper clamping plate 2 are coaxially corresponding to the two optical holes on the lower clamping plate 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com