Positive electrode for electricity-storage device and method for manufacturing electricity-storage device and slurry for electricity-storage-device positive electrode

A technology for positive electrode slurry and power storage device, which can be used in the manufacture of hybrid/electric double layer capacitors, battery electrodes, hybrid capacitor electrodes, etc. and other problems, to achieve the effect of excellent initial capacity, excellent capacity density, and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

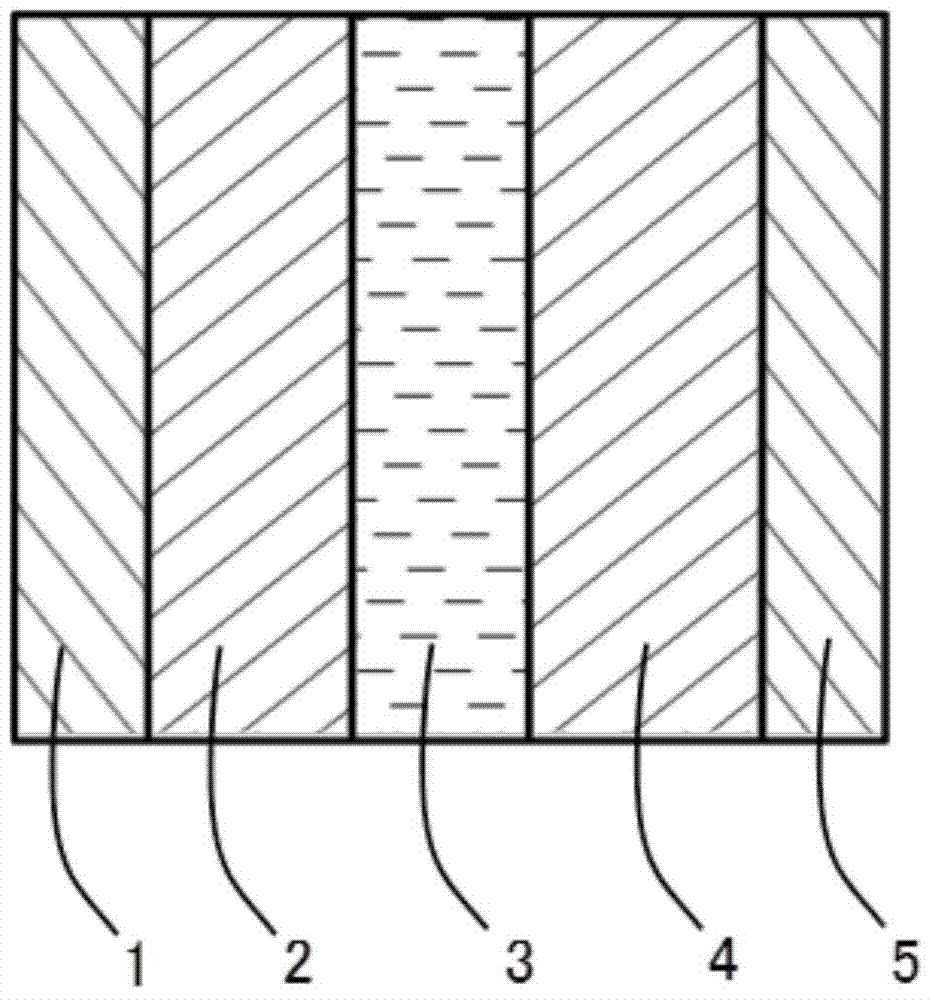

preparation example Construction

[0052] [Preparation of Conductive Polymer]

[0053] As known so far, conductive polyaniline can be obtained by electrolytically polymerizing aniline in the presence of a protic acid in a suitable solvent, or chemically oxidatively polymerizing it using an oxidizing agent. It can be obtained by oxidative polymerization of aniline with an oxidizing agent in the presence of a protonic acid. As the solvent, water is usually used, or a mixed solvent of a water-soluble organic solvent and water, or a mixed solvent of water and a nonpolar organic solvent may be used. In this case, a surfactant or the like may be used in combination.

[0054] The case where water is used as a solvent to oxidatively polymerize aniline will be described in more detail as an example. The chemical oxidative polymerization of aniline is carried out in water using a chemical oxidizing agent in the presence of a protic acid. The chemical oxidizing agent used may be either water-soluble or water-insoluble. ...

Embodiment 1

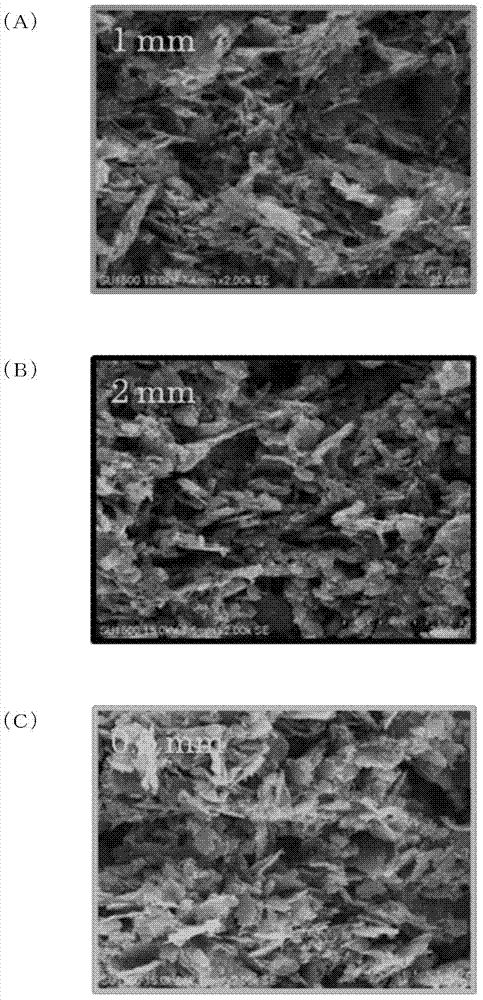

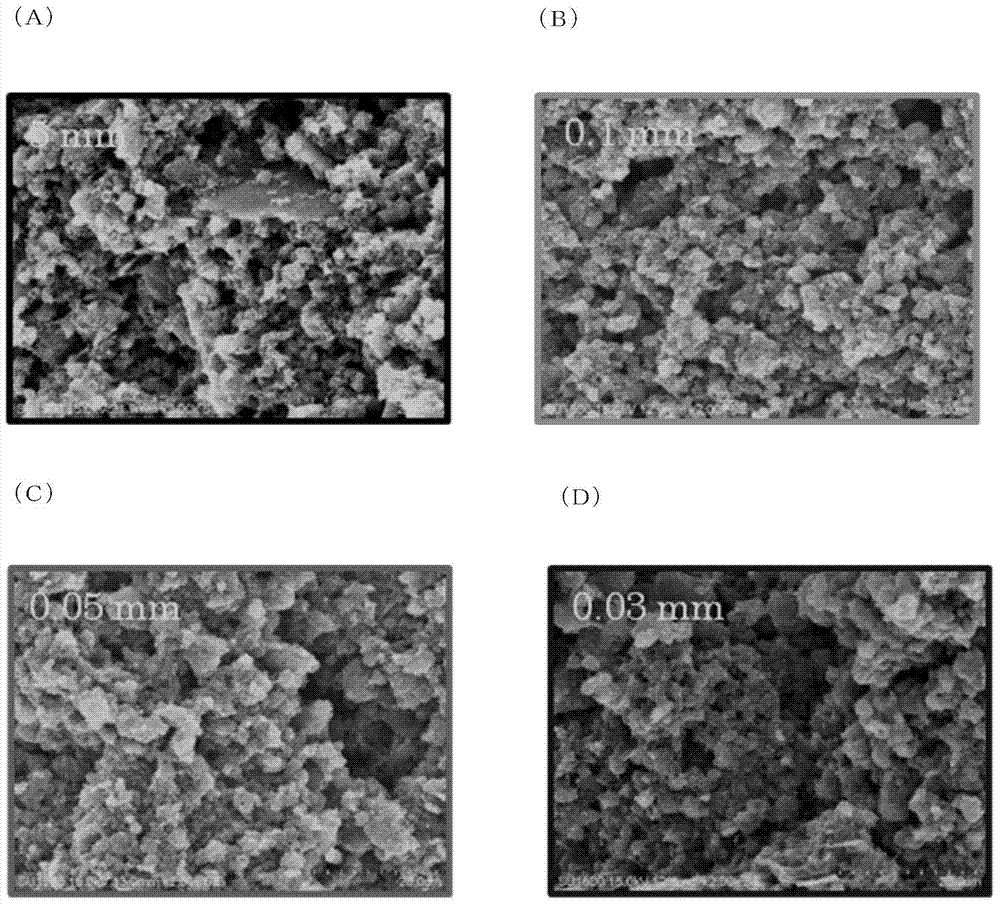

[0136] [Slurry for Example 1: 1 mm crushing ball]

[0137] After mixing 4 g of the aforementioned polyaniline powder, 0.5 g of conductive carbon black (manufactured by Denka Kagaku Kogyo Co., Ltd., DENKA BLACK) powder, and 4 g of water, it was added to 20.5 g of the aforementioned polyacrylic acid-polyacrylate lithium complex solution, and used Planetary rotary ball mill (manufactured by Fritsch Co., Ltd., P-6), using 1 mm zirconia crushing balls, the amount of crushing balls is set to 20% of the container capacity recommended by the manufacturer [for example, if it is a 250ml container, the amount of balls is 50ml (ie, 300g of balls with a specific gravity of 6g / cc)], mixed and stirred for 1 hour at a rotating speed of 400rpm. After separating the zirconia balls, the resulting slurry was subjected to a defoaming operation for 3 minutes using THINKY MIXER (manufactured by THINKY CORPORATION).

Embodiment 2

[0138] [Slurry for Example 2: 2mm crushing balls]

[0139] Use the same weight (300g) and the same capacity (50ml) mm crushing balls instead of the size 1mm of the crushing balls kneaded by the ball mill used in the preparation of the slurry in Example 1, except that it is the same as the slurry in Example 1 Operation, preparation of positive electrode slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com