Fingerprint sensor encapsulation method and structure

A fingerprint sensor and packaging structure technology, which is applied in the field of fingerprint sensor packaging methods and structures, can solve problems such as low reliability, complex fingerprint sensor packaging technology, and short-circuit risk, and achieve improved reliability, simple and reliable packaging structure, The effect of simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

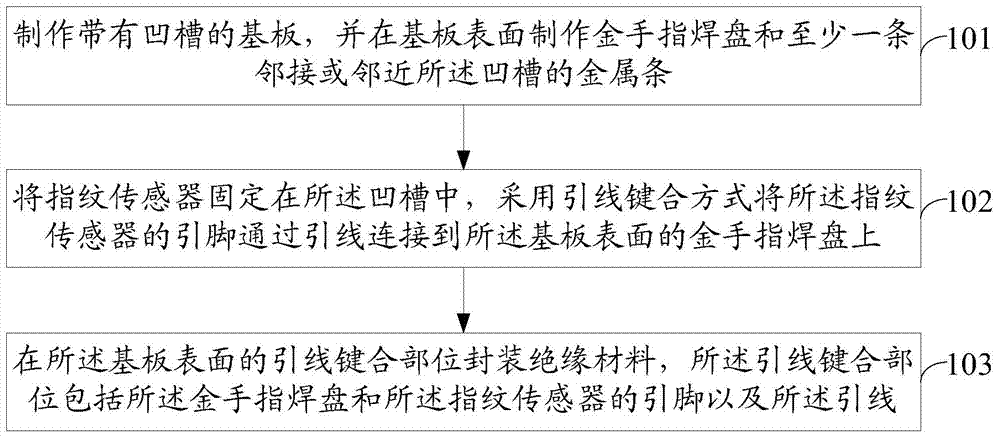

[0019] Please refer to figure 1 , an embodiment of the present invention provides a fingerprint sensor packaging method, the method comprising:

[0020] 101. Fabricate a substrate with a groove, and fabricate a gold finger pad and at least one metal strip adjacent to or adjacent to the groove on the surface of the substrate.

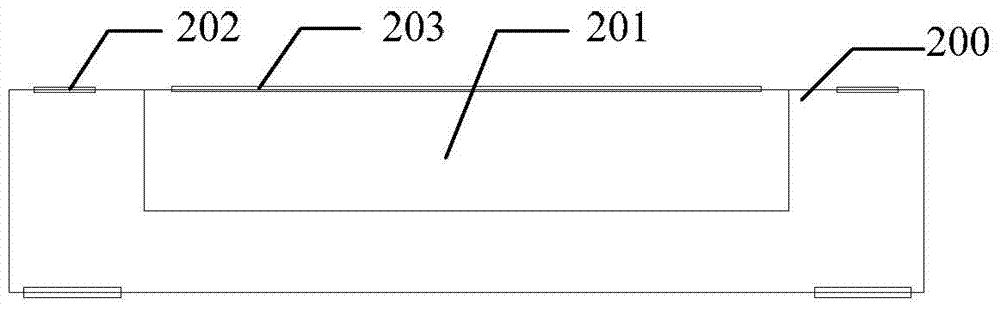

[0021] Such as Figure 2a with 2b As shown, a groove 201 is processed on the substrate 200 produced in this embodiment, and the groove 201 will be used to embed the fingerprint sensor in the future. The size of the groove matches the size of the fingerprint sensor, and the depth of the groove should be deeper than that of the fingerprint sensor. The thickness is slightly larger, for example, about 50 microns larger. The groove can be processed by means of controlled depth milling or laser etching. The position on the surface of the substrate 200 close to the groove 201 is pre-processed with gold finger pads 202 for connecting with pins on the fingerp...

Embodiment 2

[0035] Please refer to Figure 5a with 5b , an embodiment of the present invention provides a fingerprint sensor packaging structure, including:

[0036] A substrate 200 with a groove 201 and a fingerprint sensor 300 fixed in the groove 201, the surface of the substrate 200 has at least one metal strip 203 adjacent to or adjacent to the groove 201, the lead of the fingerprint sensor 300 The pins are connected to the gold finger pads 202 on the surface of the substrate 200 through wires 204, and the wire bonding parts on the surface of the substrate 200 are covered with insulating materials, and the wire bonding parts include the gold finger pads 202 and the The pins of the fingerprint sensor 300 and the leads 204 are described.

[0037] In one embodiment, the groove 201 is a rectangular groove, and two metal strips 203 are adjacent to or adjacent to two opposite side walls of the rectangular groove 201 and distributed on the surface of the substrate 200 .

[0038] Optionall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com