Preparation method of field cut-off type insulated gate bipolar transistor

A technology of bipolar transistors and insulated gates, which is applied in the direction of transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., and can solve problems such as easy scratches on wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

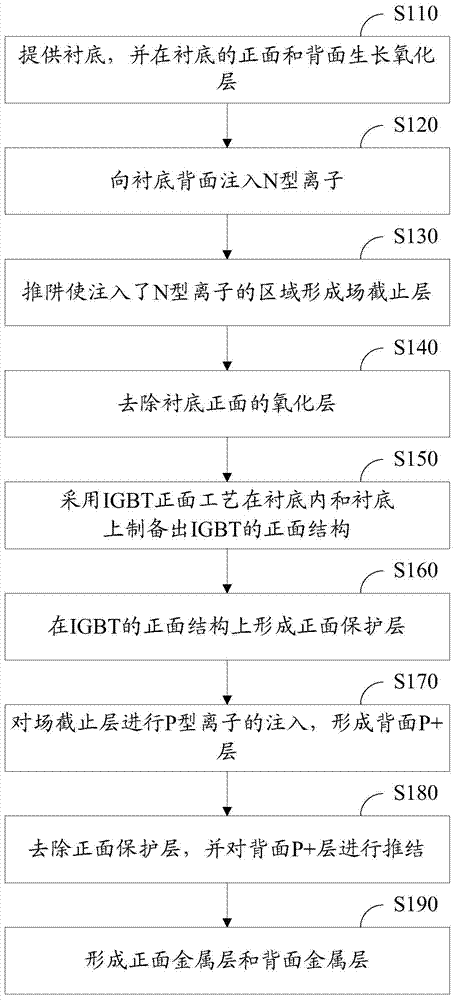

[0019] figure 1 It is a flowchart of a method for preparing a field-stop type insulated gate bipolar transistor according to an embodiment, including the following steps:

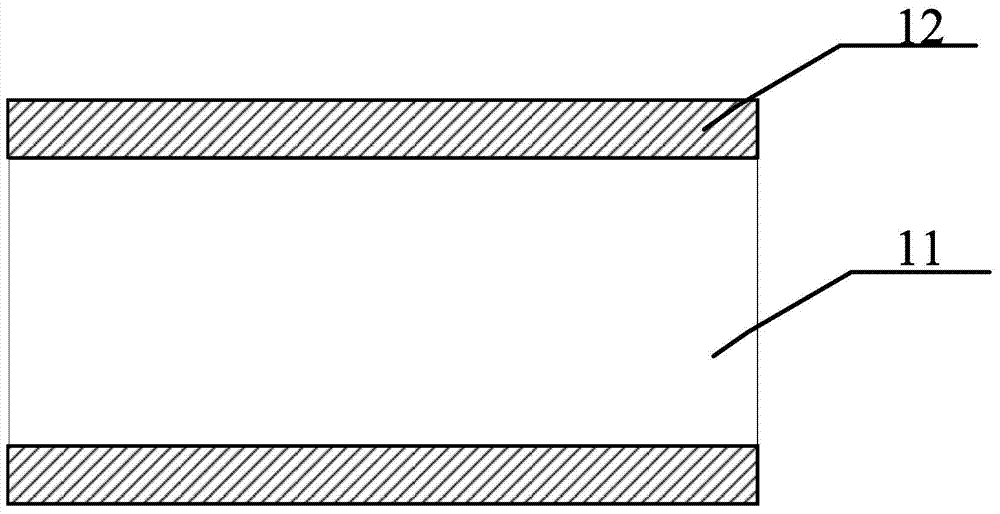

[0020] S110, providing a substrate, and growing an oxide layer on the front side and the back side of the substrate.

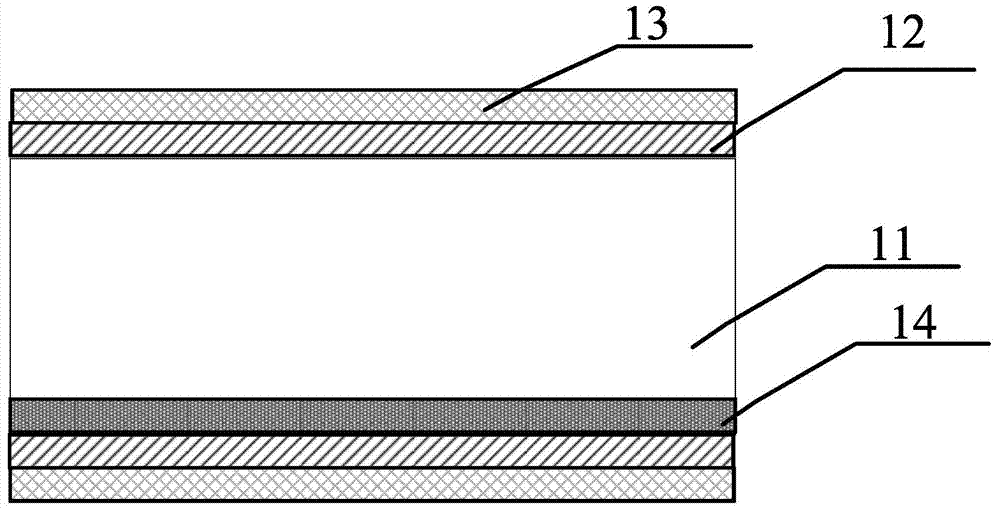

[0021] In this embodiment, a Raw Wafer with a thickness of about 400 microns is used as the substrate 11, and the first oxide layer 12 is grown on the front and back sides of the substrate 11, referring to Figure 2A . It can be understood that in this embodiment, due to process limitations, oxide layers are formed on the front and back sides at the same time. In the drawings, the oxide layers on the front and back sides of the substrate 11 are collecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com