Ring removing method of Taiko thinning process

A technology, the technology of Taiko, which is applied in the ring removal field of the Taiko thinning process, can solve the problems of edge chipping, wafer breaking, fragmentation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

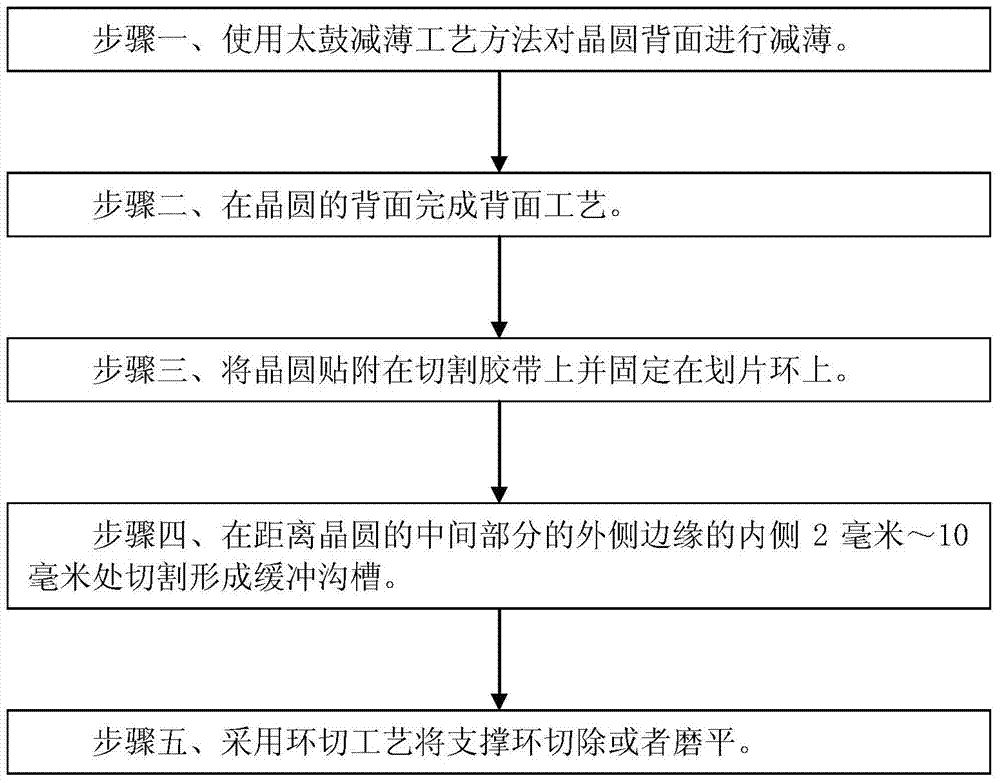

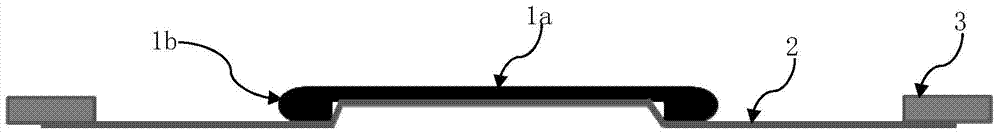

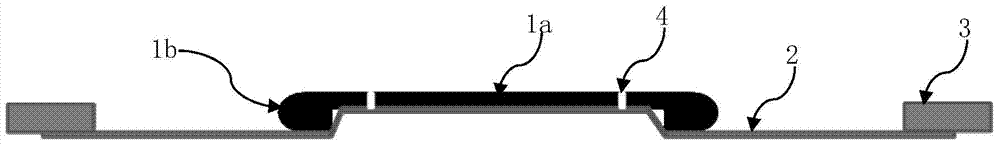

[0026] Such as figure 1 Shown is the flow chart of the method of the embodiment of the present invention; Figure 2A to Figure 2D Shown is a schematic diagram of the wafer structure in each step of the method of the embodiment of the present invention. The deringing method of Taiko drum thinning process in the embodiment of the present invention comprises the following steps:

[0027] Step 1, such as Figure 2A As shown, the back of the wafer is thinned using the Taiko thinning process, the middle portion 1a of the wafer is thinned to a required thickness, and the edge portion of the wafer is not thinned to form a support ring 1b.

[0028] The middle portion 1a of the wafer is used to form integrated circuit devices. Preferably, the thickness of the middle part 1a of the wafer after backside thinning is 25 microns to 200 microns, and the specific thickness can be adjusted according to the needs of integrated circuit devices.

[0029] The support ring 1b is used to support ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com