A product automatic assembly design system based on pro/e

A technology for automatic assembly and design systems, applied in computing, instruments, electrical digital data processing, etc., can solve problems such as long product design cycle, waste of design experience, failure to effectively manage product series, etc., to shorten the design cycle, shorten time, improving design quality and design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

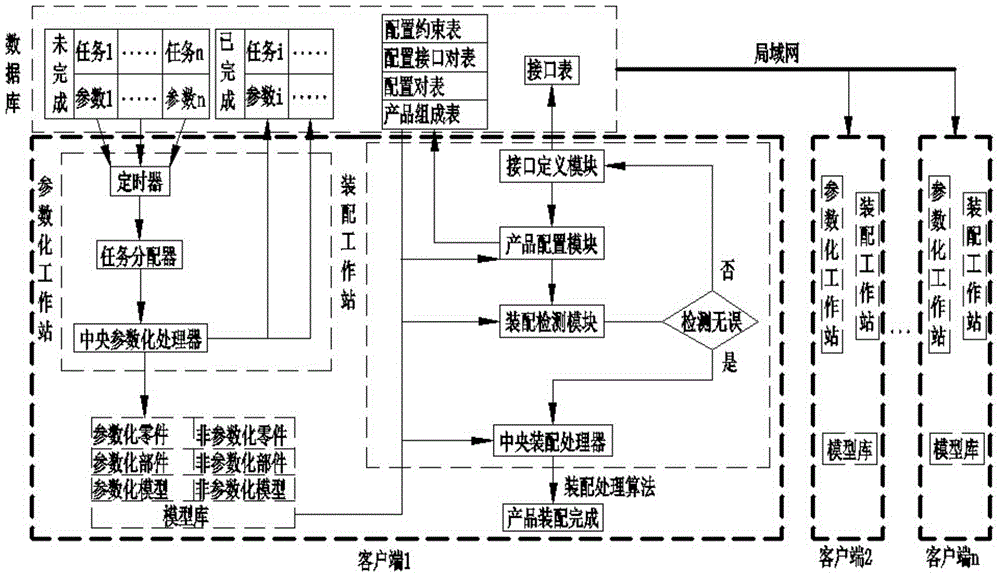

[0043] In this embodiment, a Pro / E-based product automatic assembly design system is used in product design for parametric model design and model assembly according to different design requirements; parametric model design includes parametric part design and parameters In this system, there is still a non-parametric model composed of non-parametric parts and non-parametric components. Model assembly can be an assembly between any parametric model and non-parametric model. See figure 1 , The automatic assembly design system consists of: n clients installed with Pro / E software and a shared database; the shared database is used as a data storage tool for multiple clients to achieve collaborative work; n clients are supported by the shared database. Collaborative design can be realized.

[0044] The shared database contains a list of unfinished parts consisting of several unfinished part task items and unfinished part parameter items corresponding to a number of unfinished part task i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com