Downhole tool high-temperature and high-pressure simulation test device and test method

A high-temperature, high-pressure, simulation test technology, applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problem of inability to effectively simulate the working state of tools, lack of test methods for simulation test devices, and lack of scientific and effective technical means, etc. problem, to achieve the effect of humanized operation software interface, simple structure and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

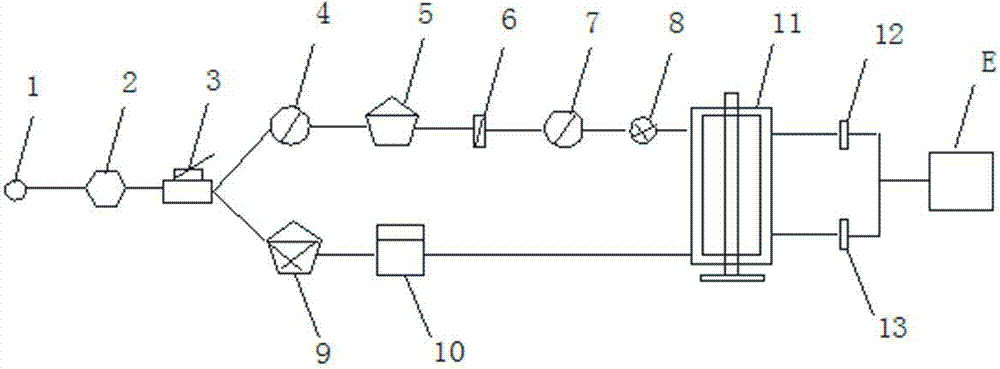

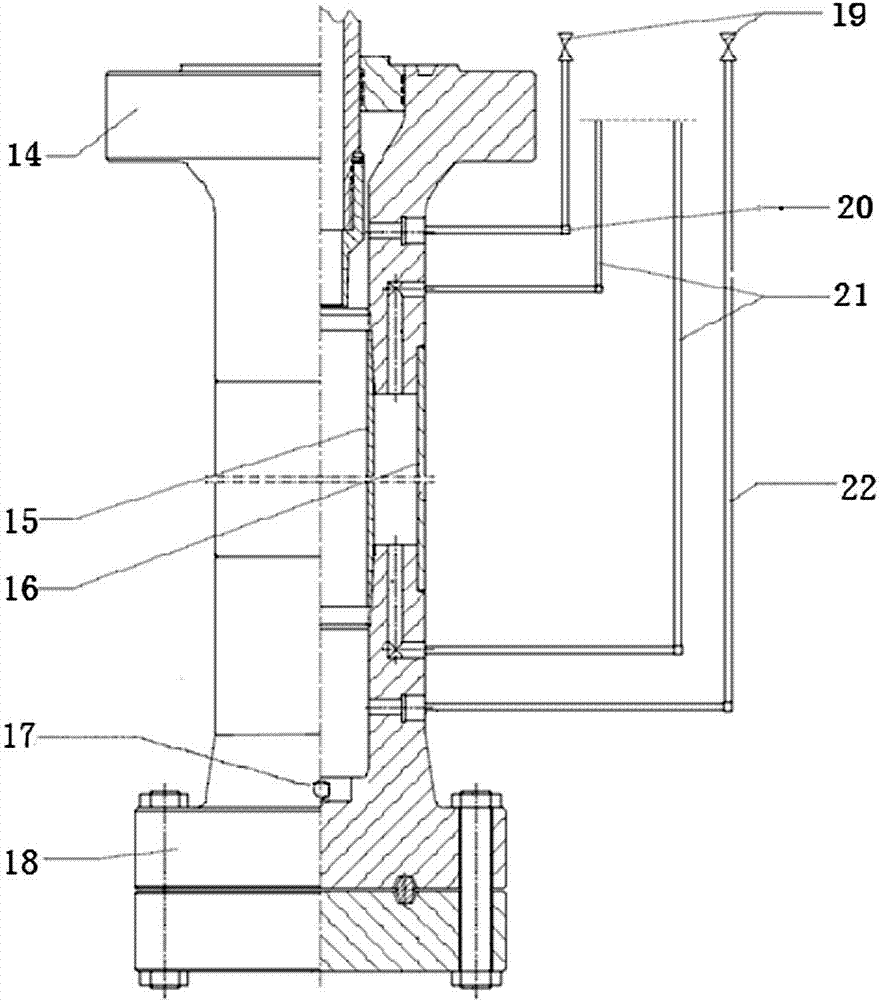

[0031] A high-temperature and high-pressure simulation test device for downhole tools, including a simulated wellbore and a supporting low-pressure drive system, a high-pressure oil system, a high-temperature circulation system, and a temperature and pressure measurement system for the simulated wellbore. The inner pipe and the outer pipe are connected between the blind flanges, and an annular heating chamber is formed between the inner and outer pipes. The upper and lower ends of the inner pipe are respectively connected with the casing flange and the inner wall of the casing blind flange through the isolation plate to form the upper and lower ends. A pressure chamber, where a conversion joint and an inner pipe fishing joint are arranged in the upper pressure chamber of the casing flange, and the inner pipe fishing joint protrudes from the opening of the outer section of the casing flange and is tightly connected with the upper sealing plug; the high temperature cycle The syst...

Embodiment 2

[0045] Embodiment 2, a typical application embodiment.

[0046] The high-temperature and high-pressure simulation test device for downhole tools includes a low-pressure drive system, a high-pressure oil system, a high-temperature circulation system, a temperature and pressure measurement system, a simulated wellbore, and a computer-controlled acquisition and video monitoring system. The low-pressure drive system is responsible for providing the power source for the high-pressure oil system, the high-pressure oil system is responsible for providing the simulation test pressure, the high-temperature circulation system is responsible for injecting heating oil into the simulation device to provide a high-temperature environment, and the temperature and pressure measurement system is responsible for sampling the temperature and pressure data, simulating The wellbore is mainly to simulate the working conditions of the tool downhole, and the computer control acquisition and video moni...

Embodiment 3

[0070] A high-temperature and high-pressure simulation test device for downhole tools, including a simulated wellbore and a supporting low-pressure drive system, a high-pressure oil system, a high-temperature circulation system, and a temperature and pressure measurement system for the simulated wellbore. The inner pipe and the outer pipe are connected between the blind flanges, and an annular heating chamber is formed between the inner and outer pipes. The upper and lower ends of the inner pipe are respectively connected with the casing flange and the inner wall of the casing blind flange through the isolation plate to form the upper and lower ends. A pressure chamber, where a conversion joint and an inner pipe fishing joint are arranged in the upper pressure chamber of the casing flange, and the inner pipe fishing joint protrudes from the opening of the outer section of the casing flange and is tightly connected with the upper sealing plug; the high temperature cycle The syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com