Dynamic torsional fatigue tester for automobile transmission shaft assemblies

A torsional fatigue and test device technology, which is applied in machine gear/transmission mechanism testing, measuring devices, vehicle testing, etc., can solve the problems of short-term test bench utilization and failure to meet the dynamic torsional fatigue life test of automobile drive shafts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

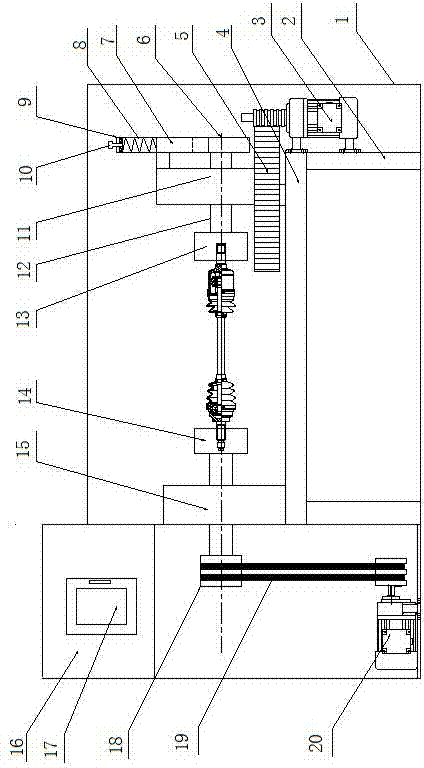

[0017] Embodiment: a dynamic torsional fatigue test device for an automobile transmission shaft assembly, which includes a bracket 2 and a base 4 arranged in a box body 1, and is characterized in that one end of the base 4 is a main deceleration drive mechanism, and the other One end is a dynamic torsion mechanism, and the space between the main reduction mechanism and the dynamic torsion mechanism is the clamping space of the drive shaft assembly under test, and a loading mechanism is also provided on the dynamic torsion mechanism.

[0018] The main deceleration drive mechanism includes a driving motor 20 arranged in the casing, a main gearbox 15 arranged on one side of the support 2, a belt 19, a main shaft 18 and a driving chuck 14, and the output end of the driving motor 20 is input to the main shaft through the belt 19. The output end of the main shaft 18 is connected with the active chuck 14 through the main gearbox 15.

[0019] The dynamic torsion mechanism includes a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com