Submersible electric pump

A technology for submersible electric pumps and motor shafts, applied to pumps, pump devices, pump components, etc., can solve the problems of increased overall weight of motor submersible electric pumps, reduced motor efficiency and power factor, and decreased overall efficiency of submersible electric pumps. Increased efficiency, reduced diffusion angle, and ease of disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

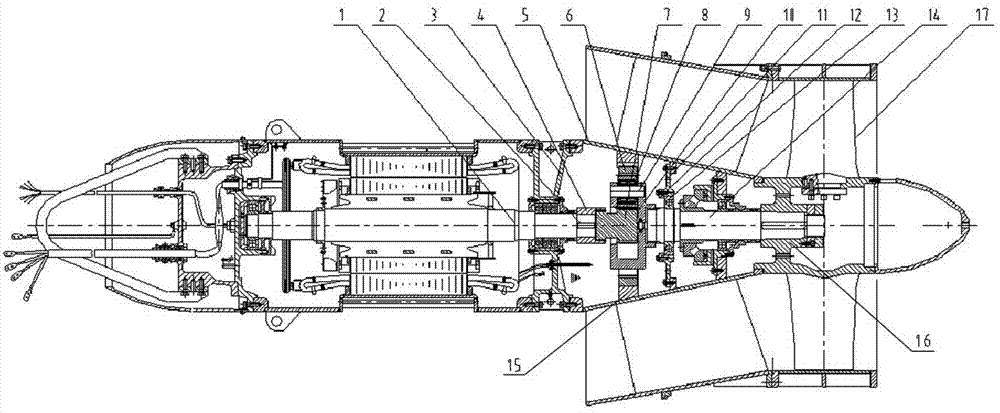

[0026] see figure 1 , figure 2 , a submersible electric pump, comprising a motor and a guide vane body 5; one end of the motor shaft 1 of the motor extends outside the end cover 3, and extends into the guide vane body 5, and is correspondingly connected to the impeller hub located in the impeller body 16. The guide vane body 5 is provided with a planetary gear reduction mechanism, and one end of the motor shaft 1 extending outside the end cover 3 is connected to the axle of the sun gear 7 of the planetary gear reduction mechanism through a coupling.

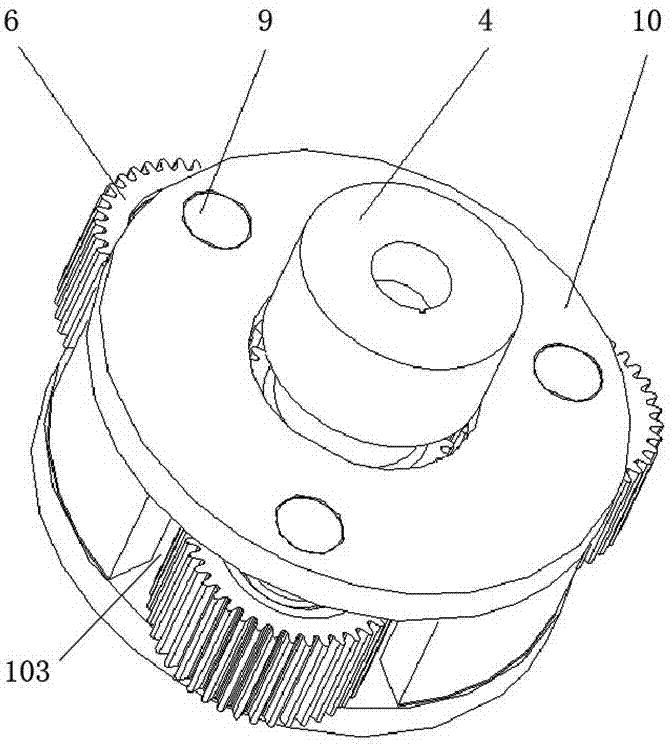

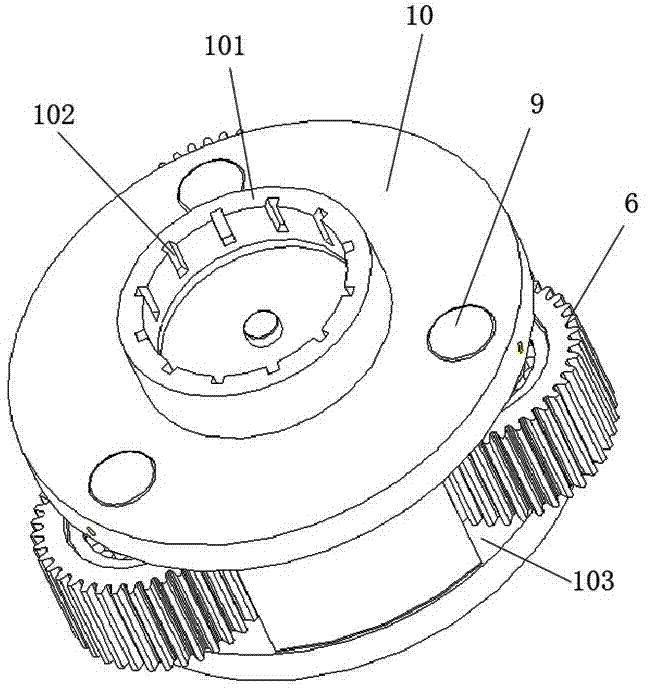

[0027] see image 3 , Figure 4 , Figure 5 , the planetary gear reduction mechanism is composed of a gear box 10, a ring gear 15, a sun gear system, and a planetary gear 6; 15 is coaxially provided with a gear box 10 in the shape of a circular box, and a sun gear system is arranged axially in the middle of the gear box 10; The wheel shaft extends out of the second sun gear 701 on the end of the gearbox 10, and the second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com