Graphite purification furnace with stirring device and lifting lugs

A technology of graphite purification furnace and stirring device, which is applied in the field of graphite purification furnace, and can solve problems such as difficulty in transportation, prolonging heater heating time, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention will be further described below in conjunction with the accompanying drawings.

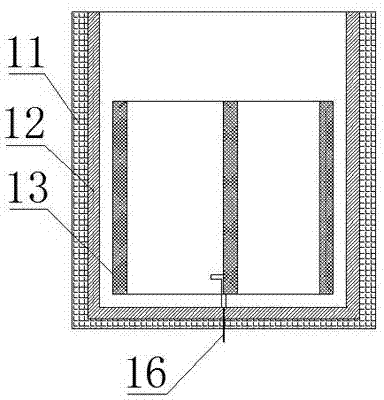

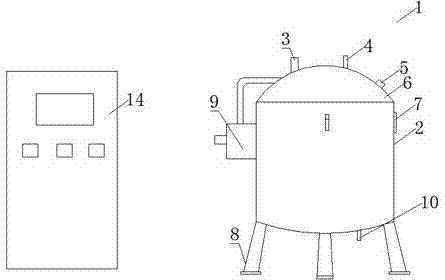

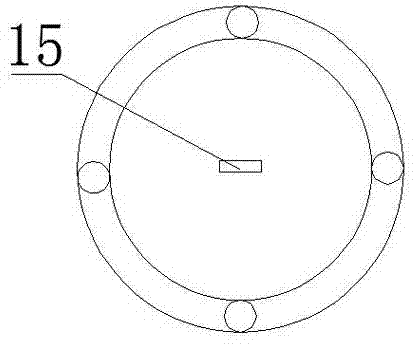

[0018] like figure 1 , 2 , 3, and 4, the purification furnace furnace body 1 is composed of a furnace body 2 and a furnace cover 6, the furnace cover is provided with an air inlet 3, a temperature measuring port 4 and an observation port 5, and the furnace body 2 has a furnace cover Control unit 9, the furnace cover 6 is connected with the furnace body through the furnace cover control unit 9, the bottom of the furnace body 2 also has a foot 8 supporting the furnace body 2, and the bottom of the furnace body 2 also has an exhaust port 10, which is used to discharge the Gasified graphite impurities, one side of the furnace body 1 has a control cabinet 14, which is used to control the working state of the heater 13, and one side of the furnace body 1 also has an air extraction port 7, which is used to be connected with a vacuum pump to realize the internal heating of the furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com