A continuous preparation method and device for nano-silver wire

A nano-silver wire and filtering device technology, applied in nanotechnology and other directions, can solve problems such as unfavorable industrial production, many steps required, harsh reaction conditions, etc., and achieve convenient production or basic research, simple and feasible steps, and safe and simple equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

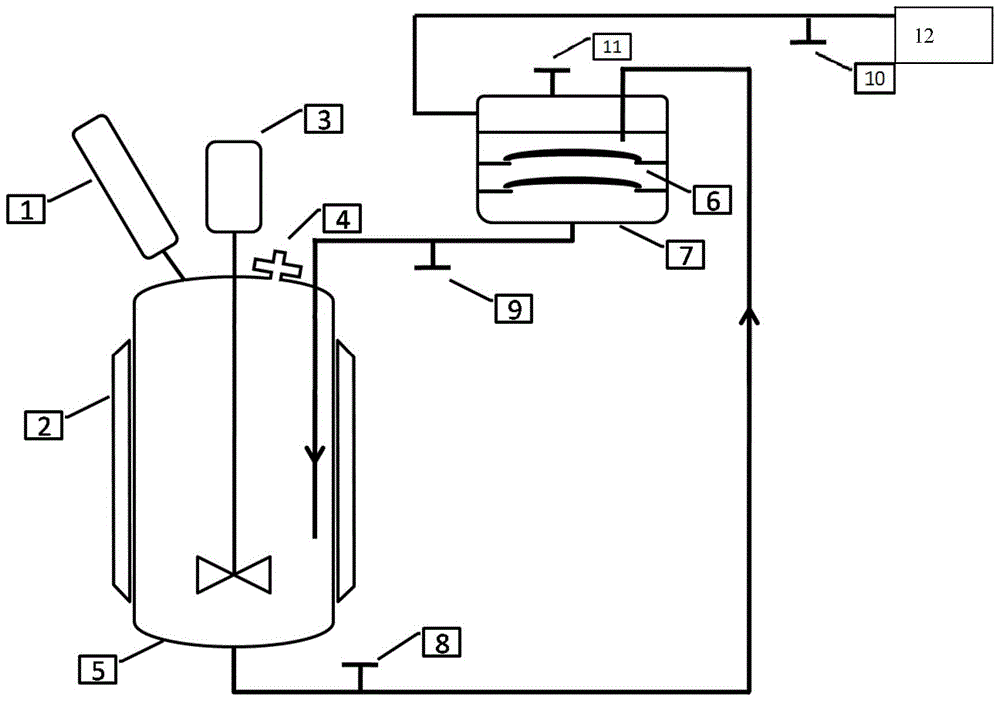

Method used

Image

Examples

Embodiment 1

[0037] (1) Raw material premixing

[0038] According to the mass ratio of ethylene glycol: polyvinylpyrrolidone: silver nitrate is 1:0.024:0.018 to take materials; 2 liters (density is 1.111 g / ml) ethylene glycol, 80.00 grams of polyvinylpyrrolidone and 2.7 mg of sodium chloride from the feed Port 4 is put into the reaction kettle 5 with a capacity of 5 liters for mixing, and the stirrer 3 is started to stir and the temperature is raised to 160°C. At this time, the stirring speed is 180r / min, and the stirring time is 1h. Observe the color change of the solution (preliminary judgment of the degree of mixing) , to obtain liquid A; 1 liter of ethylene glycol and 60.00 grams of silver nitrate were stirred and dissolved, the stirring speed was 200r / min, and the stirring time was 1h, and liquid B was obtained for subsequent use; wherein the number average molecular weight of polyvinylpyrrolidone was 58000;

[0039] (2) Liquid phase reduction

[0040] Add liquid B obtained in step (...

Embodiment 2

[0048] (1) Raw material premixing

[0049] According to the mass ratio of ethylene glycol: polyvinylpyrrolidone: silver nitrate is 1:0.027:0.024. Put 2 liters (density 1.111 g / ml) of ethylene glycol, 90.00 g of polyvinylpyrrolidone and 3.6 mg of potassium chloride into a reactor with a capacity of 5 liters from the feed port and mix, stir and heat up to 160 ° C, then stir The speed is 180r / min, the stirring time is 1h, observe the color change of the solution (preliminary judgment of the degree of mixing), and obtain liquid A; stir and dissolve 1 liter of ethylene glycol and 80.00 grams of silver nitrate. The stirring speed is 200r / min, and the stirring time is 1h. Obtain liquid B; wherein the number average molecular weight of polyvinylpyrrolidone is 58000;

[0050] (2) Liquid phase reduction

[0051] Add liquid B obtained in step (1) dropwise from the feed port to liquid A obtained in step (1) at a constant speed (the drop rate is 0.6mL / s), keep the reaction temperature at...

Embodiment 3

[0059] (1) Raw material premixing

[0060] According to the mass ratio of ethylene glycol: polyvinylpyrrolidone: silver nitrate is 1:0.030:0.024 to take materials. Put 2 liters (density 1.111 g / ml) of ethylene glycol, 100.00 g of polyvinylpyrrolidone and 3.6 mg of ferric chloride into a reactor with a capacity of 5 liters from the feed port and mix, stir and heat up to 160 ° C, then stir The speed is 180r / min, the stirring time is 1h, observe the color change of the solution (preliminary judgment of the degree of mixing), and obtain liquid A; stir and dissolve 1 liter of ethylene glycol and 80.00 grams of silver nitrate. The stirring speed is 200r / min, and the stirring time is 1h. Obtain liquid B; wherein the number average molecular weight of polyvinylpyrrolidone is 58000;

[0061] (2) Liquid phase reduction

[0062] Add liquid B obtained in step (1) dropwise from the feed port to liquid A obtained in step (1) at a constant speed (the drop rate is 0.6mL / s), keep the reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com