A Long Stroke Control Method for Rough Rolling Width Multi-target Rolling

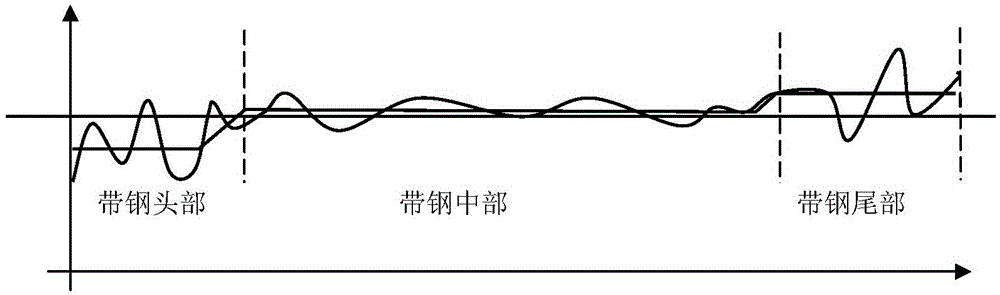

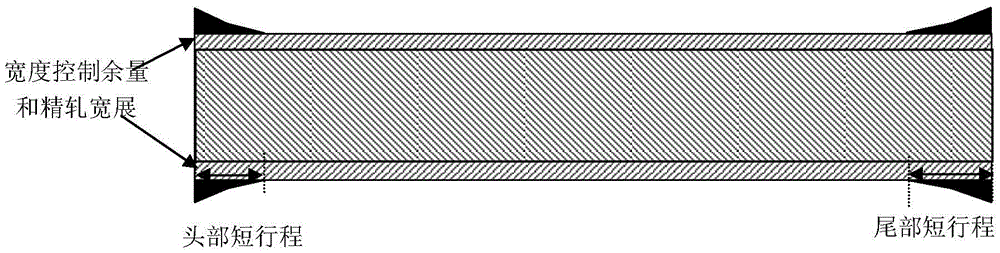

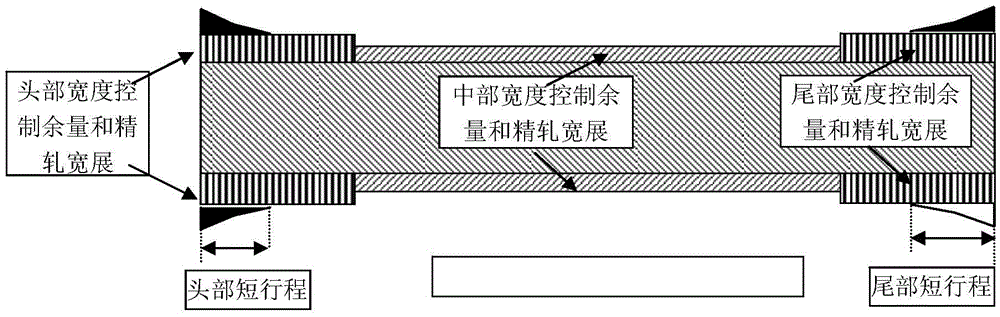

A control method and multi-objective technology, which is applied in the long-stroke control field of multi-objective rolling of rough rolling width, can solve the problem of uneven width and spread of finishing rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0115] Rough rolling three-stage target control,

[0116] Vertical roller diameter: Ediaroll=1200.0mm;

[0117] Horizontal roll diameter: diaroll=1246.0mm;

[0118] Rough rolling 3-3 pass rolling;

[0119] (1) Step 1: Prepare rough rolling data.

[0120] E3 vertical roll reduction: E3Red=5.0mm

[0121] E3 dog bone spread: E3dogSpread=4.14mm;

[0122] Finished natural wide spread genetic coefficient head: InherFMSpreadH=-1.70mm;

[0123] The middle part of the genetic coefficient of finishing rolling natural widening: InherFMSpreadH=-1.20mm;

[0124] Finished natural wide spread genetic coefficient tail: InherFMSpreadH=-1.50mm;

[0125] Coefficient of thermal expansion: alfa=1.01;

[0126] Width margin learning value W MarginInher = 1.60.10.9 (mm);

[0127] Rough rolling target width system HMI correction value: W HMI =0.00.00.0 (mm);

[0128] Width allowance process correction value: W MarginTechnics =1.6-0.51.0 (mm);

[0129] Width margin basic value W MarginBas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com