Method for producing a pressure sensor and corresponding sensor

By depositing conductive materials and diffusion barrier layers in the pressure sensor after assembling the support substrate and the deformable membrane, and integrating the housing with thermal lamination technology, the temperature limitations of the oil packaging and the influence of intermediate components in the existing technology are solved, and the sensor is improved. accuracy and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

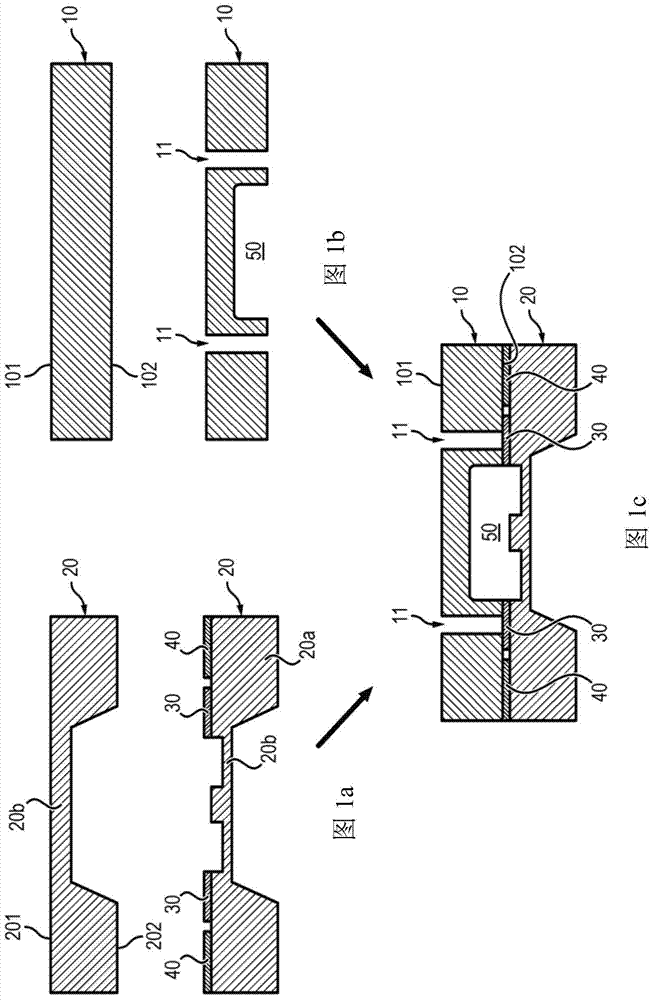

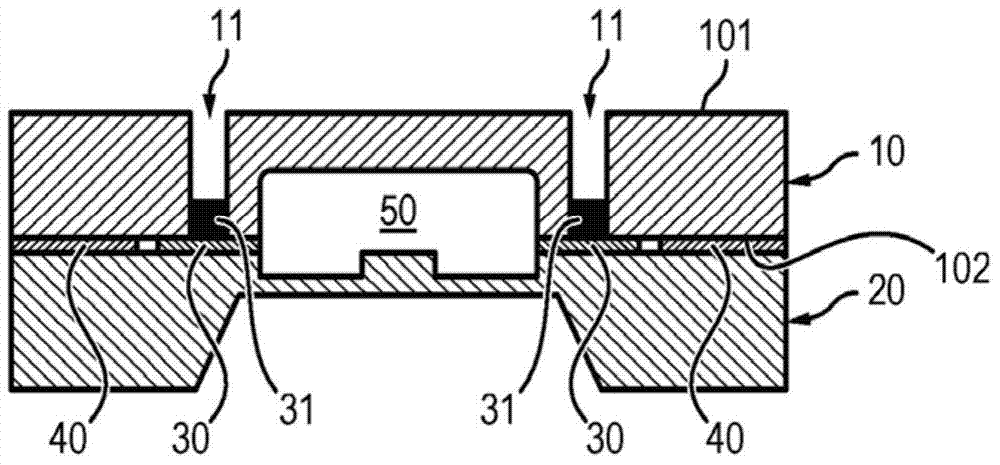

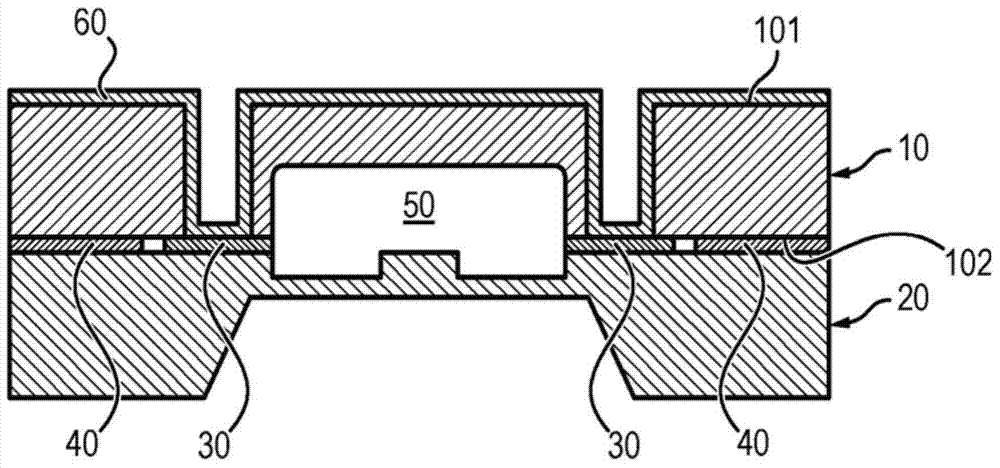

[0049] A pressure sensor comprises, inter alia, a support 10 and a deformable membrane 20 , a strain gauge 30 and an assembly support 40 arranged between the support 10 and the membrane 20 .

[0050] Measurement of pressure can be absolute or differential.

[0051] The micromechanical structure formed by the deformable membrane and the strain gauges is thus protected by the support 10 .

[0052] The micromechanical structure is electrically connected to the housing 80 through the support part 10 comprising electrical contacts 61 , and the housing 80 further comprises electrical contacts 81 provided inside.

[0053] Advantageously, the deformable membrane 20 comprises an upper surface 201 and a lower surface 202, a pressure-sensitive membrane and / or a thin portion 20b suspended above the free space, and a thick portion 20a forming a support for the thin portion 20b.

[0054] Such a membrane 20 is generally formed from a substrate, for example comprising single crystal silicon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com