An Equivalent Air Gap Adjustable Reactor

A technology for adjusting reactance and air gap, which is applied in the direction of variable inductors, inductors, variable transformers, etc., can solve the problems of insufficient attention, large reactance adjustment range, slow response speed, etc., and achieve simplified structure, Simple wiring and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

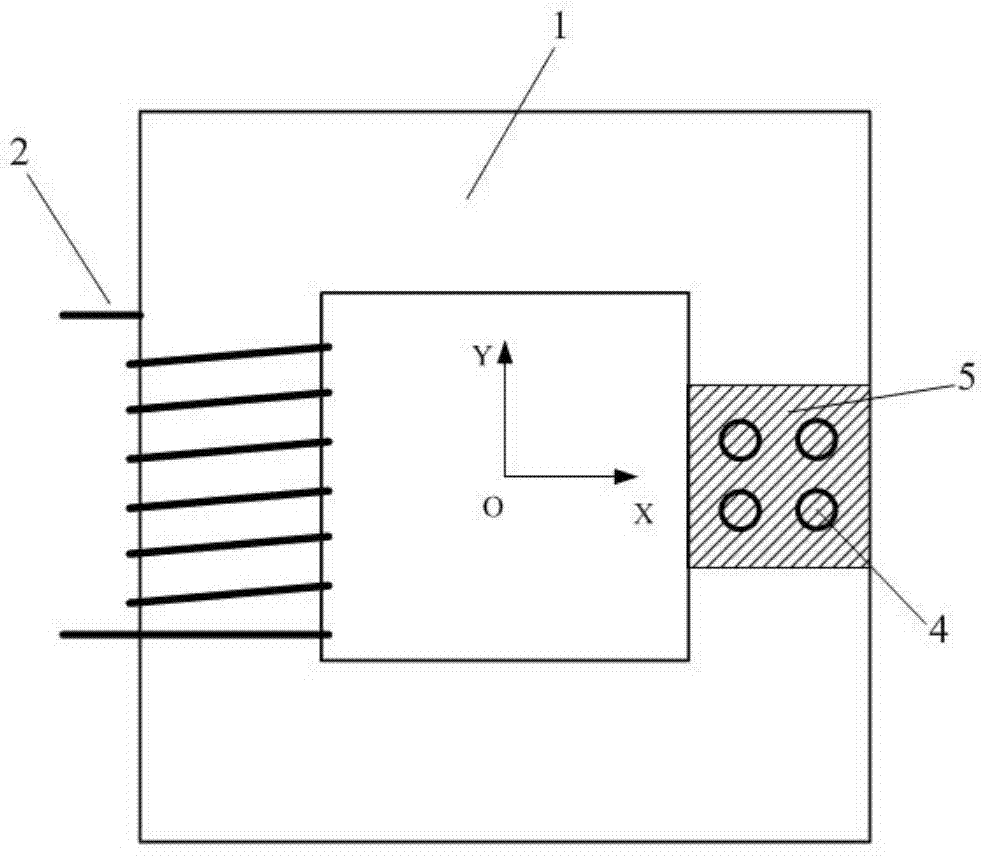

[0027] A schematic diagram of the structure of the equivalent air gap adjustable reactor described in the present invention is as follows: figure 1 As shown, it includes iron core 1, AC working winding 2 and several groups of DC equivalent air gap windings; the iron core 1 is a closed ring structure, and a rectangular coordinate system is established with the center point of the iron core 1 as the origin, and the two sides of the iron core 1 are The Y axis is symmetrical; the middle part of the iron core 1 on the left side of the Y axis is wound with an AC working winding 2, and the middle part of the iron core 1 on the right side of the Y axis is provided with several pairs of iron core holes 4, and the paired iron core holes are arranged symmetrically on both sides of the X axis. A set of DC equivalent air-gap windings are wound in two adjacent core holes, and each set of DC equivalent air-gap windings are reversely connected in series; in the X-axis direction and Y-axis dire...

Embodiment 2

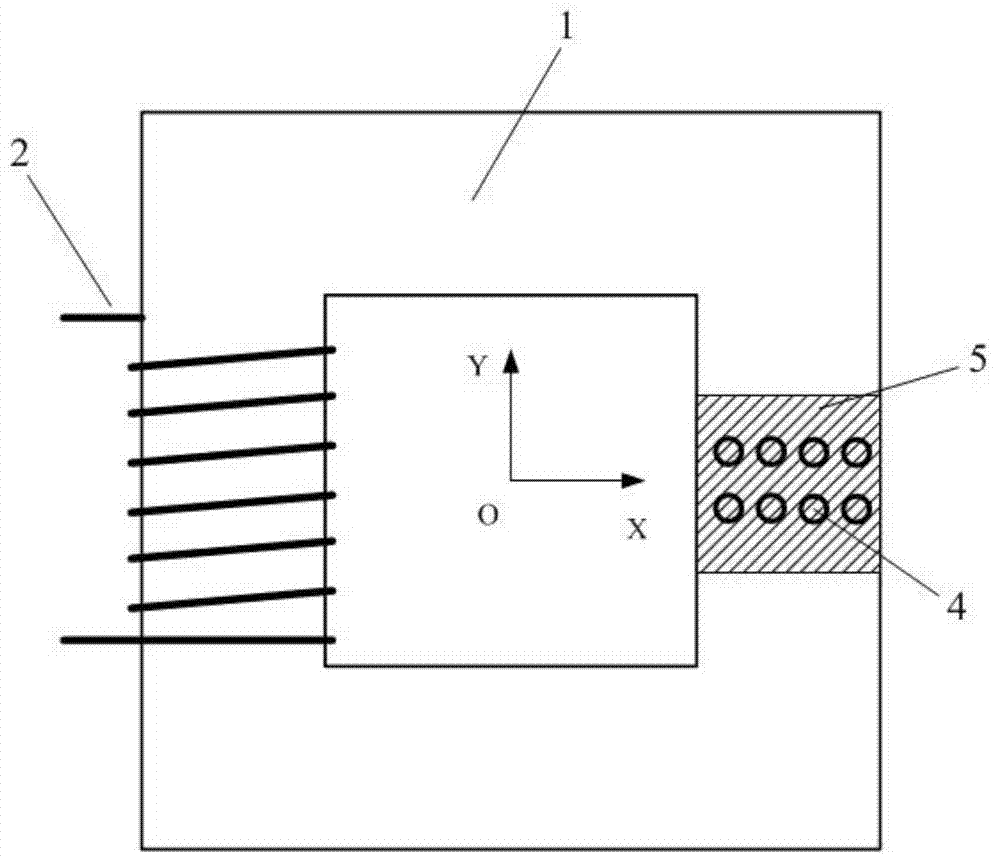

[0029] The structure diagram of an equivalent air gap adjustable reactor described in the present invention is as follows: figure 2 As shown, compared with the first embodiment, the structure has eight circular iron core holes 4 for winding four sets of DC equivalent air gap windings, so as to generate a more uniform equivalent air gap. Figure 5 For the second embodiment, four sets of DC equivalent air gap windings: 5A, 5B, 5C and 5D. Four DC equivalent air gap windings such as Figure 5 The method shown is connected in reverse series, and there are many combinations of winding methods. Figure 5 Two winding methods are given. The principle of winding is that the AC magnetic potentials induced in the four sets of DC equivalent air gap windings cancel each other out. figure 2 The middle shaded part is the flow range of the local magnetic flux 5, and the resulting local saturation can be regarded as an equivalent air gap.

Embodiment 3

[0031] A schematic diagram of the structure of the equivalent air gap adjustable reactor described in the present invention is as follows: image 3 As shown, compared with the structure of the first embodiment, two groups of square core holes 4 of the same size are arranged longitudinally on one side of the core 1, and the vertical distance between the group of square core holes 4 in the middle and the X axis is zero; that is The cross-sectional area of the middle iron core hole 4 after merging is twice that of the upper iron core hole 4 or the lower iron core hole 4 . A set of DC equivalent air gap windings is wound on adjacent square core holes 4, that is, two sets of DC equivalent air gap windings are required. If the two square iron core holes 4 in the middle are separated, the magnetic flux generated between the two square iron core holes 4 due to the winding mode of the DC equivalent air gap winding cancels each other, and the magnetic flux is zero, which is equivalent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com