Optimized distribution method of detection points on body wall board of large airplane

A technology of aircraft fuselage and layout method, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of increasing assembly deformation estimation error and reducing the accuracy of panel pose evaluation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Such as figure 1 As shown, the posture adjustment and positioning system for large aircraft fuselage panels is mainly composed of large aircraft fuselage panels 1 , numerical control positioners 2 and process joints 3 .

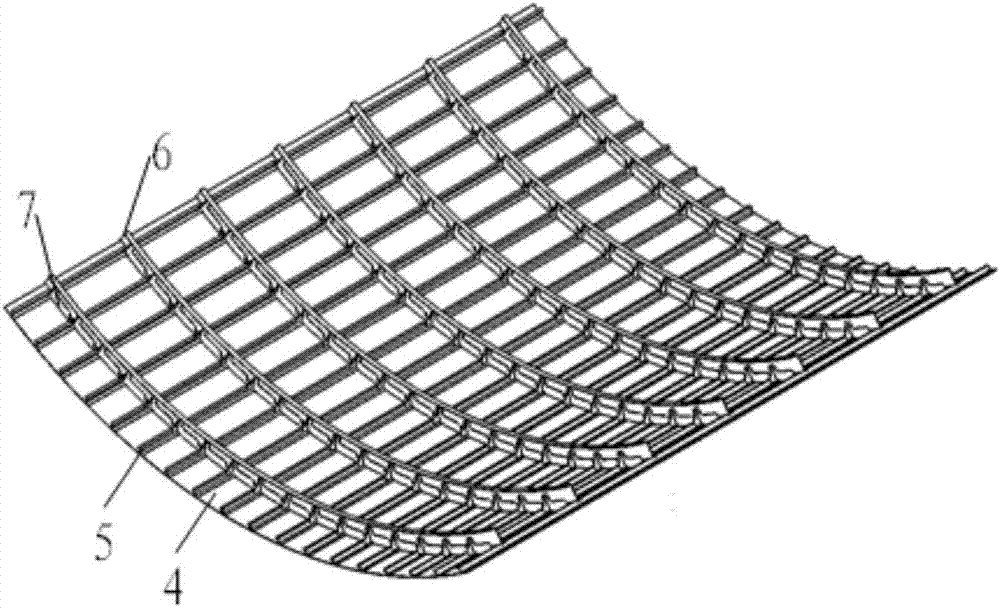

[0044] Such as figure 2 As shown, the large aircraft fuselage panel 1 is mainly composed of skin 4, stringer 5, bulkhead 6, corner piece 7 and other parts.

[0045] Such as image 3 As shown, the process joint 3 of the large aircraft fuselage panel 1 is mainly composed of a process ball joint 8 and a joint body 9 .

[0046] Such as Figure 4 As shown, the numerical control positioner 2 is mainly composed of an X-direction moving axis 10, a Y-direction moving axis 11, and a Z-direction moving axis 12, and each axis moves independently.

[0047] Such as Figure 5 As shown, the initial set of detection points to be selected is composed of multiple detection points 13 on the frame 6 .

[0048] The steps of the method for optimizing the layout of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com