Device for detecting defects of insulating tool for hot-line work

A technology for defect detection and insulation tools, applied in measuring devices, material analysis by electromagnetic means, instruments, etc., can solve problems such as low detection efficiency, inability to use live work immediately, and inability to comprehensively detect insulation tools, and achieve safe detection. , the effect of high-efficiency security detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

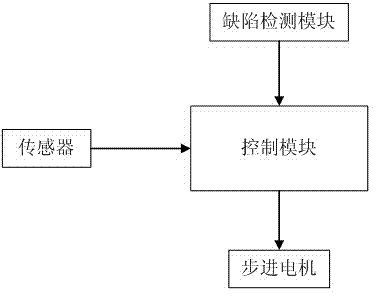

[0016] Such as figure 1 As shown, a defect detection device for insulating tools for live working, including a sensor, a control module, a defect detection module for inter-layer detection and layer-along detection, and a stepping motor, the output of the defect detection module and the input of the control module The output terminal of the sensor is connected with the input terminal of the control module, and the output terminal of the defect detection module is connected with the stepper motor.

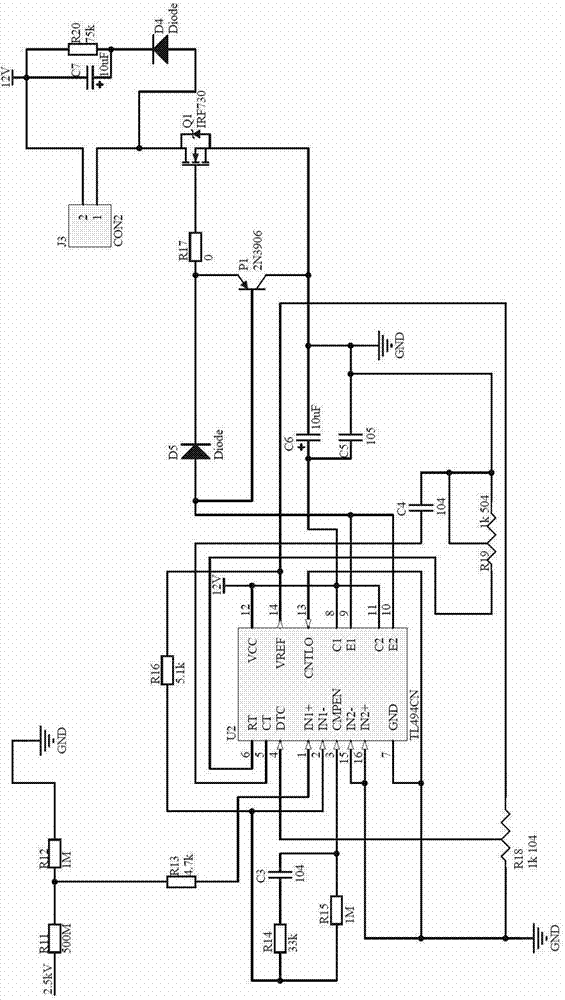

[0017] Such as figure 2 As shown, the defect detection module includes TL494 chip, triode P1, field effect transistor Q1, diode D4 and diode D5, the IN+ input terminal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com