Concrete workability testing device and concrete workability testing method

A testing device and concrete technology, which is applied in the direction of measuring devices, flow characteristics, instruments, etc., can solve the problems of large influence on accuracy, large error of test results, and difficulty in accurately reflecting the real performance parameters of concrete, and achieve high precision, The operation method is simple and the effect of convenient unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in further detail below in conjunction with accompanying drawing:

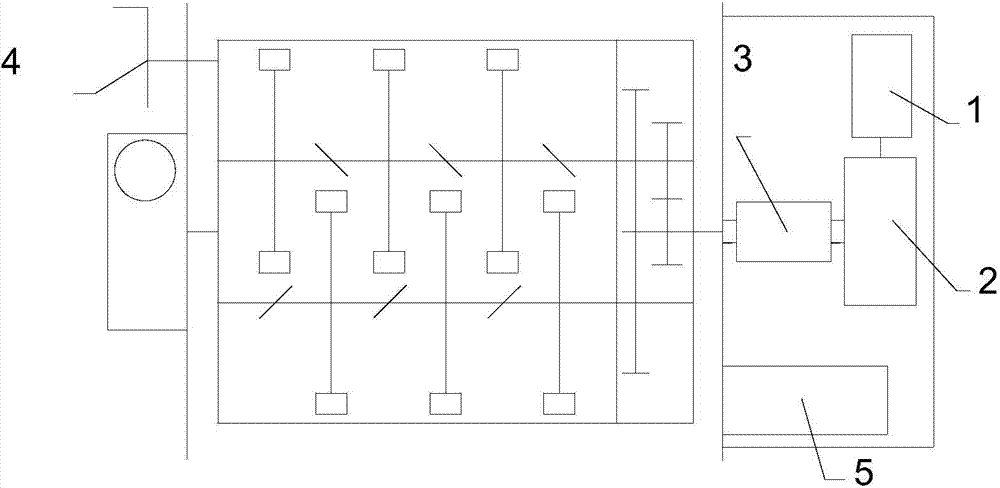

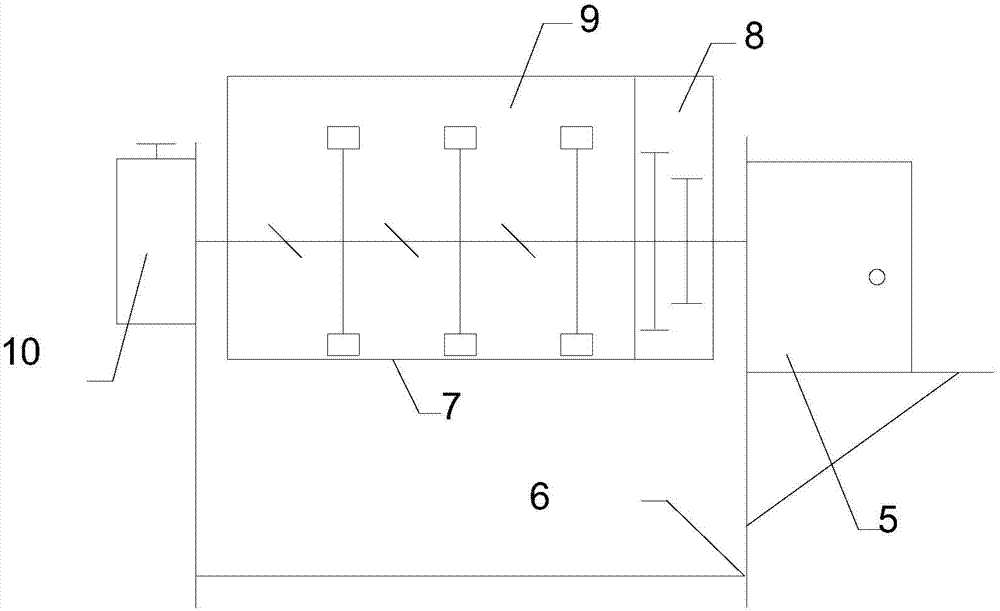

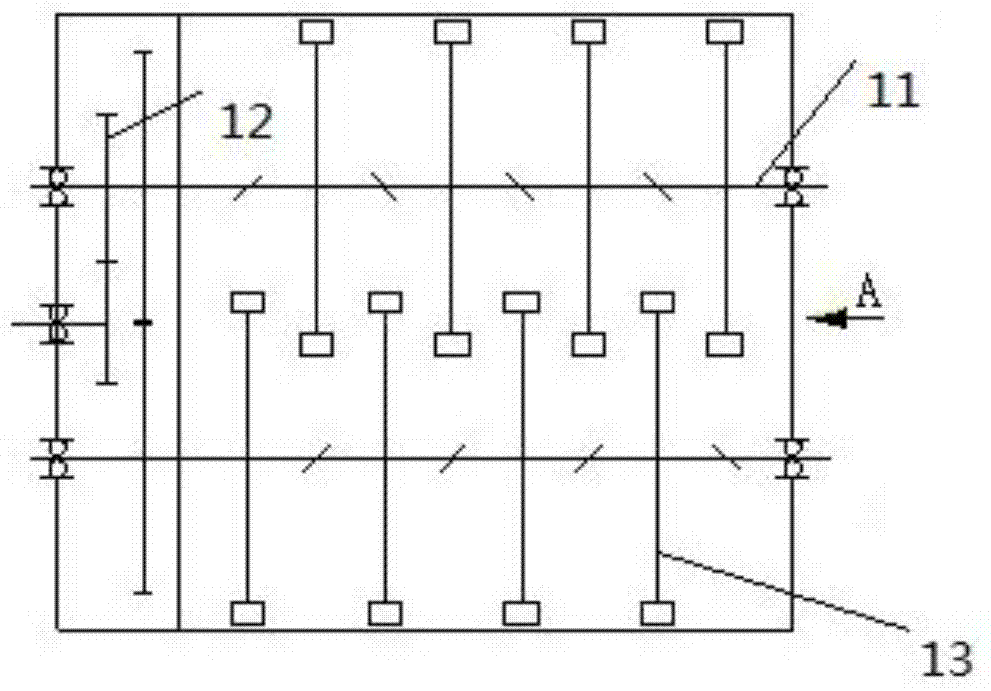

[0055] see Figure 1 to Figure 5 , the present invention comprises frame 6, and the mixer body 7 that is fixed on the frame 6 is provided with the power equipment that is fixed on the frame 6 and the unloading that makes the mixer body 7 tip over on both sides of the mixer body 7. Device; the mixing tank body 7 includes a mixing tank 9 and a gear transmission box 8 connected with the mixing tank 9, and several groups of mutually parallel stirring shafts 11 are arranged in the mixing tank 9, and a stirring arm is fixed on each group of stirring shafts 11 13. Blades 14 are fixed on the stirring arm 13; the stirring shaft 11 is connected with the gear transmission box 8; the gear transmission box 8 includes a transmission gear set 12 for transmitting power to the stirring shaft 11 and a motor for ensuring that several groups of stirring shafts 11 rotate synchronously...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com