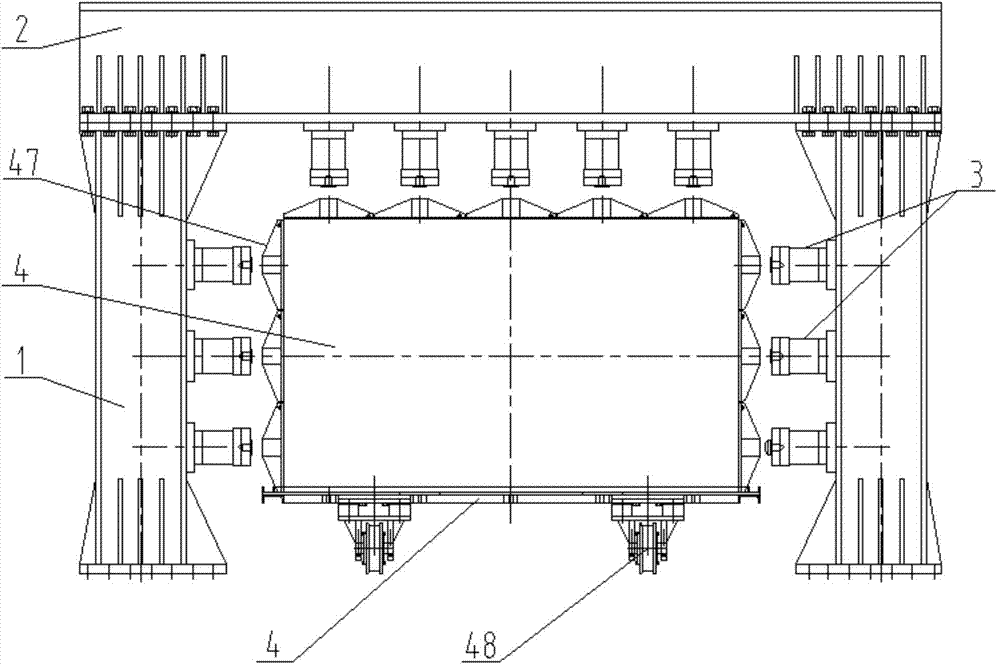

Tunnel lining structure uniform load test system and sealing method thereof

A uniformly distributed loading and test system technology, applied in the field of tunnel engineering, can solve the problems of inconsistent overall load-bearing performance, small scale, and inability to evaluate the load-bearing performance of tunnel linings, etc., to achieve the benefits of observation, improvement of test detection accuracy, and ease of evaluation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

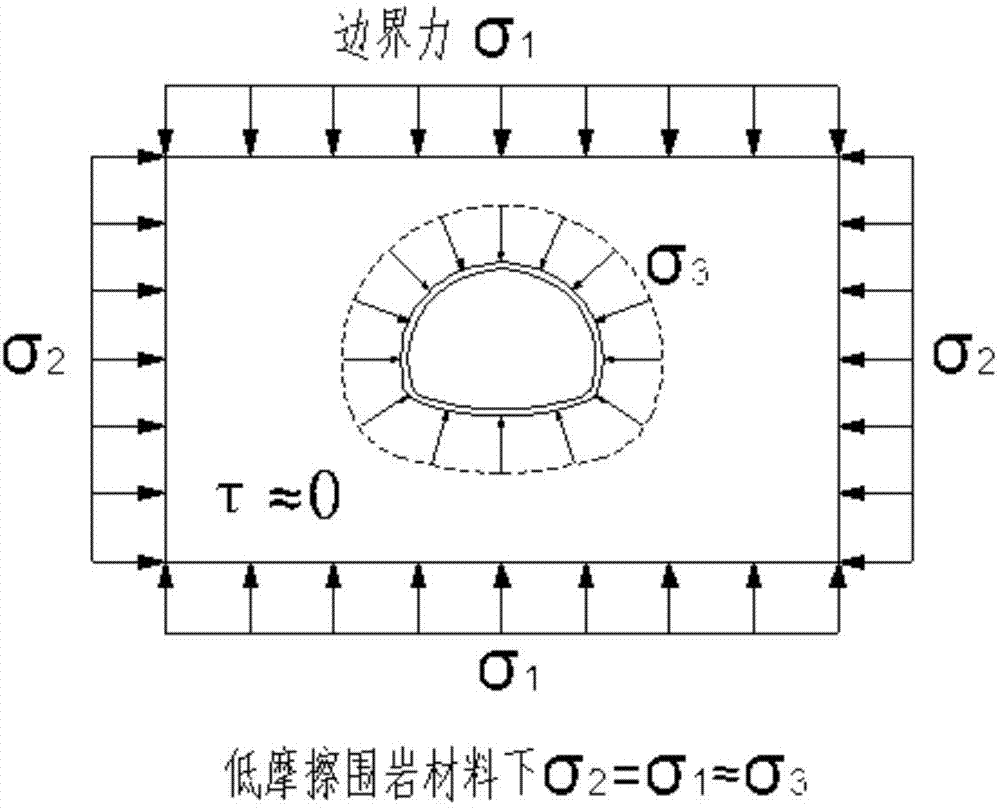

[0062] According to the similarity theory, the geometric similarity ratio is 1:10, and the stress similarity ratio is also equal to 1:10.

[0063] Boundary pressure: Make the loading stress on the vertical boundary and horizontal boundary of the model box equal, such as figure 2 As shown, that is, σ1=σ2=30kPa (according to the stress similarity ratio of 1:10, it is equivalent to 300kPa of the prototype, that is, the pressure on the lining caused by a water head height of about 30m or a filling height of 15-20m).

[0064] Tunnel lining parameters: span 1.2m, height 0.9m, thickness 5cm (according to the geometric similarity ratio of 1:10, the thickness of the V-level surrounding rock prototype of the two-lane tunnel lining is 50cm, span 12m, height 9m), elastic modulus is 2.95GPa (the prototype is C25 concrete, whose elastic modulus is 29.5GPa).

[0065] As a comparison, two materials are selected for the filling between the model box and the tunnel lining, one is soft plastic...

Embodiment 2

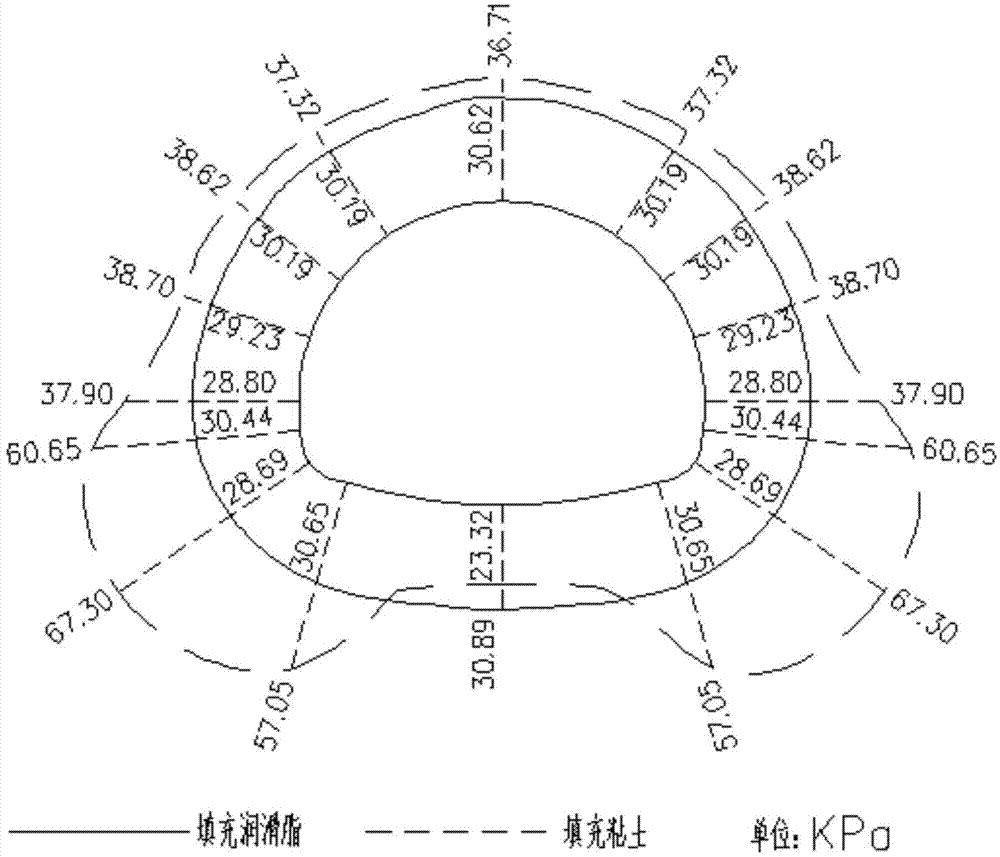

[0070] Boundary pressure: Make the loading stress on the vertical boundary and horizontal boundary of the model box equal, that is, σ1=σ2=60kPa

[0071] The rest of the conditions are exactly the same as Case 1.

[0072] The pressure distribution and its magnitude behind the tunnel lining obtained by the two filling materials are as follows: Figure 4 shown. It can be seen that when the grease is filled, the pressure around the tunnel lining is basically uniform, and compared with the boundary pressure, its maximum non-uniformity rate is 2.5%. Large stress concentration phenomenon, non-uniform rate of 175%, indicating that the filled clay can not meet the requirements of uniform loading.

[0073] The method for sealing the model box in the uniformly distributed loading test system of the above-mentioned tunnel lining structure mainly includes the following contents:

[0074] A. Use asphalt to seal and weld the gaps on the model box:

[0075] First, use hot asphalt to seal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com