Drum reaction lift type automobile axle load brake composite detecting bench and method

A reaction-force, automobile axle technology, applied in force/torque/work measuring instruments, measuring devices, instruments, etc., can solve the detection and evaluation errors of automobile axle load and braking performance, cannot detect vehicle braking performance, Vehicle driving safety hazards and other issues, to achieve the effect of stable work, improved accuracy, and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

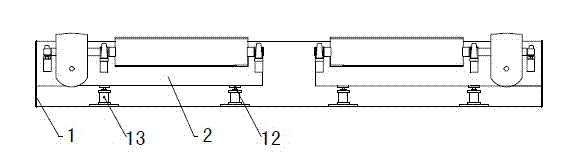

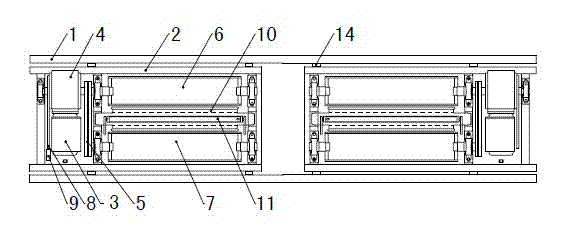

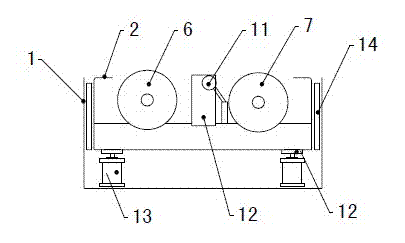

[0030] Figure 1~4 It is the best embodiment of the roller reaction force lifting type automobile axle load brake compound inspection platform and detection method, and the following is combined with the attached Figure 1~4 The present invention will be further described.

[0031] refer to Figure 1~4 , the roller reaction force lifting type automobile axle load brake composite test bench, including a mobile frame 2, a fixed frame 1 and a braking force detection device, the mobile frame 2 is set in the fixed frame 1 sliding up and down, and the fixed frame 1 is equipped with There is a lifting device that pushes the moving frame 2 up and down, and the braking force detection device is fixed on the moving frame 2. The lifting device pushes the braking force detection device up, so that the vehicle is fixed horizontally, and the angle between the vehicle and the horizontal plane is avoided, so that the vehicle can be accurately measured The braking force performance is improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com