Method for designing and manufacturing cycloid rotor pump

The technology of a cycloid rotor pump and a manufacturing method, which is applied in the directions of rotary piston pumps, pumps, pump components, etc., can solve the problems of low processing precision, high processing precision and high efficiency, and achieves improved processing efficiency, increased strength, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

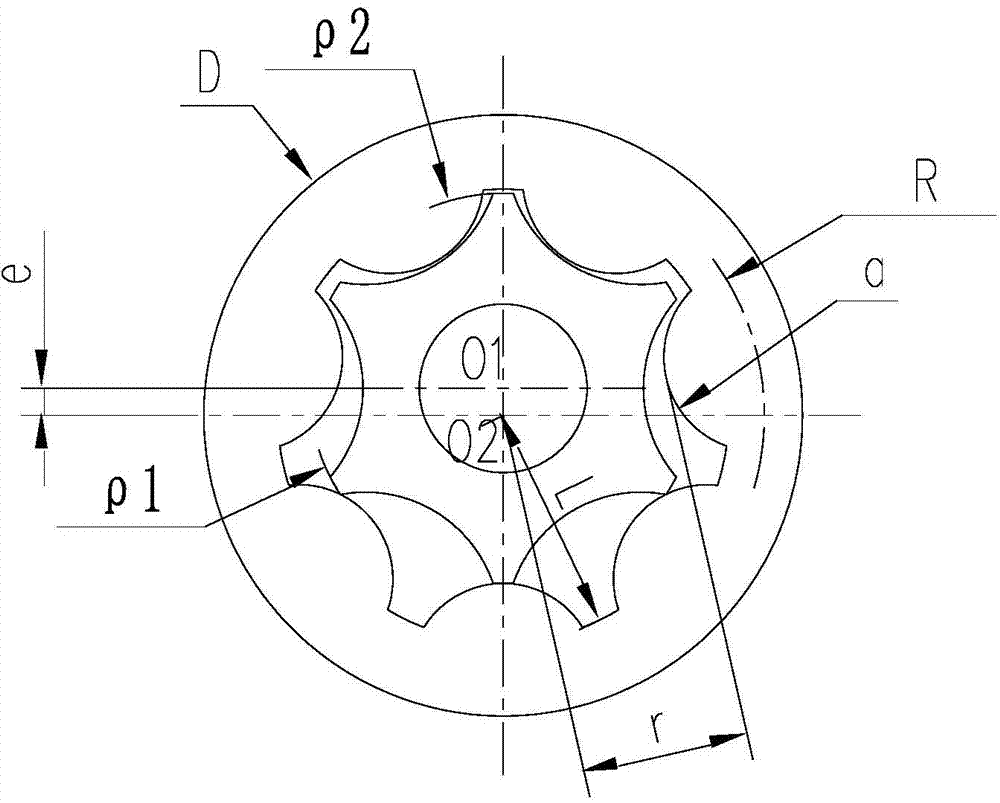

[0038] In order to better illustrate the present invention, the cycloidal rotor pump of a certain product is taken as an example below to solve the problem. The internal and external rotor parameters of a cycloidal rotor pump are known, as shown in the table below:

[0039] parameter code

Z1

R

a

e

ρ1

ρ2

parameter value

6

28

10

3

21

15

[0040] Step 1: Find the meshing inflection point of the inner and outer rotors of the cycloidal rotor pump;

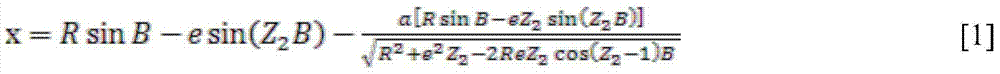

[0041] The rotor cycloid equation of the cycloid rotor pump is as follows:

[0042] x = R sin B - e sin ( Z 2 B ) - a [ R sin B - e Z ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com