Energy-saving high-pressure common-rail electronic-control oil injector

An electronically controlled fuel injection and high-pressure common rail technology, which is applied in the direction of machines/engines, fuel injection devices, engine components, etc., can solve the problem of large radial leakage of high-pressure fuel, unfavorable fuel economy of internal combustion engines, and limited space for electromagnetic force promotion, etc. problems, to achieve the effect of improving response speed, reducing the quality of moving parts, and reducing production and assembly debugging costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

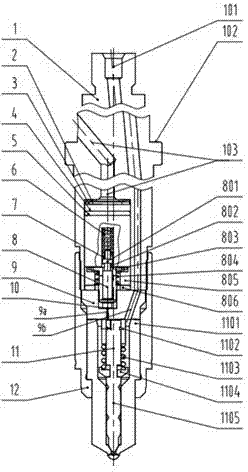

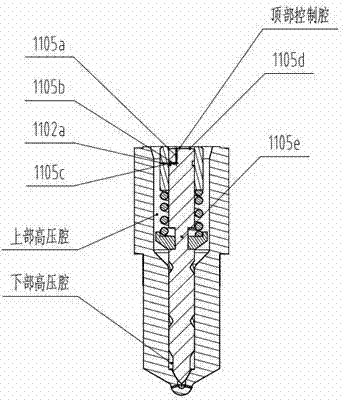

[0028] Further illustrate structure of the present invention below in conjunction with accompanying drawing:

[0029] 1. The structure of the electronically controlled fuel injector is as follows: figure 1 , Figure 1A , figure 2 with Figure 2A Shown:

[0030] The fuel injector body 1, the middle block 9, and the parts of the needle valve assembly 11 are compressed axially and sequentially through the tight cap 12 to realize high-pressure sealing. The high-speed solenoid valve 4 and the hydraulic servo mechanism 8 are installed in the middle hole of the lower part of the injector body 1, and the adjusting gasket 3, the high-speed solenoid valve and the hydraulic servo mechanism 8 are sequentially pressed on the middle block 9 through the butterfly spring 2, and the O-shaped sealing The ring 5 seals the fuel to reduce the mass of the moving parts, improve the response speed of the system, and has a simple structure and low cost.

[0031] The middle block 9 is designed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com