Sunken type impoundment flushing equipment for drainage network pipe and application of sunken type impoundment flushing equipment

A drainage network and drainage pipeline technology, applied in the field of flushing and dredging, can solve the problems of inability to adapt to secondary pollution, insufficient dredging capacity, and potential safety hazards, and achieve easy daily management, improve the efficiency of flushing and dredging, and have a wide range of applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

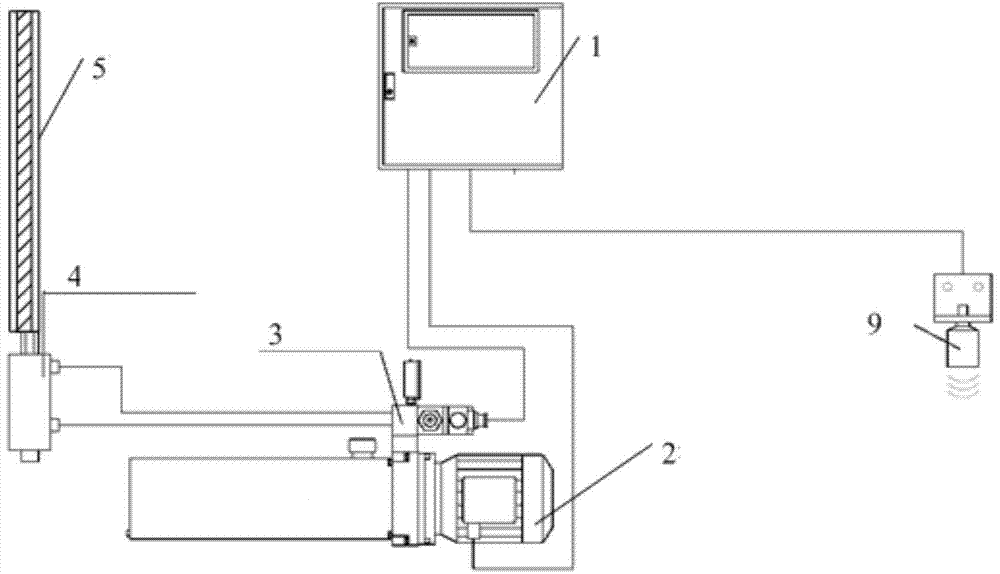

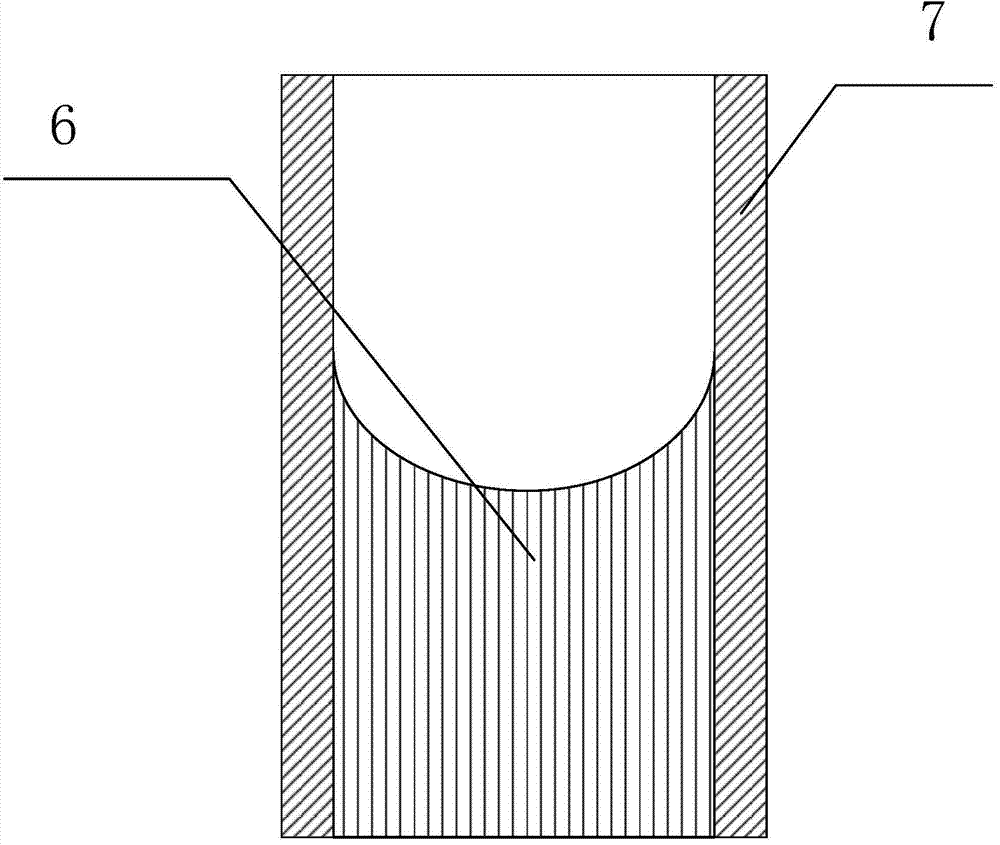

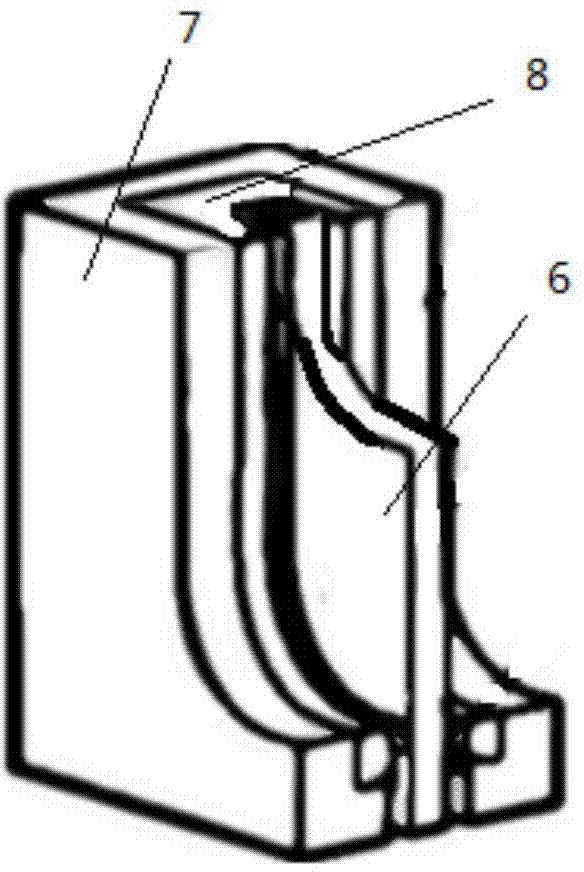

[0074] A kind of sinking storage and flushing equipment for drainage network pipes, the drainage network pipes include drainage pipes 11, such as figure 1 with Figure 4 As shown, the storage flushing equipment includes an automatic control unit 1, a liquid level gauge 9, a hydraulic pump 2, a solenoid valve 3, a hydraulic cylinder 4, a sinking storage flushing weir 5, a sinking storage flushing weir 5 and a liquid level gauge connected in sequence. The level gauge 9 is arranged in the drainage pipe 11, and the automatic control unit 1 is respectively connected with the hydraulic pump 2, the electromagnetic valve 3 and the liquid level gauge 9. The hydraulic cylinder 4 is arranged on the top of the sinking storage flushing weir 5, and the automatic control unit 1, the hydraulic pump 2, and the electromagnetic valve 3 are all located in a separate working room outside the drainage pipe 11. Among them, the parameter models of the hydraulic pump 2, electromagnetic valve 3, hydra...

Embodiment 2

[0092] The similarities between this embodiment and the first embodiment will not be described, and only the differences will be described.

[0093] The significant difference between this embodiment and Embodiment 1 is that this embodiment is an application under non-rainfall conditions, including the following steps:

[0094] A. Set the regular flushing cycle, the weir gate 6 of the sinking storage flushing weir 5 is at the bottom of the door frame 7;

[0095] B. Judging whether the set routine flushing time has been reached, if yes, then perform step E, if not, then perform step C;

[0096] C. Detect whether the amount of sediment in the drainage pipe 11 exceeds the threshold, if yes, then execute step, if no, then execute step D;

[0097] D. Keep the weir gate 6 in the same state;

[0098] E. The automatic control unit 1 controls the hydraulic pump 2, the solenoid valve 3 and the hydraulic cylinder 4 to start, and drives the weir gate 6 to rise to the storage position. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com