Composite barrier for preventing horizontal diffusion and migration of underground water layer pollutants and application thereof

A pollutant and barrier technology, applied in the field of pollutant control, can solve the problems of uneconomical use, inability to solidify cement, and limited application range, etc., and achieve the effects of simple construction, good horizontal migration, and good anti-seepage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

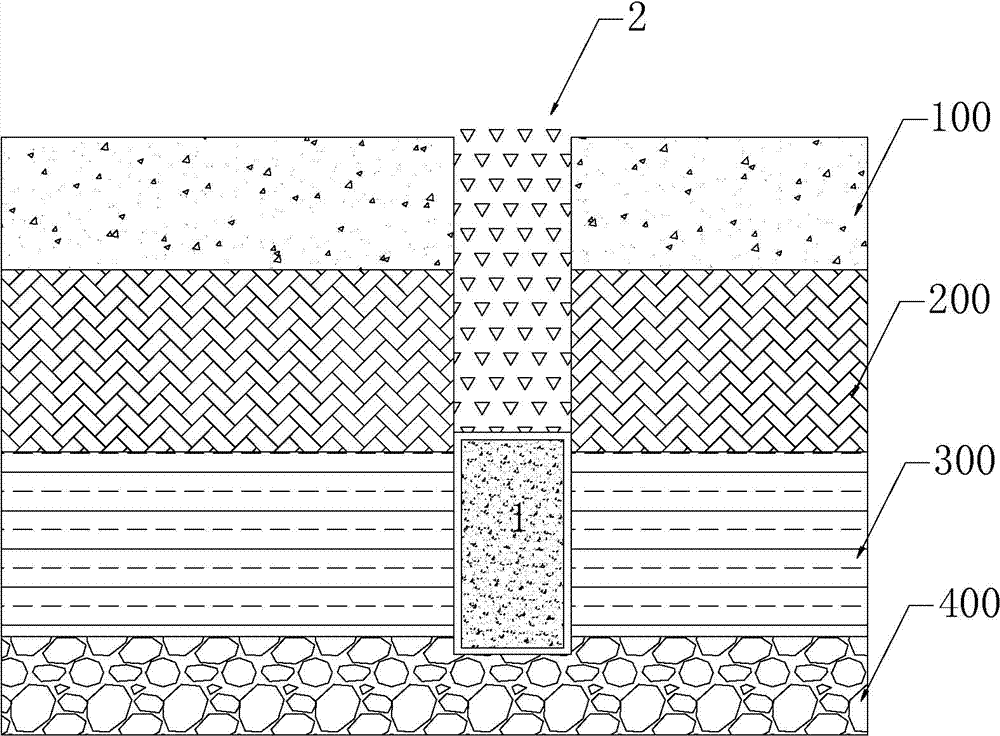

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

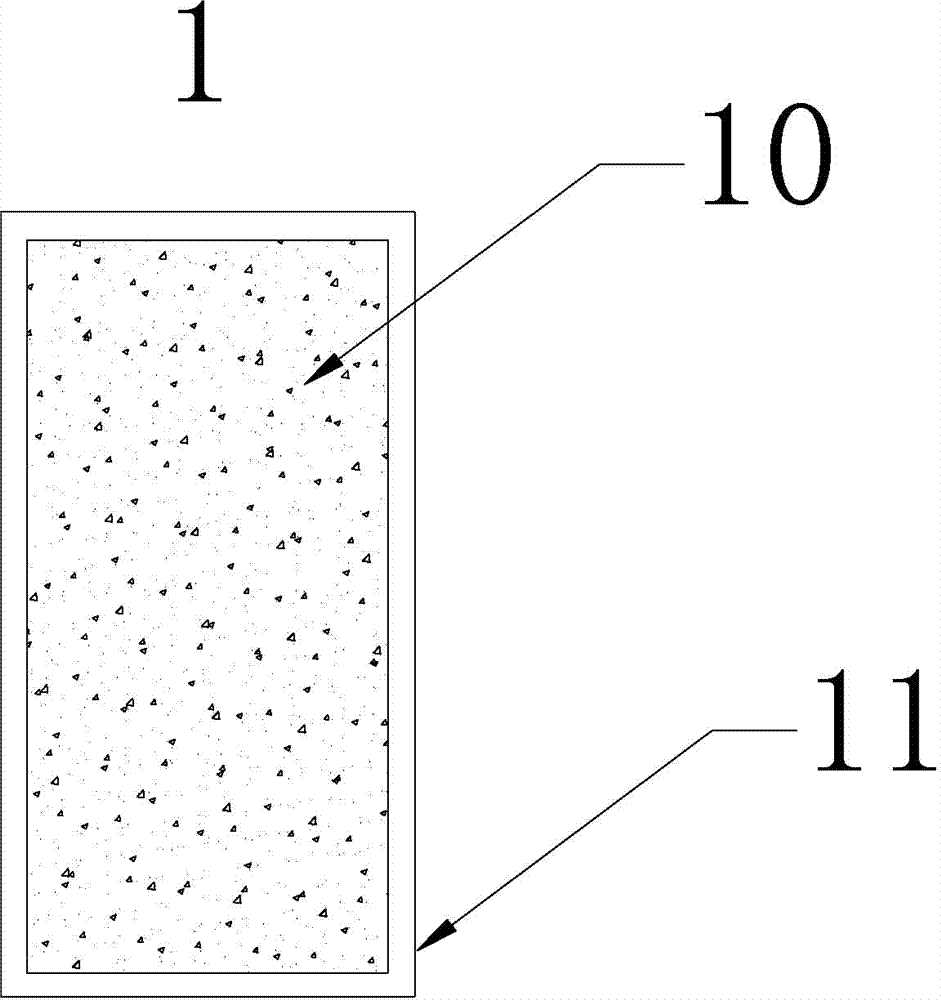

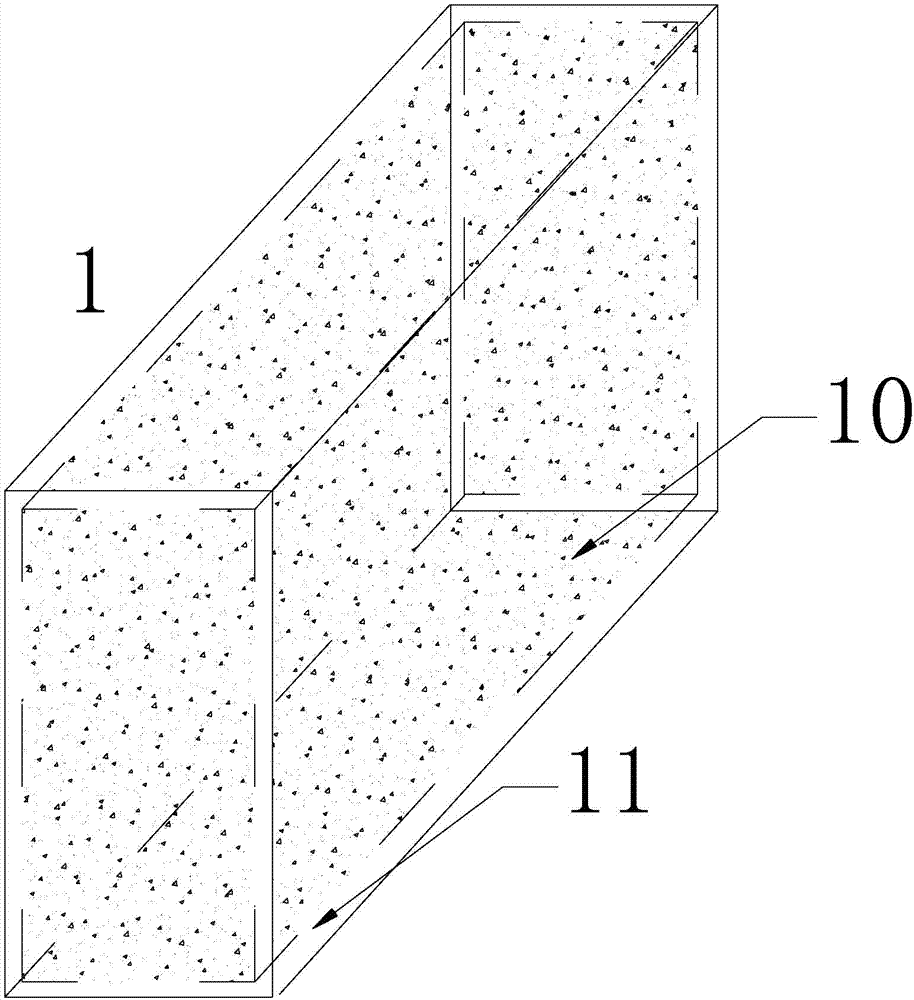

[0028] Such as figure 1 with 2 As shown, the composite barrier 1 for blocking the horizontal migration of groundwater pollutants according to the present invention is composed of a water-soluble polymer film 11 encapsulating expansive clay 10 .

[0029] The requirement of the present invention for the expansive clay 10 is that after the water-soluble polymer film 11 is dissolved, the expansive clay 10 will expand when it reacts with water, and its expansion coefficient is ≥ 10 times. The expanded clay can form a permeability coefficient ≤0.5×10 -8 cm / sec anti-seepage wall, which is used to block the horizontal migration of pollutants in the groundwater layer. Through experiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com