Method for drilling and filling concrete hollow pile

A technology of bored grouting and hollow piles, which is applied to sheet pile walls, buildings, and foundation structure engineering, etc. It can solve the problems of small pile bearing capacity and loose contact, and achieve the effect of improving pile bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be noted that the technical features or combinations of technical features described in the following embodiments should not be regarded as isolated, and they can be combined with each other to achieve better technical effects. In the drawings of the following embodiments, the same reference numerals appearing in each drawing represent the same features or components, which can be applied in different embodiments.

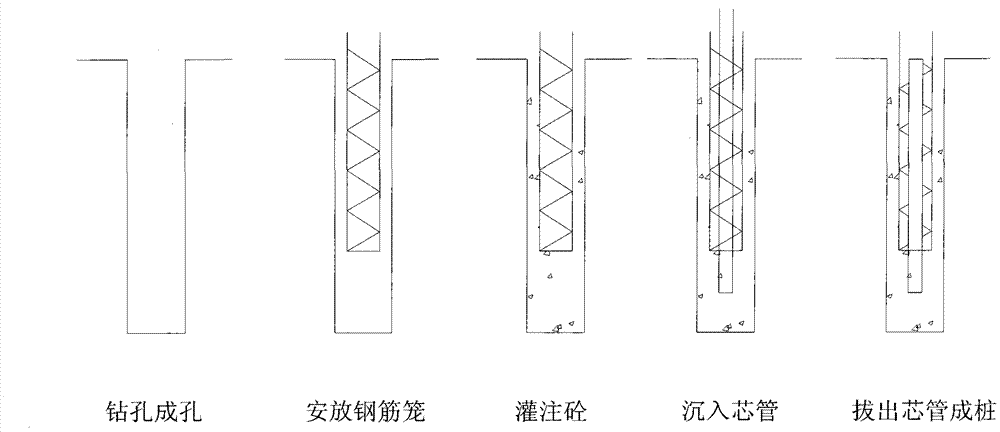

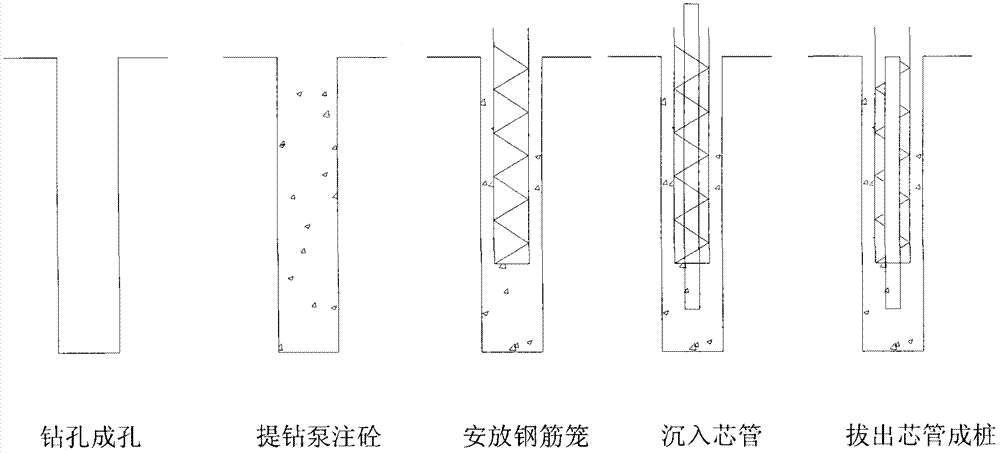

[0018] figure 1 It is a schematic diagram of the first embodiment of the method for drilling concrete hollow piles according to the present invention.

[0019] The method for drilling concrete hollow piles of the present invention comprises the following steps:

[0020] Drilling holes, that is, using long auger drills to drill holes;

[0021] Place a reinforcement cage, that is, place a reinforcement cage in the borehole, and leave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com