Multi-stage telescopic type steel dam

A steel dam and width technology, applied in the field of water retaining facilities, can solve problems such as waste, increased design, and construction difficulty, and achieve the effects of resource saving, good technical effects, economic applicability, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

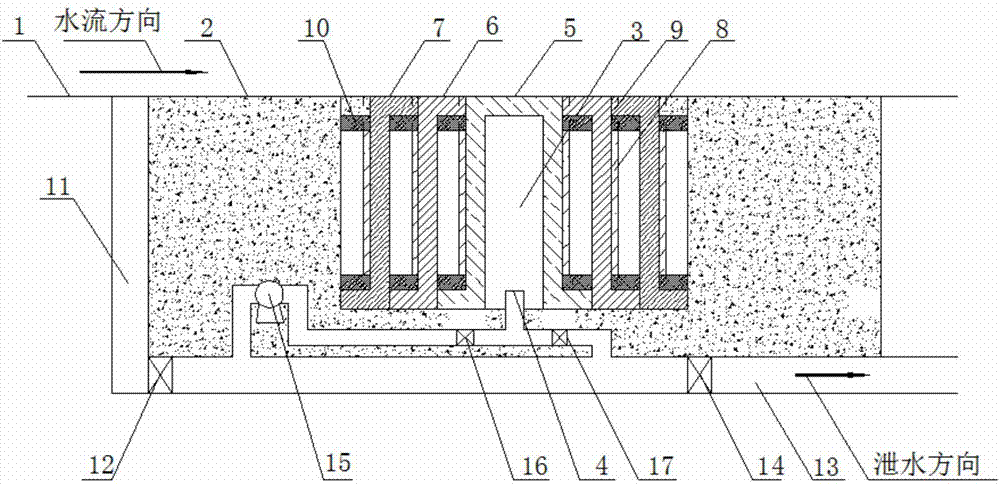

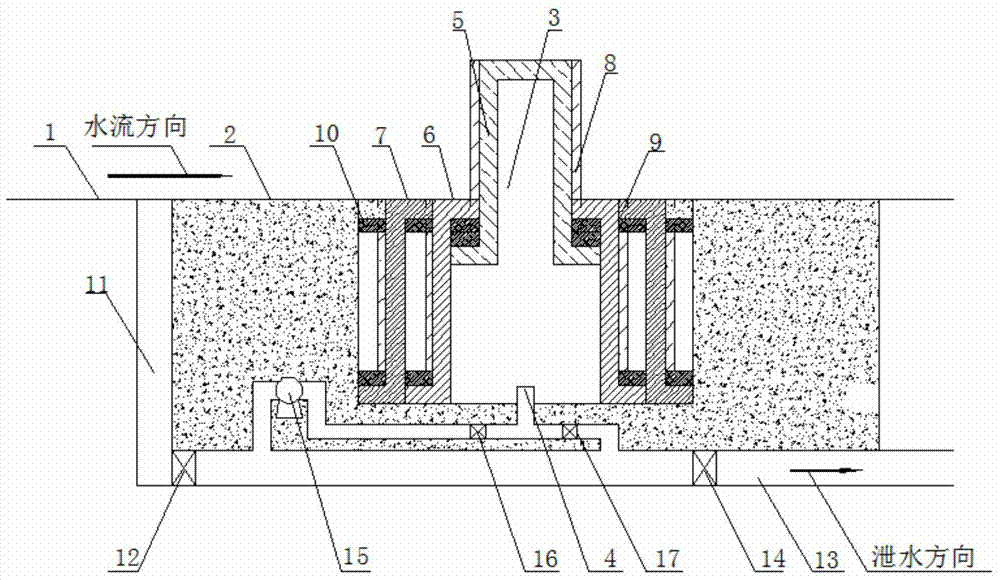

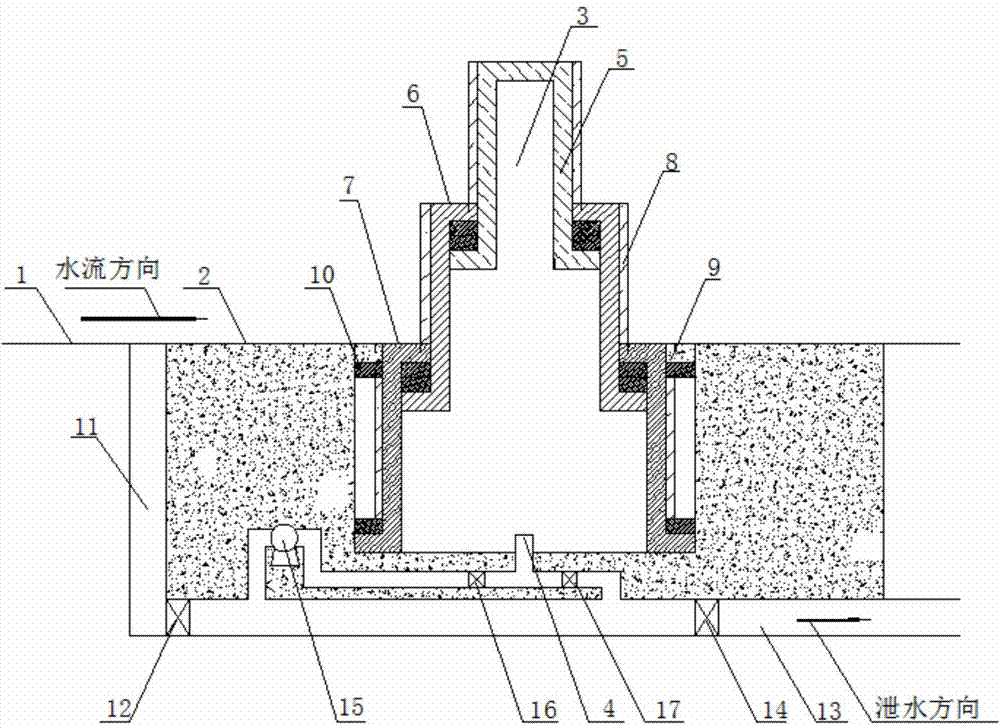

[0017] A multi-stage telescopic steel dam is set on the cross-section of the river, including the foundation part, the steel dam part and the water supply and drainage part. Steel dam groove 3, the center of the bottom of the steel dam groove is provided with a water injection port 4; the steel dam part is composed of a first-grade steel dam 5, a second-grade steel dam 6 and a third-grade steel dam 7 with the same structure, and they are sequentially set in a rectangular shape from inside to outside. In the steel dam groove 3, the first-level steel dam 5 is provided with a rectangular roof, the rectangular roof of the second-level steel dam 6 is provided with a central rectangular groove and the width of the rectangular groove is the same as that of the first-level steel dam roof, and the third-level steel dam 6 is provided with a rectangular roof. The rectangular top cover of the dam 7 is provided with a central rectangular groove and the width of the rectangular groove is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com