Carbon nano fiber paper and preparation method thereof

A technology of carbon nanofiber paper and carbon nanofiber, which is applied in the direction of fiberboard, fiber raw material processing, synthetic cellulose/non-cellulose material pulp/paper, etc., which can solve the influence of electrical conductivity, increase costs, and reduce the performance of carbon nanofibers, etc. problems, to achieve the effect of reducing production costs and high cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

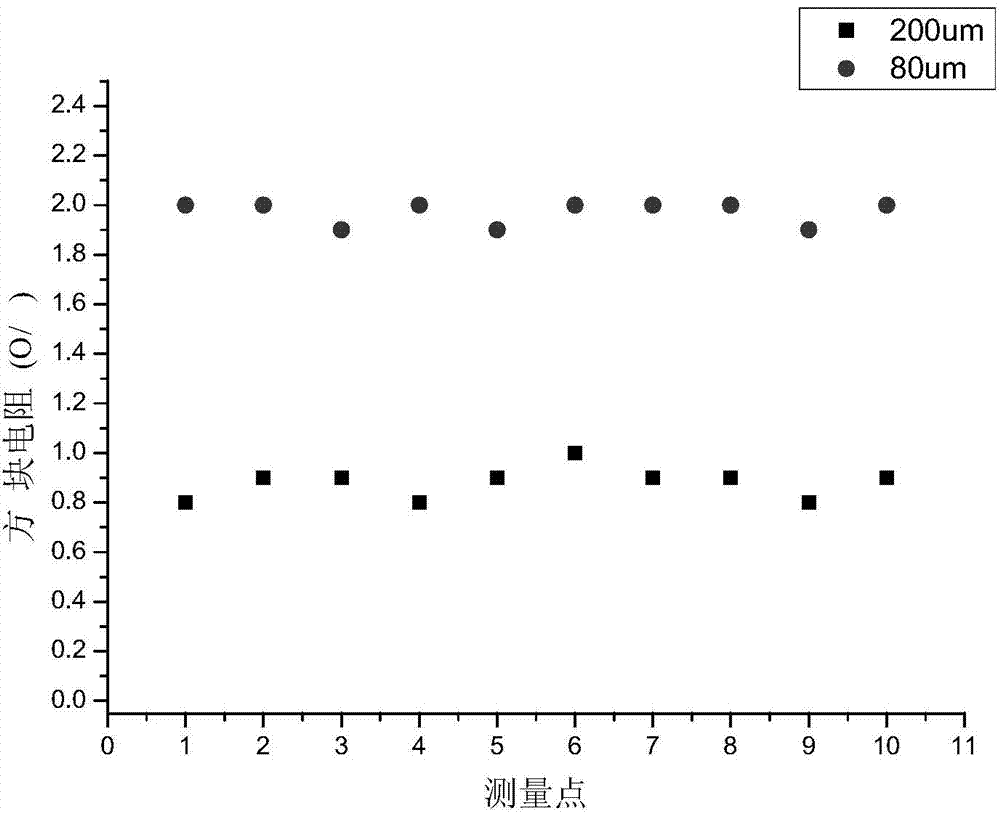

example 1

[0039] Place the multi-walled carbon nanotubes in isopropanol (IPA, >95%) solvent, the concentration of the carbon nanotube solution is 0.5mg / ml, and use the ultrasonic method to disperse the carbon nanotubes in the solvent, and the ultrasonic power is 300W After 30 minutes, the dispersed solution was homogenized by the stirring action of a high-speed mixer to make the solution uniform as a whole, and then transferred to a filter device for vacuum filtration, with a vacuum pumping rate of 2L / S, vacuum drying, and drying conditions - 0.085MPA, 85°, transfer the carbon nanofiber paper from the substrate, and optionally press it to prepare the carbon nanofiber paper.

example 2

[0041] Place the single-walled carbon nanotubes in isopropanol (IPA, >95%) solvent, the concentration of the carbon nanotube solution is 0.05mg / ml, and use the ultrasonic method to disperse the carbon nanotubes in the solvent, and the ultrasonic power is 300W After 30 minutes, the dispersed solution was homogenized by the stirring action of a high-speed mixer to make the solution uniform as a whole, and then transferred to a filter device for vacuum filtration, with a vacuum pumping rate of 2L / S, vacuum drying, and drying conditions - 0.085MPA, 85°, transfer the carbon nanofiber paper from the substrate, and optionally press it to prepare the carbon nanofiber paper.

example 3

[0043] The multi-walled carbon nanotubes and solid carbon nanofibers were placed in a mixed solvent of isopropanol and deionized water (IPA / DIW, volume ratio 1:1), the concentration of the carbon nanotube solution was 0.05mg / ml, and the ultrasonic method was used Disperse the carbon nanotubes in the solvent, the ultrasonic power is 300W, and the dispersed solution after 30 minutes is homogenized by the stirring action of a high-speed mixer to make the solution uniform as a whole, and then transferred to the filter device for vacuum filtration, vacuum pump The air extraction rate is 2L / S, vacuum drying, drying conditions -0.085MPA, 200°, transfer the carbon nanofiber paper from the substrate, and optionally press it to prepare the carbon nanofiber paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com