An anti-vibration laser lamp

A laser and anti-vibration technology, which is applied in the direction of light source, electric light source, lighting device damage prevention measures, etc., can solve the problems of returning goods, affecting the use effect of products, vibration of lamps, etc., and achieve the effect of ensuring the combined light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

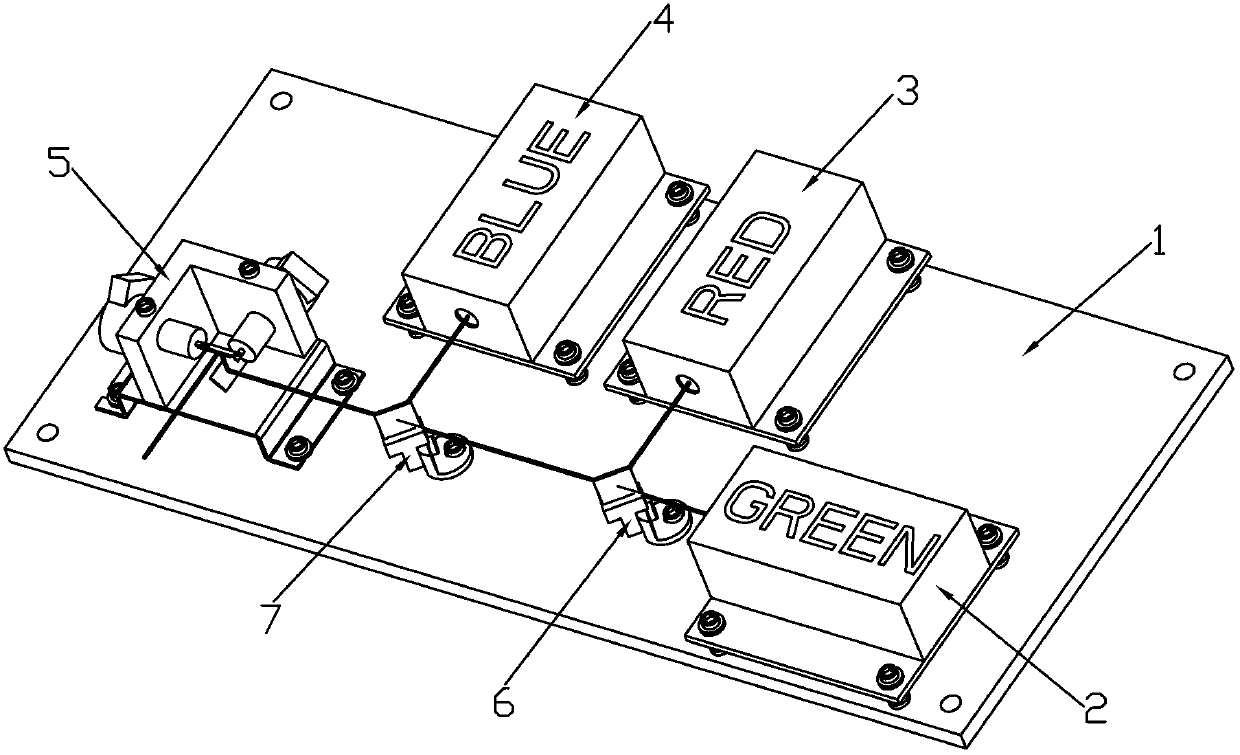

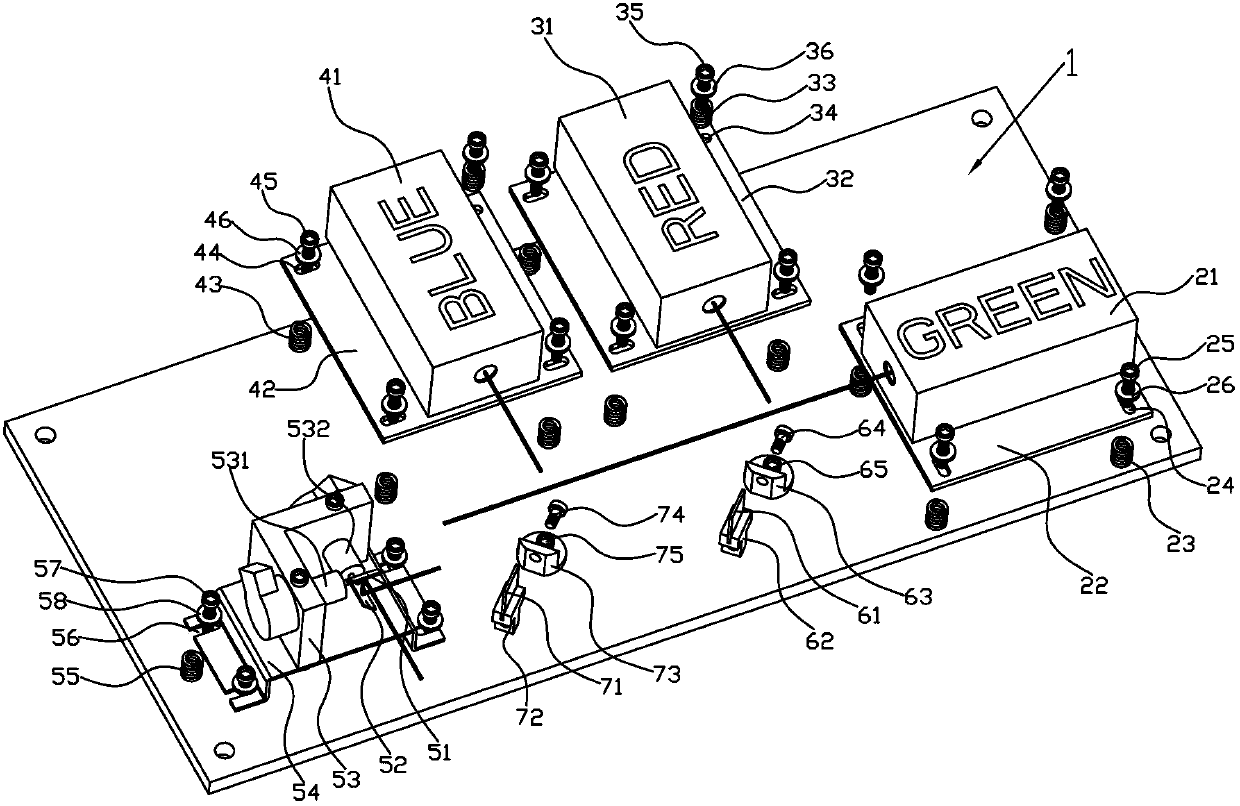

[0025] like figure 1 and figure 2 As shown, an anti-vibration laser lamp provided by the embodiment of the present invention includes an optical circuit board 1, on which a green laser group 2, a red laser group 3, a blue laser group 4, a vibrating mirror group 5, a reflector Red and green lens group 6 and anti-blue and red and green lens group 7, green laser group 2 and galvanometer group 5 are arranged oppositely, anti-red and green lens group 6 and anti-blue and red and green lens group 7 are arranged on the green Between the optical laser group 2 and the galvanometer group 5, the anti-red and green lens group 6 is set close to the green laser group 2, the anti-blue and red-transparent lens group 7 is set close to the galvanometer group 5, the green laser group 2, the anti-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com